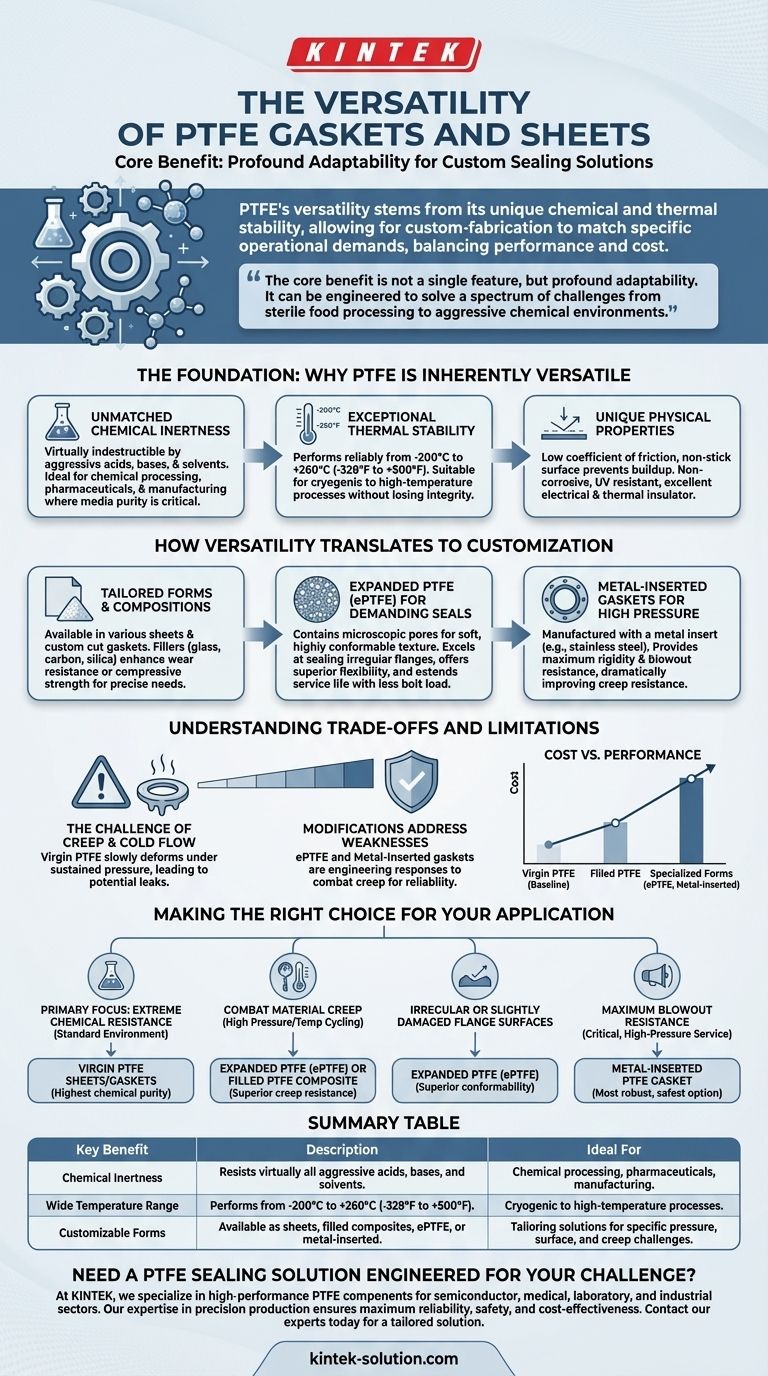

The versatility of Polytetrafluoroethylene (PTFE) gaskets and sheets is their chief benefit, stemming from a unique combination of inherent chemical and thermal stability, and an exceptional ability to be modified. This allows users to custom-fabricate sealing solutions that are precisely matched to specific operational demands, balancing performance requirements with economic considerations.

The core benefit of PTFE's versatility is not found in a single feature, but in its profound adaptability. It can be engineered in both its physical form and its material composition to solve a vast spectrum of sealing challenges, from sterile food processing to the most aggressive chemical environments.

The Foundation: Why PTFE is Inherently Versatile

PTFE, commonly known by the brand name Teflon®, possesses a set of core properties that make it a uniquely flexible material for industrial sealing. These attributes form the foundation of its widespread use.

Unmatched Chemical Inertness

PTFE is virtually indestructible by most harsh substances. It remains stable when exposed to a wide array of aggressive acids, bases, and solvents that would degrade other materials.

This property makes it a default choice for applications in chemical processing, pharmaceuticals, and manufacturing where media purity and corrosion prevention are critical.

Exceptional Thermal Stability

PTFE gaskets perform reliably across an extremely broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to be used in applications involving cryogenic liquids as well as high-temperature processes without losing its structural integrity or sealing capability.

Unique Physical Properties

Beyond its resistance, PTFE has a very low coefficient of friction, making it ideal for rotating or sliding applications. Its non-stick surface simplifies cleaning and prevents media buildup.

Furthermore, it is non-corrosive, does not age or degrade from UV radiation, and serves as an excellent electrical and thermal insulator.

How Versatility Translates to Customization

The true power of PTFE is realized through manufacturing. Its base properties can be enhanced and tailored to overcome specific challenges, moving it from a general-purpose material to a high-performance, specialized solution.

Tailored Forms and Compositions

PTFE is readily available in sheets of various thicknesses that can be cut into custom gaskets for any pipe size or equipment flange.

Manufacturers can also introduce fillers (such as glass, carbon, or silica) into the PTFE matrix. These fillers enhance specific properties like wear resistance or compressive strength to meet precise operational needs.

Expanded PTFE (ePTFE) for Demanding Seals

Expanded PTFE is a structurally different form of the material that contains microscopic pores. This gives it a soft, highly conformable texture.

ePTFE excels at sealing irregular or damaged flange surfaces. It offers superior flexibility and compression resilience, creating a tight seal with less bolt load and extending the service life of the connection.

Metal-Inserted Gaskets for High Pressure

For applications requiring maximum rigidity and blowout resistance, PTFE can be manufactured with a metal insert, typically made of stainless steel.

This structural reinforcement dramatically improves the gasket's ability to resist the primary weakness of standard PTFE: creep.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the limitations of PTFE is key to using it effectively and choosing the right variant for the job.

The Challenge of Creep and Cold Flow

The main drawback of virgin (unfilled) PTFE is its tendency to creep, or "cold flow," under the sustained pressure of a bolted flange. This means the material slowly deforms over time, which can lead to a loss of sealing pressure and potential leaks.

How Modifications Address Weaknesses

This is where versatility becomes a problem-solver. The creation of expanded PTFE (ePTFE) and the use of fillers are direct engineering responses to combat creep.

ePTFE’s structure provides significantly better creep resistance. Likewise, metal-inserted gaskets provide a rigid backbone that almost completely eliminates cold flow, making them suitable for high-pressure and critical service.

Cost vs. Performance

There is a direct relationship between performance and cost. Virgin PTFE is a baseline, filled PTFE offers a moderate increase in performance and cost, and specialized forms like ePTFE or metal-inserted gaskets represent a higher investment for critical applications.

Making the Right Choice for Your Application

Selecting the correct PTFE material is a matter of aligning its properties with the primary challenge of your sealing environment.

- If your primary focus is extreme chemical resistance in a standard environment: Virgin PTFE sheets or gaskets provide the highest level of chemical purity.

- If you need to combat material creep from high pressure or temperature cycling: Expanded PTFE (ePTFE) or a filled PTFE composite is the superior choice.

- If your application has irregular or slightly damaged flange surfaces: The superior conformability of expanded PTFE (ePTFE) will provide the most reliable seal.

- If you require maximum blowout resistance for a critical, high-pressure service: A metal-inserted PTFE gasket is the most robust and safest option.

By understanding how PTFE's fundamental properties can be modified, you can select a sealing solution engineered for reliability, safety, and longevity.

Summary Table:

| Key Benefit | Description | Ideal For |

|---|---|---|

| Chemical Inertness | Resists virtually all aggressive acids, bases, and solvents. | Chemical processing, pharmaceuticals, manufacturing. |

| Wide Temperature Range | Performs from -200°C to +260°C (-328°F to +500°F). | Cryogenic to high-temperature processes. |

| Customizable Forms | Available as sheets, filled composites, ePTFE, or metal-inserted. | Tailoring solutions for specific pressure, surface, and creep challenges. |

Need a PTFE sealing solution engineered for your specific challenge?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom gaskets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution that delivers maximum reliability, safety, and cost-effectiveness.

Contact our experts today to discuss your application requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications