In the printing and packaging industry, Polytetrafluoroethylene (PTFE) is primarily utilized in the form of coated sheets and transport belts. These components are essential for processes like heat sealing, ink drying, and conveying materials, where its unique properties prevent production slowdowns and ensure a high-quality finish.

The core value of PTFE in this sector lies in its rare combination of extreme heat resistance and an exceptionally nonstick surface. This pairing allows machinery to handle hot plastics, adhesives, and wet inks without sticking, smearing, or causing contamination.

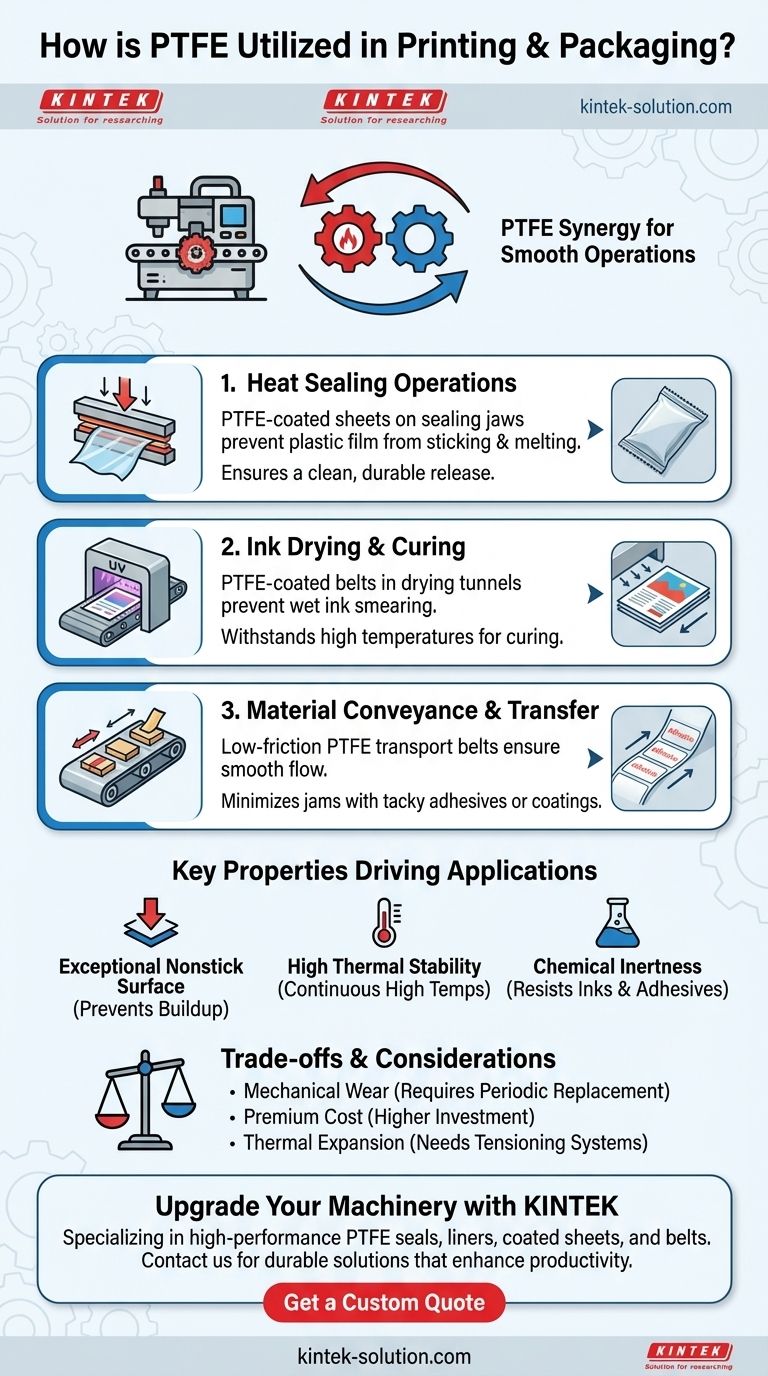

The Core Functions of PTFE in the Industry

PTFE’s role is not as a primary packaging material itself, but as a critical component within the machinery that produces and processes printed goods and packages. Its applications are targeted at solving key friction and adhesion challenges.

Heat Sealing Operations

During heat sealing, PTFE-coated sheets or tapes are used on sealing jaws and bars. The high heat required to fuse plastic packaging films would cause the plastic to melt and stick directly to the metal parts.

PTFE acts as a durable, heat-resistant, and nonstick barrier between the hot sealing element and the package, ensuring a clean release every time.

Ink Drying and Curing

After printing, materials often pass through drying or curing tunnels on conveyor belts. These belts are frequently made from fiberglass fabric coated with PTFE.

The nonstick surface prevents wet ink from smearing or transferring, while its ability to withstand high temperatures is crucial for UV or heat-based curing processes.

Material Conveyance and Transfer

The inherently low friction of PTFE makes it an ideal surface for transport belts. This ensures products, especially those with tacky adhesives or coatings, move smoothly through the production line.

This "low drag" characteristic minimizes jams and ensures consistent, efficient material flow, which is directly related to its use in industrial bearings and slide plates.

Key Properties Driving These Applications

The effectiveness of PTFE is not due to a single trait, but the synergy of several core properties that are almost perfectly suited to the demands of printing and packaging environments.

Exceptional Nonstick Surface

Much like in nonstick cookware, PTFE’s surface has very low energy, preventing other materials from adhering to it. This "release" quality is essential for preventing the buildup of inks, adhesives, and molten plastics that would otherwise halt production for cleaning.

High Thermal Stability

PTFE can operate continuously at high temperatures without degrading. This thermal resilience ensures the reliability and long service life of belts and sheets used in constant-duty heat sealing and drying applications.

Chemical Inertness

Printing inks and industrial adhesives can contain a variety of chemicals. PTFE is virtually inert, meaning it will not react with or be damaged by these substances, preserving the integrity of both the machine component and the final product.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not without its limitations. Understanding these is key to its proper implementation.

Mechanical Wear and Abrasion

PTFE is a relatively soft material. In applications with high pressure or contact with abrasive materials, PTFE coatings can wear down over time, requiring periodic replacement of the coated belts or sheets.

Cost

Compared to many other polymers and coating materials, PTFE is a premium product. The cost of PTFE-coated components is higher, which must be factored into machinery design and maintenance budgets.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. This means it expands and contracts significantly with temperature changes. Machinery design, especially for conveyor belts, must incorporate tensioning systems to account for this.

Making the Right Choice for Your Goal

When integrating PTFE components, your operational priority will determine the best application.

- If your primary focus is reliability in heat sealing: Use PTFE-coated sheets and sealer bar tapes for a durable, nonstick surface that prevents plastic film buildup and ensures clean seals.

- If your primary focus is preventing product contamination during drying: Employ PTFE-coated conveyor belts to ensure wet inks or coatings don't smear, transfer, or stick to the transport system.

- If your primary focus is smooth transport of adhesive-coated materials: Utilize PTFE-coated belts or surfaces to leverage their low-friction properties, preventing jams and ensuring consistent production flow.

Ultimately, PTFE's unique combination of properties solves the critical challenges of heat, adhesion, and friction, making it an indispensable material in high-performance printing and packaging operations.

Summary Table:

| Application | Key PTFE Function | Benefit |

|---|---|---|

| Heat Sealing | Nonstick barrier on sealing jaws | Prevents plastic buildup, ensures clean release |

| Ink Drying/Curing | Nonstick conveyor belt surface | Prevents ink smearing, withstands high temperatures |

| Material Conveyance | Low-friction transport belts | Reduces jams, ensures smooth flow of adhesive-coated materials |

Upgrade your printing and packaging machinery with precision PTFE components from KINTEK.

KINTEK specializes in manufacturing high-performance PTFE seals, liners, coated sheets, and custom conveyor belts tailored for the semiconductor, medical, laboratory, and industrial sectors. Our components are engineered to withstand extreme heat, resist chemical corrosion, and provide a superior nonstick surface—ensuring your operations run smoothly without downtime for cleaning or maintenance.

Whether you need prototypes or high-volume orders, we deliver durable, reliable solutions that enhance productivity and product quality. Contact us today to discuss how our PTFE expertise can optimize your heat sealing, drying, and conveyance processes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support