At its core, the non-stick surface of Polytetrafluoroethylene (PTFE) Teflon washers is a fundamental engineering property that prevents other substances from adhering to them. This characteristic is critical in applications where preventing contamination, reducing friction, and ensuring easy maintenance are paramount, particularly in hygienic or high-performance industrial settings.

The non-stick nature of a PTFE washer is not merely a convenience feature; it is the source of its key benefits, directly translating into lower friction in mechanical systems and superior purity in sensitive processing environments.

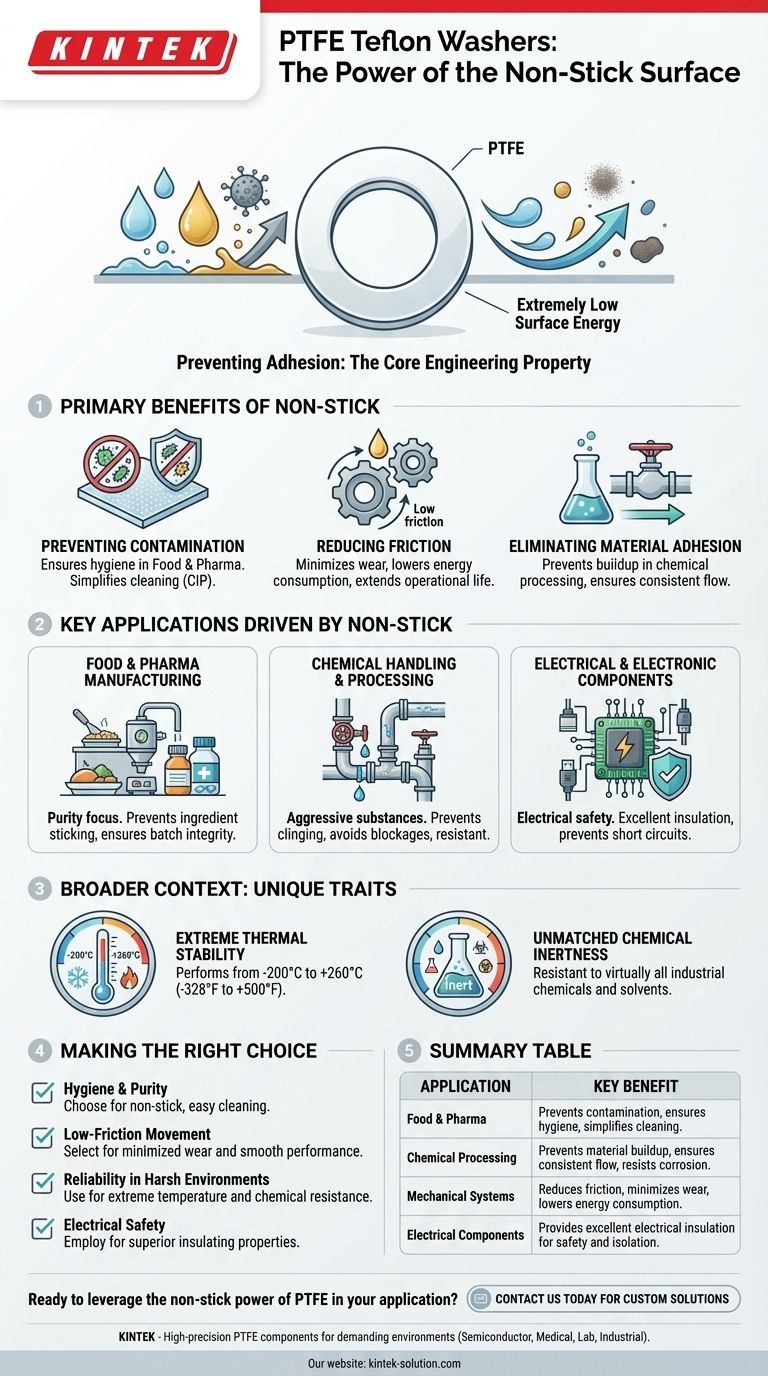

The Primary Benefit: Eliminating Material Adhesion

The value of a PTFE washer's non-stick surface stems from its extremely low surface energy. This molecular property makes it difficult for other materials—from sticky food products to aggressive chemicals—to find a foothold and bond with the washer's surface.

Preventing Contamination and Ensuring Hygiene

In industries like food processing, pharmaceuticals, and biotechnology, preventing cross-contamination is non-negotiable.

The non-stick surface ensures that product residues do not build up on gaskets, seals, or other components. This lack of adhesion drastically simplifies cleaning and sterilization processes, ensuring a higher standard of hygiene and product purity.

Reducing Friction in Mechanical Systems

The non-stick characteristic is directly linked to PTFE's famously low coefficient of friction.

In dynamic applications such as bearings, seals, and conveyor systems, this property allows mating surfaces to move smoothly against the washer with minimal resistance. This reduces wear and tear, lowers energy consumption, and extends the operational life of the machinery.

How Non-Stick Properties Drive Key Applications

The utility of the non-stick surface becomes clear when viewed in the context of specific industrial challenges. It is often the primary reason PTFE is selected over other materials.

Food Processing and Pharmaceutical Manufacturing

Here, the goal is purity. The non-stick surface prevents ingredients or chemical compounds from sticking to gaskets and seals. This ensures batch integrity and makes clean-in-place (CIP) procedures far more effective and reliable.

Chemical Handling and Processing

PTFE's non-stick nature, combined with its chemical inertness, makes it ideal for handling aggressive or viscous substances. It prevents materials from clinging to the inside of pipework, valves, and containers, ensuring consistent flow and preventing blockages.

Electrical and Electronic Components

While not a direct function of being "non-stick," PTFE's excellent electrical insulation properties are a critical feature. The material's inability to conduct electricity prevents short circuits, making PTFE washers essential for safely isolating components in connectors and terminals.

Understanding the Broader Context of PTFE

The non-stick surface does not exist in isolation. It is part of a powerful combination of traits that make PTFE a uniquely versatile engineering material.

Extreme Thermal Stability

PTFE washers perform reliably across an exceptionally wide temperature range, from -200°C to +260°C (-328°F to +500°F). This means the non-stick property remains effective in environments where other polymers would fail.

Unmatched Chemical Inertness

PTFE is resistant to virtually all industrial chemicals and solvents. This ensures the washer will not degrade, swell, or contaminate a process, allowing its non-stick surface to perform reliably in corrosive environments.

Making the Right Choice for Your Application

To leverage PTFE effectively, match its properties to your primary engineering goal.

- If your primary focus is hygiene and purity: Choose PTFE for its non-stick surface, which prevents material buildup and guarantees easy, effective cleaning.

- If your primary focus is low-friction mechanical movement: Select PTFE for its non-stick, low-friction characteristics to minimize wear and ensure smooth, reliable performance in bearings and seals.

- If your primary focus is reliability in harsh environments: Use PTFE because its non-stick property is maintained across extreme temperatures and in the presence of aggressive chemicals.

- If your primary focus is electrical safety: Employ PTFE washers for their superior insulating properties to prevent electrical conductivity and ensure component isolation.

Understanding how this single non-stick property creates cascading benefits is the key to deploying PTFE washers for maximum engineering advantage.

Summary Table:

| Application | Key Benefit of Non-Stick Surface |

|---|---|

| Food & Pharma | Prevents contamination, ensures hygiene, simplifies cleaning. |

| Chemical Processing | Prevents material buildup, ensures consistent flow, resists corrosion. |

| Mechanical Systems | Reduces friction, minimizes wear, lowers energy consumption. |

| Electrical Components | Provides excellent electrical insulation for safety and isolation. |

Ready to leverage the non-stick power of PTFE in your application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom fabrication services—from prototypes to high-volume orders—ensure you get the exact solution for demanding environments where purity, low friction, and chemical resistance are critical.

Contact us today to discuss how our PTFE components can solve your specific engineering challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments