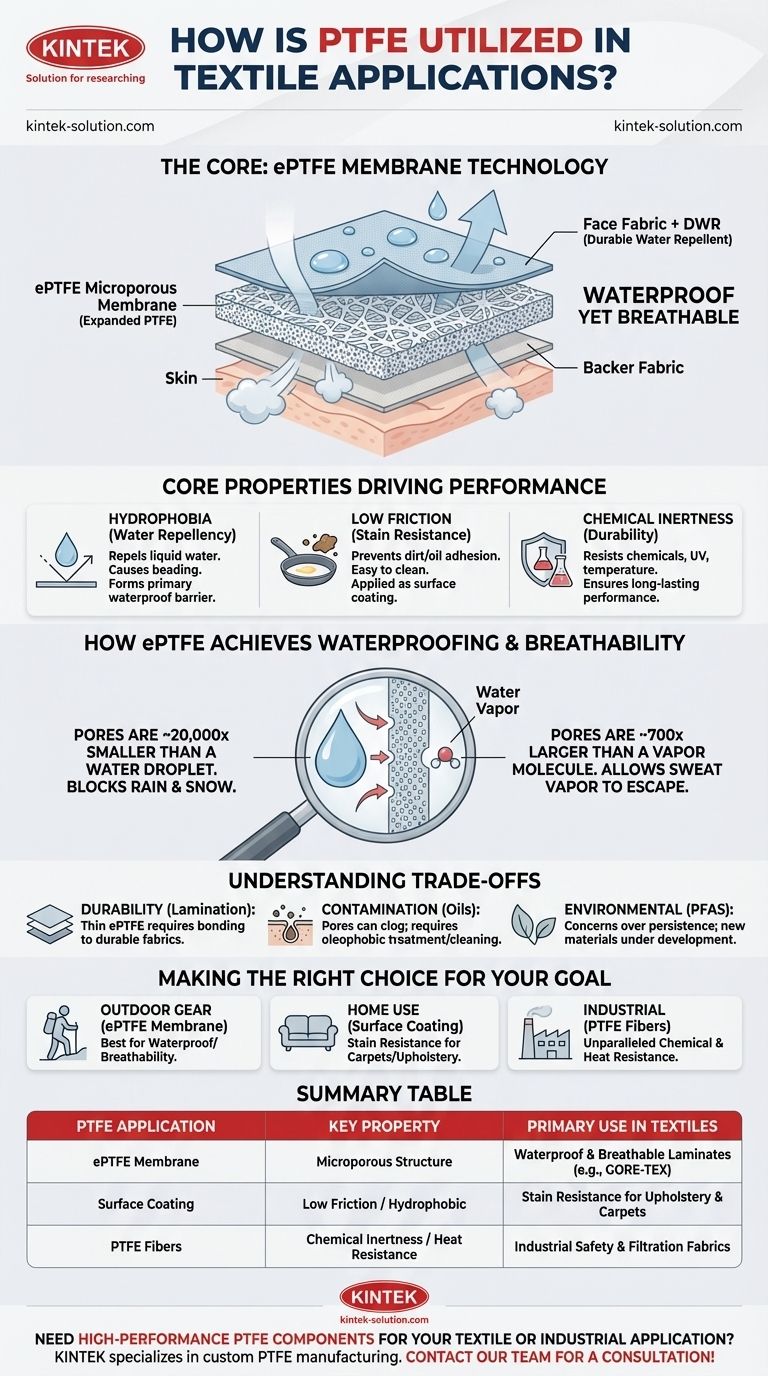

In the world of textiles, Polytetrafluoroethylene (PTFE) is primarily used to create high-performance fabrics that are waterproof, breathable, and stain-resistant. Its most notable application is in the form of expanded PTFE (ePTFE), which serves as the core technology in laminated materials like GORE-TEX, a staple in outdoor and protective apparel.

The true innovation of PTFE in textiles lies in its ability to be engineered into a microporous membrane. This structure is the key to achieving the seemingly contradictory goals of being completely waterproof against rain while remaining breathable enough to let sweat vapor escape.

The Core Properties Driving Textile Performance

To understand PTFE's role in textiles, we must first look at its fundamental chemical properties. These inherent traits are what engineers leverage to create advanced fabrics.

Inherent Hydrophobia: The Foundation of Water Repellency

PTFE is extremely hydrophobic, which means it repels water at a molecular level. This property is what causes water to bead up and roll off the surface of a treated fabric.

Instead of soaking in, liquid water is effectively blocked, forming the first line of defense in waterproof materials.

Low Friction: The Secret to Stain Resistance

The same property that makes PTFE an excellent non-stick coating for cookware also makes it highly effective for stain resistance.

Its extremely low coefficient of friction prevents oils, dirt, and other liquids from adhering to the fabric's fibers, making them easier to clean and maintain. This is often applied as a surface coating on carpets and upholstery.

Chemical Inertness: Ensuring Durability

PTFE is one of the most chemically non-reactive substances known. This means it can withstand exposure to a wide range of chemicals, UV radiation, and temperature extremes without degrading.

In textiles, this translates to exceptional durability, ensuring the fabric's performance features last through harsh weather and repeated use.

From Solid Polymer to Breathable Membrane

The most significant use of PTFE in textiles isn't as a simple coating, but as a sophisticated membrane known as expanded PTFE, or ePTFE.

What is Expanded PTFE (ePTFE)?

ePTFE is created by rapidly stretching PTFE under specific conditions. This process transforms the solid material into a microporous membrane that is over 70% air.

Think of this structure as a vast, intricate web with billions of pores per square inch. The specific size of these pores is the key to its unique function.

How it Achieves Waterproofing

The pores in an ePTFE membrane are approximately 20,000 times smaller than the smallest water droplet. This creates an impassable physical barrier for liquid water, blocking rain, snow, and wind from penetrating the fabric.

How it Achieves Breathability

At the same time, these microscopic pores are about 700 times larger than a single molecule of water vapor.

This crucial size difference allows perspiration vapor from your body to pass directly through the membrane and escape, preventing moisture buildup and keeping you dry from the inside.

Understanding the Trade-offs

While ePTFE technology is highly effective, it's important to understand its limitations to make an informed choice.

Durability and Lamination

The ePTFE membrane itself is thin and fragile. To be useful, it must be bonded, or laminated, between more durable face and backer fabrics. The quality of this lamination is critical to the garment's overall lifespan.

Contamination by Oils

The membrane's pores can become clogged by body oils, lotions, and dirt, which can compromise its breathability over time. Modern ePTFE fabrics include an oleophobic (oil-hating) treatment to mitigate this, but regular cleaning with specialized detergents is still essential for maintaining peak performance.

Environmental Considerations

PTFE is a type of per- and polyfluoroalkyl substance (PFAS), a class of chemicals that are under scrutiny for their environmental persistence. Manufacturers are actively developing new materials and recycling programs to address these concerns.

Making the Right Choice for Your Goal

Your specific need will determine which application of PTFE is most suitable for you.

- If your primary focus is high-performance outdoor gear: You need a laminated ePTFE membrane for the best possible combination of waterproofness and breathability.

- If your primary focus is everyday stain resistance for home use: A simple PTFE-based surface treatment on carpets or upholstery is a highly effective and cost-efficient solution.

- If your primary focus is industrial safety or filtration: Look for textiles woven from pure PTFE fibers, which offer unparalleled resistance to extreme heat and corrosive chemicals.

By understanding how PTFE is engineered from a simple polymer into a sophisticated membrane, you can better select the right textile for any performance-driven application.

Summary Table:

| PTFE Application | Key Property | Primary Use in Textiles |

|---|---|---|

| ePTFE Membrane | Microporous Structure | Waterproof & Breathable Laminates (e.g., GORE-TEX) |

| Surface Coating | Low Friction / Hydrophobic | Stain Resistance for Upholstery & Carpets |

| PTFE Fibers | Chemical Inertness / Heat Resistance | Industrial Safety & Filtration Fabrics |

Need High-Performance PTFE Components for Your Textile or Industrial Application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. Whether you're developing advanced laminated fabrics, industrial safety gear, or specialized filtration systems, our expertise in PTFE fabrication—from prototypes to high-volume orders—ensures the material performance and durability your products demand.

Let's discuss how our PTFE solutions can enhance your next project. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability