At its core, the low friction property of Teflon (PTFE) sheets dramatically enhances machinery performance by allowing components to slide against each other with minimal resistance. This core benefit translates directly into reduced wear and tear, lower energy consumption, and a significant decrease in maintenance requirements for parts like bearings, gears, and conveyor belts.

The true value of Teflon's low friction isn't just about smooth movement; it's about transforming machinery into more efficient, reliable, and cost-effective systems by fundamentally reducing the forces that cause wear, heat, and energy loss.

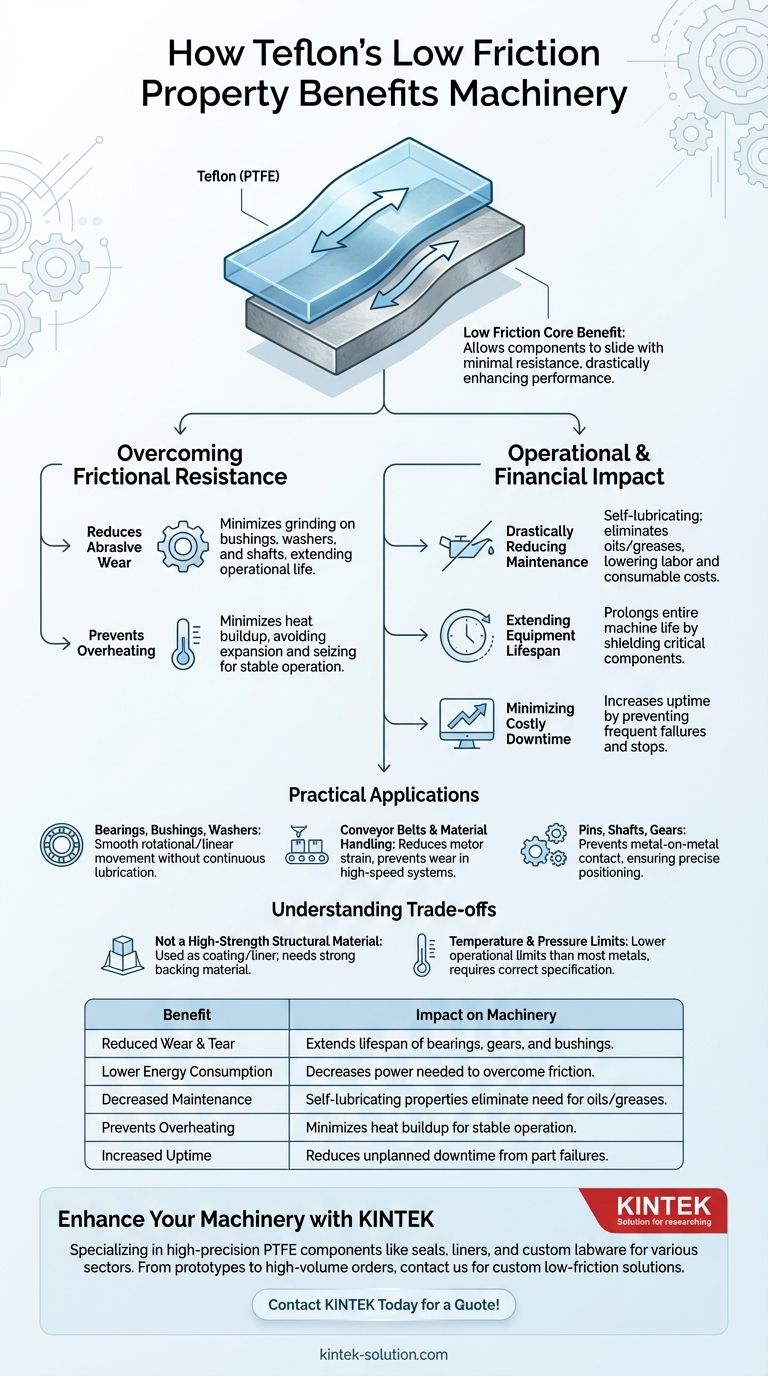

The Core Principle: Overcoming Frictional Resistance

Friction is the enemy of mechanical efficiency. It is the force that resists motion, generates heat, and wears down components over time. Teflon's unique molecular structure gives it one of the lowest coefficients of friction of any solid material, directly countering these destructive forces.

How Teflon Minimizes Wear and Tear

When two surfaces slide against each other, friction slowly grinds them down. Teflon acts as a protective, slippery barrier between these moving parts.

This reduces abrasive wear on critical components like bushings, washers, and shafts, allowing them to operate for much longer before needing replacement.

Preventing Overheating and Seizing

The energy lost to friction is converted directly into heat. In high-speed machinery, this heat can build up, causing parts to expand, deform, or even seize completely.

By minimizing frictional resistance, Teflon prevents dangerous heat accumulation, ensuring smoother and more stable operation.

The Operational and Financial Impact

The physical benefits of low friction create a powerful ripple effect, leading to significant operational and financial advantages. Choosing Teflon is often a strategic decision to improve the bottom line.

Drastically Reducing Maintenance Needs

Many mechanical systems require constant lubrication with oils and greases to manage friction. Teflon is self-lubricating, eliminating the need for these external lubricants.

This results in a cleaner operating environment and a "maintenance-free" solution that lowers labor costs and the expense of consumables.

Extending Equipment Lifespan

By shielding components from the constant grind of friction, Teflon prolongs the functional life of the entire machine.

Less wear means fewer part failures, which in turn means the equipment remains productive for a longer period, maximizing the return on a significant capital investment.

Minimizing Costly Downtime

The combined effects of reduced wear and lower maintenance directly lead to increased uptime.

When machinery runs reliably without frequent stops for lubrication or part replacement, productivity increases, and the costly impact of unplanned downtime is avoided.

Practical Applications Across Machinery

Teflon's versatility allows its low-friction benefits to be applied to a wide range of components across countless industries.

Bearings, Bushings, and Washers

These are classic applications where Teflon allows rotational or linear movement with minimal resistance. Teflon bushings in motors, pumps, and gears enable smooth operation without continuous lubrication.

Conveyor Belts and Material Handling

In continuous or high-speed material handling, Teflon surfaces allow products to slide easily, reducing the strain on drive motors and preventing wear on the belt itself.

Pins, Shafts, and Gears

Coating guide pins or using Teflon inserts in gear systems prevents the metal-on-metal contact that leads to premature failure, ensuring parts maintain their precise positioning and function.

Understanding the Trade-offs

While its low friction is a powerful advantage, Teflon is not a universal solution. Understanding its limitations is key to using it effectively.

Not a High-Strength Structural Material

Teflon is typically used as a coating, liner, or insert rather than a primary structural component. It provides the surface property, while a stronger material like steel provides the load-bearing strength.

Temperature and Pressure Limits

Although known for being heat-resistant, PTFE has operational temperature and pressure limits that are lower than most metals. It must be specified correctly for the intended environment to avoid degradation.

Making the Right Choice for Your Goal

Applying Teflon is about matching its unique properties to a specific operational need.

- If your primary focus is reliability and uptime: Teflon is a superb choice for reducing critical failure points by minimizing wear and eliminating the need for manual lubrication.

- If your primary focus is long-term cost reduction: The savings from decreased maintenance, fewer replacement parts, and lower energy consumption make Teflon a strong financial decision.

- If your primary focus is performance in clean environments: Teflon is ideal as it requires no messy external oils or greases that can contaminate products or processes.

Ultimately, integrating Teflon into machinery design is a direct strategy for creating more robust, efficient, and economical systems.

Summary Table:

| Benefit | Impact on Machinery |

|---|---|

| Reduced Wear & Tear | Extends lifespan of bearings, gears, and bushings. |

| Lower Energy Consumption | Decreases power needed to overcome friction. |

| Decreased Maintenance | Self-lubricating properties eliminate need for oils/greases. |

| Prevents Overheating | Minimizes heat buildup from friction for stable operation. |

| Increased Uptime | Reduces unplanned downtime from part failures. |

Ready to enhance your machinery's performance and profitability?

KINTEK specializes in manufacturing high-precision PTFE components like seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact low-friction solution to reduce wear, cut energy costs, and minimize maintenance.

Contact KINTEK today to discuss your application and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability