At its core, Polytetrafluoroethylene (PTFE) is indispensable in medical and pharmaceutical fields because of its unique combination of properties. In medicine, it is used for implants, surgical grafts, and as a low-friction, anti-infection coating on catheters. In pharmaceuticals, its non-stick surface is crucial for lining equipment like hoppers and tanks, ensuring product purity and process efficiency by preventing material buildup.

The immense value of PTFE in these critical sectors is not due to a single trait, but its rare ability to be simultaneously biologically inert for safe human contact and chemically inert for process integrity, all while providing superior physical performance like low friction.

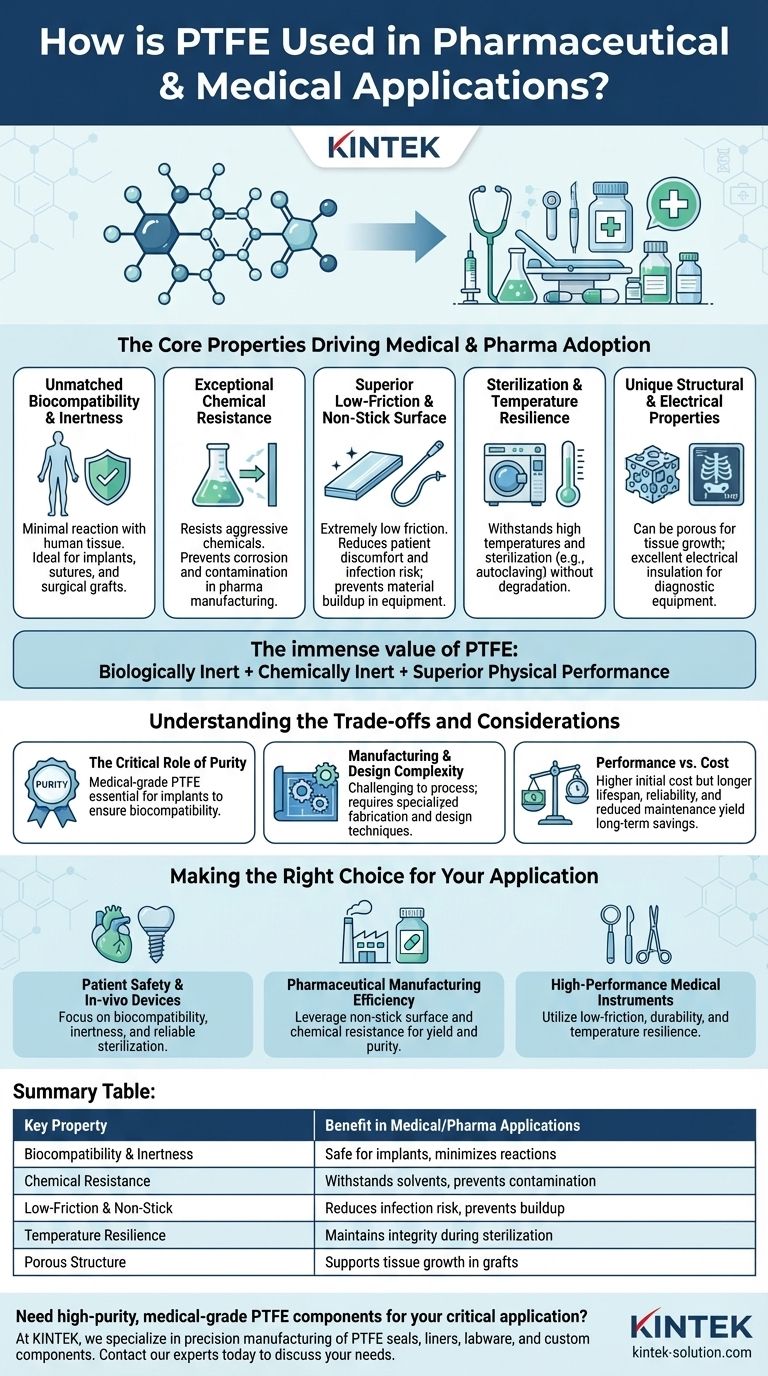

The Core Properties Driving Medical & Pharma Adoption

The widespread use of PTFE is a direct result of several key characteristics that make it uniquely suited for sensitive environments. Understanding these properties reveals why it has become a default choice for many demanding applications.

Unmatched Biocompatibility and Inertness

PTFE is exceptionally biocompatible, meaning it has a very minimal reaction with human tissue and bodily fluids.

This biological inertia makes it a prime material for implants, sutures, and surgical grafts that reside within the body for extended periods without causing adverse effects.

Exceptional Chemical Resistance

The material is highly resistant to a vast range of aggressive chemicals and solvents.

This property is critical in pharmaceutical manufacturing, where it ensures that processing equipment doesn't corrode or leach contaminants into the final product. It also allows medical devices to withstand harsh sterilization procedures repeatedly.

Superior Low-Friction and Non-Stick Surface

PTFE possesses one of the lowest coefficients of friction of any solid material, creating an extremely slick, non-stick surface.

In medicine, this is used to coat catheters and surgical tools, reducing patient discomfort and, crucially, inhibiting the ability of bacteria to adhere, which helps lower the risk of hospital-acquired infections. In pharma, this prevents powders and liquids from caking on equipment, which minimizes waste and reduces downtime for cleaning.

Sterilization and Temperature Resilience

PTFE can withstand a wide range of temperatures and is easily sterilized using methods like autoclaving without degrading.

This resilience is non-negotiable for any reusable medical instrument or component that must be guaranteed sterile before use.

Unique Structural and Electrical Properties

Beyond its surface characteristics, PTFE’s physical structure can be engineered to be porous. This is vital for medical grafts, as it supports and encourages natural cell and tissue growth.

Furthermore, its excellent electrical insulation and resistance to radiation make it suitable for components in sensitive diagnostic equipment, such as X-ray machines.

Understanding the Trade-offs and Considerations

While PTFE's benefits are clear, its successful implementation depends on understanding its context. It is not a universal solution, and its application requires precision.

The Critical Role of Purity

For any medical application, especially implants, using medical-grade PTFE is essential. This ensures a level of purity and a lack of additives that could compromise its biocompatibility.

Manufacturing and Design Complexity

The very properties that make PTFE valuable, like its chemical inertness and high melting point, also make it challenging to process.

Fabricating complex PTFE components requires specialized techniques, and the design must account for the material's unique mechanical properties to ensure long-term performance and reliability.

Performance vs. Cost

PTFE components often provide a longer lifespan, greater reliability, and reduced maintenance needs, which leads to significant long-term cost savings.

However, the initial material and manufacturing costs can be higher than those of other polymers, requiring a careful analysis of the total cost of ownership for a given application.

Making the Right Choice for Your Application

Selecting and applying PTFE effectively requires matching its specific strengths to your primary goal.

- If your primary focus is patient safety and in-vivo devices: Prioritize its proven biocompatibility, inertness, and ability to be reliably sterilized for implants, grafts, and sutures.

- If your primary focus is pharmaceutical manufacturing efficiency: Leverage its non-stick surface and chemical resistance to maximize product yield, prevent contamination, and reduce equipment downtime.

- If your primary focus is high-performance medical instruments: Utilize its low-friction properties, durability, and temperature resilience to create reliable and long-lasting surgical tools, seals, and analytical components.

Ultimately, PTFE's role in medicine and pharmaceuticals is defined by its ability to deliver safety and performance where there is no margin for error.

Summary Table:

| Key Property | Benefit in Medical/Pharma Applications |

|---|---|

| Biocompatibility & Inertness | Safe for implants, grafts, and human contact; minimizes adverse reactions. |

| Chemical Resistance | Withstands harsh solvents and sterilization; prevents product contamination. |

| Low-Friction & Non-Stick | Reduces infection risk on devices; prevents material buildup in equipment. |

| Temperature Resilience | Maintains integrity during autoclaving and other sterilization processes. |

| Porous Structure | Supports tissue growth in medical grafts for better integration. |

Need high-purity, medical-grade PTFE components for your critical application?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your components meet the strictest standards for biocompatibility, chemical resistance, and performance.

Contact our experts today to discuss how our PTFE solutions can enhance the safety and efficiency of your medical or pharmaceutical products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability