Ultimately, a manufacturer's reputation is a direct indicator of a septum's reliability and consistency. A reputable supplier with stringent quality assurance (QA) protocols provides confidence that the septum will perform as expected, safeguarding your analysis from contamination, sample loss, and variability. This choice ensures the accuracy and reproducibility essential for professional lab work.

Choosing a septum is not merely a consumable purchase; it is a critical decision that impacts the validity of your data. Manufacturer reputation and quality assurance act as your primary insurance against inconsistent materials, which can lead to failed analyses, wasted time, and compromised results.

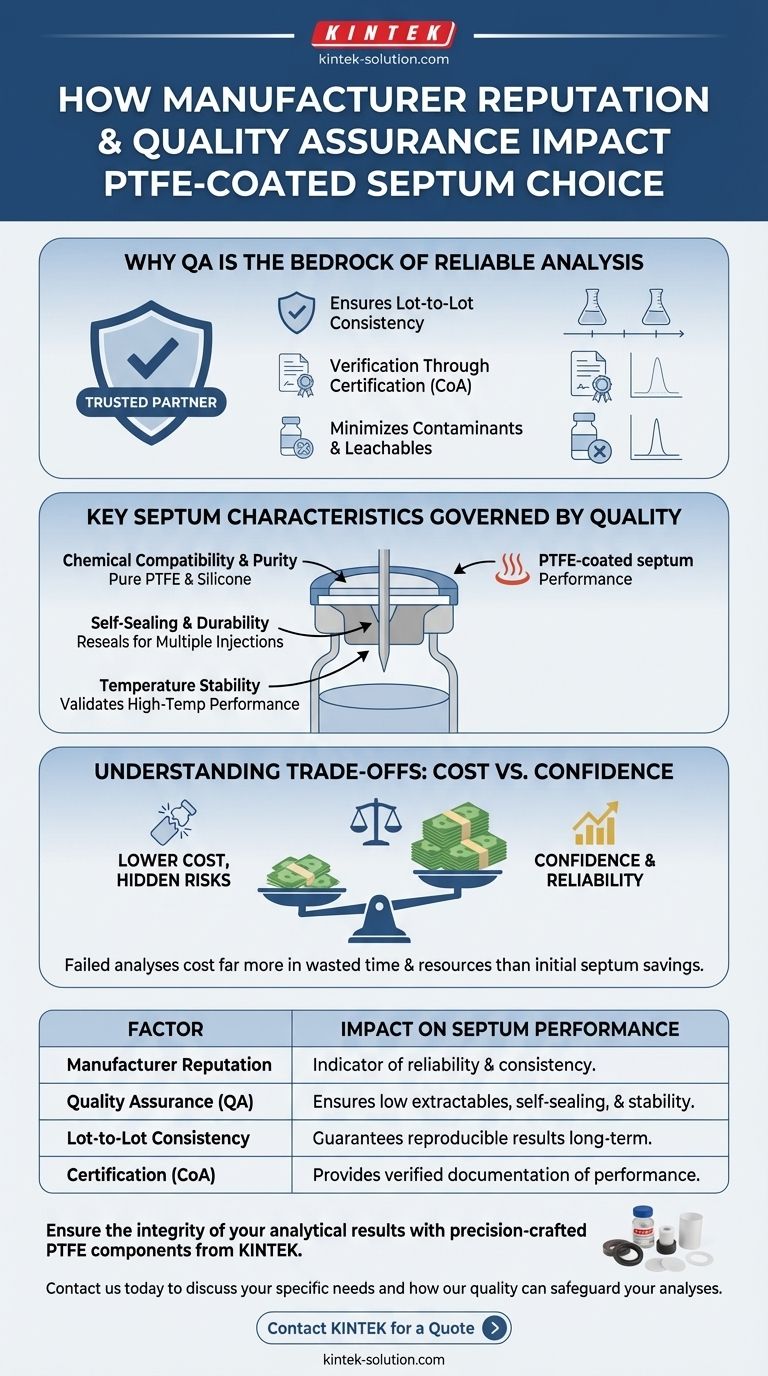

Why Manufacturer QA is the Bedrock of Reliable Analysis

The physical and chemical properties of a septum are a direct result of the manufacturing process. A commitment to quality is what separates a reliable component from a potential source of error.

Ensuring Lot-to-Lot Consistency

A reputable manufacturer guarantees that the septum you use today will perform identically to the one you use six months from now. This lot-to-lot consistency is fundamental for reproducible scientific results, especially in long-term studies or regulated environments.

Verification Through Certification

Top-tier suppliers often provide certificates of analysis or other documentation verifying the quality of their septa. This documentation confirms that the product has been tested and meets specific standards for factors like purity and durability.

Minimizing Contaminants and Leachables

Strict QA processes are essential for producing septa with minimal extractables and leachables. In ultra-sensitive analyses, such as gas chromatography (GC), contaminants from a low-quality septum can easily interfere with sample results and create ghost peaks.

Key Septum Characteristics Governed by Quality

A manufacturer's quality control directly impacts the critical performance characteristics you rely on during an analysis.

Chemical Compatibility and Purity

While PTFE is known for its broad chemical resistance, the overall integrity of the septum depends on the purity of the materials. A quality manufacturer ensures the PTFE coating and the underlying silicone are free from impurities that could react with your sample or solvent.

Self-Sealing and Durability

The ability of a septum to reseal properly after needle penetration is critical for preventing sample evaporation and maintaining pressure within the vial. High-quality manufacturing ensures the correct material hardness and thickness for reliable performance over multiple injections.

Temperature Stability

In applications like GC, the septum is exposed to high temperatures in the injection port. A reputable manufacturer validates the temperature stability of their products, ensuring the septum will not degrade, which could lead to contamination and sample loss.

Understanding the Trade-offs: Cost vs. Confidence

While it can be tempting to choose a lower-cost option, it's crucial to understand the potential hidden costs.

The Hidden Cost of a Failed Analysis

Choosing an unverified, low-cost septum introduces risk. A single failed run due to septum-related issues can cost far more in wasted solvents, samples, and operator time than the initial savings on the septa themselves.

Calculating the True Value

The value of a septum from a reputable manufacturer lies in its reliability. It removes a potential variable from your troubleshooting process and provides the confidence needed to trust your analytical results.

Making the Right Choice for Your Application

Your specific analytical needs should guide your final selection.

- If your primary focus is trace analysis, regulated testing, or mass spectrometry: Always select a premium septum from a top-tier manufacturer with available certification to guarantee low extractables and absolute reliability.

- If your primary focus is high-throughput screening or routine quality control: A product from a well-known, reputable manufacturer offers the best balance of consistent performance and cost-effectiveness.

- If your primary focus is method development or academic research: Begin with a high-quality, certified septum to eliminate it as a potential variable while establishing your method.

Ultimately, investing in a quality septum from a trusted manufacturer is an investment in the integrity of your results.

Summary Table:

| Factor | Impact on Septum Performance |

|---|---|

| Manufacturer Reputation | Indicator of product reliability and consistency. |

| Quality Assurance (QA) | Ensures low extractables, proper self-sealing, and temperature stability. |

| Lot-to-Lot Consistency | Guarantees reproducible results for long-term studies. |

| Certification (e.g., CoA) | Provides verified documentation of purity and performance standards. |

Ensure the integrity of your analytical results with precision-crafted PTFE components from KINTEK.

As detailed above, the manufacturer's quality assurance is paramount for reliable septa. KINTEK prioritizes precision production and stringent QA protocols for all our PTFE components, including seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, offering custom fabrication from prototypes to high-volume orders.

By choosing KINTEK, you gain a trusted partner committed to delivering the lot-to-lot consistency and minimal contaminant levels your sensitive applications demand. Contact us today to discuss your specific needs and how our quality can safeguard your analyses.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining