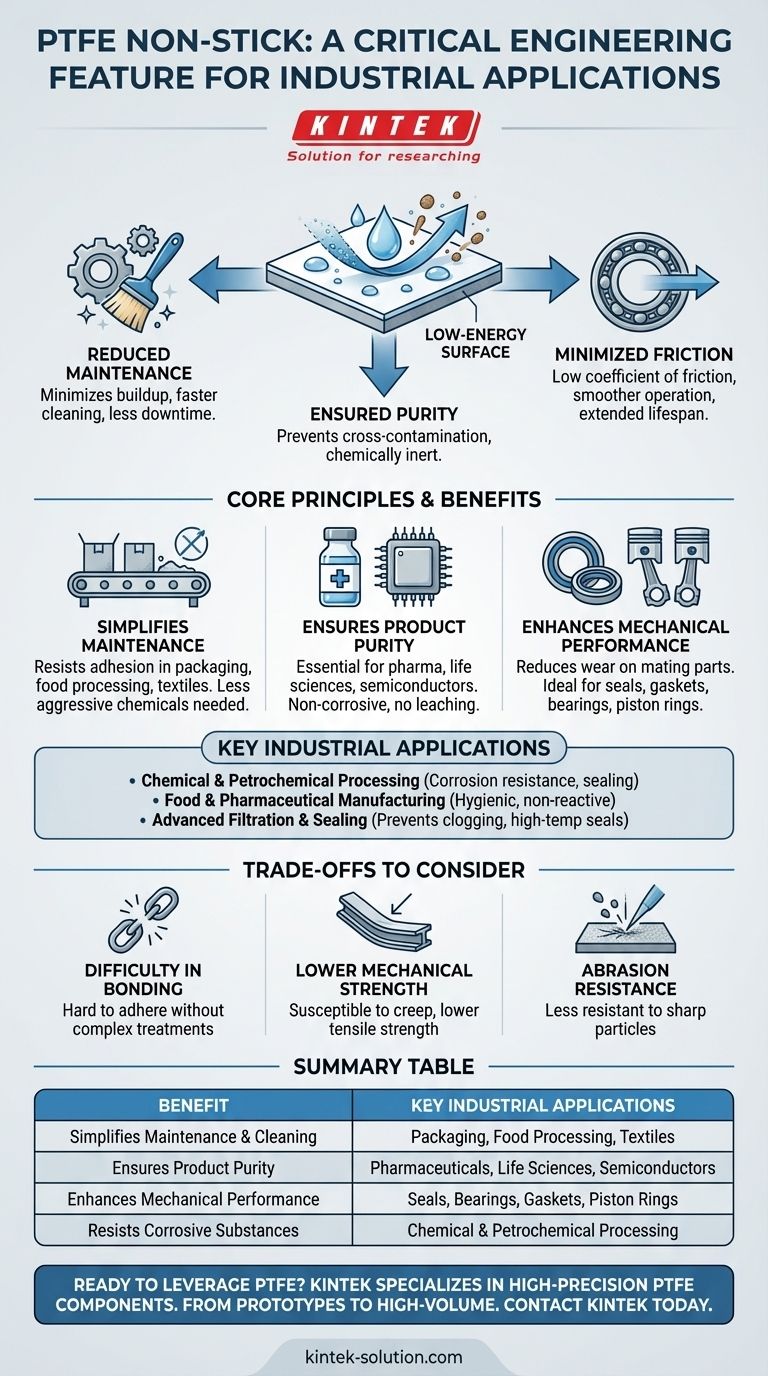

In industrial applications, the non-stick property of Polytetrafluoroethylene (PTFE) is a critical engineering feature that prevents substances from adhering to surfaces. This fundamental characteristic directly reduces maintenance overhead, minimizes friction in mechanical systems, and ensures the purity of materials in sensitive processes.

The true value of PTFE's non-stick surface goes beyond simple convenience. It is a core functional property that drives operational efficiency, extends the lifespan of components, and protects product integrity across a wide range of demanding industrial environments.

The Core Principle: Preventing Adhesion

The primary benefit of PTFE’s non-stick nature is its ability to create a low-energy surface to which other materials struggle to bond. This simple principle has profound impacts on maintenance, product quality, and mechanical performance.

Simplifying Maintenance and Cleaning

A non-stick surface inherently resists the buildup of process materials, residues, and contaminants. This is invaluable in industries like packaging, food processing, and textiles.

Because substances do not adhere, equipment cleaning is faster and requires less aggressive chemicals or mechanical force. This translates directly to reduced operational downtime and lower maintenance costs.

Ensuring Product Purity

In industries where purity is non-negotiable, such as pharmaceuticals, life sciences, and semiconductors, PTFE is essential. Its non-stick surface prevents cross-contamination between batches.

Furthermore, its non-corrosive nature means it won't react with or leach into the products it contacts, whether they are aggressive chemicals, solvents, or sensitive biologics.

Enhancing Mechanical Performance

In mechanical applications, the "non-stick" property manifests as an extremely low coefficient of friction. This quality is crucial for components that move against each other.

By reducing wear on mating surfaces, PTFE ensures smoother, more efficient performance in parts like seals, gaskets, bearings, and piston rings, ultimately extending the life of the machinery.

Where Non-Stick Properties Drive Value

The practical benefits of a non-stick, low-friction material are realized in some of the most challenging industrial sectors.

Chemical and Petrochemical Processing

PTFE components are used to handle highly corrosive chemicals, mineral oils, solvents, and other aggressive media. The material’s inability to be "wetted" by these substances prevents them from sticking and causing degradation, ensuring reliable sealing and transport.

Food and Pharmaceutical Manufacturing

The combination of being non-stick and non-corrosive makes PTFE ideal for food-grade applications and pharmaceutical research. It is used to seal vials containing APIs, line reactors, and in chromatography systems where preventing sample adhesion is critical for accurate results.

Advanced Filtration and Sealing

Expanded PTFE (ePTFE) is used in high-performance filters and sealing applications, such as chemical pipe flanges. Its non-stick nature prevents filter pores from clogging and ensures that gaskets create a clean, tight seal without bonding to the flange surfaces, even at high temperatures.

Understanding the Trade-offs

While its non-stick property is a significant advantage, it's important to recognize the associated limitations of PTFE to make an informed material choice.

Difficulty in Bonding

The very characteristic that makes PTFE non-stick also makes it extremely difficult to bond to other materials using conventional adhesives. Applying it as a coating or bonding it to a substrate often requires complex and costly surface treatments like chemical etching.

Lower Mechanical Strength

Compared to metals or other engineering plastics, PTFE is a relatively soft material. It can be susceptible to creep (deformation under sustained load) and has lower tensile strength, which can be a limitation in high-load structural applications.

Abrasion Resistance

While PTFE has excellent low-friction properties, it is not highly resistant to abrasion from hard, sharp particles. In environments with significant abrasive media, the material can wear away more quickly than harder alternatives.

Making the Right Choice for Your Goal

Selecting PTFE is a strategic decision that should align with your primary engineering objective.

- If your primary focus is reducing maintenance and downtime: PTFE's non-stick surface minimizes residue buildup, making it ideal for packaging, textiles, and food processing lines.

- If your primary focus is ensuring product purity: The inert and non-stick nature of PTFE is essential for applications in pharmaceuticals, life sciences, and semiconductor manufacturing.

- If your primary focus is enhancing mechanical efficiency: PTFE's low-friction characteristic reduces wear and improves performance in dynamic components like bearings, seals, and slide plates.

Ultimately, leveraging PTFE's non-stick property is a direct investment in the reliability, purity, and efficiency of your industrial process.

Summary Table:

| Benefit | Key Industrial Applications |

|---|---|

| Simplifies Maintenance & Cleaning | Packaging, Food Processing, Textiles |

| Ensures Product Purity | Pharmaceuticals, Life Sciences, Semiconductors |

| Enhances Mechanical Performance | Seals, Bearings, Gaskets, Piston Rings |

| Resists Corrosive Substances | Chemical & Petrochemical Processing |

Ready to leverage PTFE's non-stick properties in your application?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We deliver custom fabrication from prototypes to high-volume orders, ensuring your process achieves maximum reliability, purity, and efficiency.

Contact KINTEK today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability