At its core, Teflon (PTFE) gland fillers reduce maintenance by creating a highly durable and chemically inert seal that simply lasts longer. Because the material resists both chemical degradation and physical wear, it does not need to be adjusted or replaced nearly as often as conventional packing materials, directly lowering labor costs and equipment downtime.

The true value of Teflon fillers is not just their long life, but the operational predictability they provide. By resisting the primary causes of seal failure—chemical attack and friction—they transform maintenance from a frequent, reactive task into a rare, planned event.

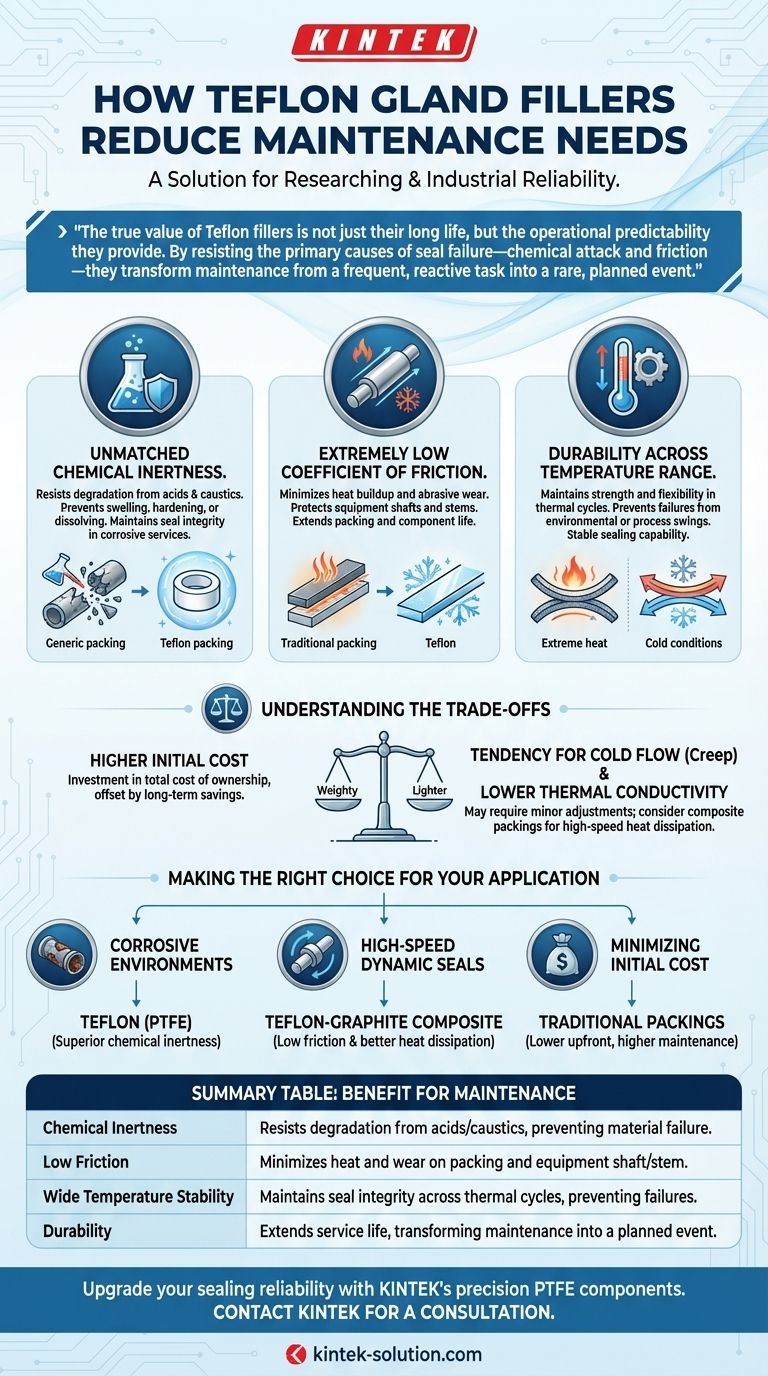

How Teflon Properties Translate to Reduced Maintenance

To understand the impact on maintenance, we must first look at the fundamental properties of Polytetrafluoroethylene (PTFE), the polymer commonly known as Teflon. These characteristics directly counter the most common reasons a gland seal fails.

Unmatched Chemical Inertness

A primary failure mode for gland packing is chemical degradation. The sealed fluid attacks the packing material, causing it to swell, harden, or dissolve over time.

Teflon is exceptionally non-reactive. It is virtually immune to attack from the vast majority of industrial chemicals, acids, and caustic solutions.

This inertness means the packing material maintains its integrity and sealing capability for extended periods, even in highly corrosive services like those found in acid-impregnated equipment.

Extremely Low Coefficient of Friction

Friction is the enemy of any dynamic seal. It generates heat, which can bake and harden the packing, and it physically wears away both the packing and the equipment shaft or stem.

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This "slipperiness" minimizes heat buildup and abrasive wear. The result is a longer life for the packing and, critically, less damage to expensive equipment components like pump shafts.

Durability Across a Wide Temperature Range

Seal materials must remain stable under operational conditions. Many materials become brittle at low temperatures or soften and extrude at high temperatures.

Teflon maintains its strength and flexibility across a broad temperature range, ensuring a reliable seal in systems with thermal cycles. This stability prevents failures caused by environmental or process temperature swings.

Understanding the Trade-offs

While highly effective, Teflon is not a universal solution. An objective assessment requires understanding its limitations.

Tendency for Cold Flow (Creep)

Under constant pressure, Teflon can exhibit "cold flow," a tendency to slowly deform or extrude over time.

This may require periodic, minor adjustments to the gland follower to maintain the proper compression on the packing. However, this adjustment is far less intensive than a full replacement.

Lower Thermal Conductivity

While its low friction minimizes heat generation, Teflon does not dissipate heat as well as materials like graphite.

In very high-speed, high-pressure pump applications, pure Teflon packing might struggle to shed the heat that is generated. Composite packings that blend Teflon with graphite are often used to mitigate this.

Higher Initial Cost

Teflon gland fillers typically have a higher upfront purchase price compared to traditional materials like flax or synthetic fibers.

The decision to use Teflon is an investment in total cost of ownership. The higher initial cost is offset by significant savings from reduced downtime, lower labor requirements, and fewer material purchases over the equipment's lifecycle.

Making the Right Choice for Your Application

Selecting the correct gland filler depends entirely on your system's operational demands and strategic goals.

- If your primary focus is reliability in corrosive environments: Teflon is the superior choice due to its unmatched chemical inertness, which prevents material degradation.

- If your primary focus is managing high-speed dynamic seals: Consider a Teflon-graphite composite packing to gain the benefits of low friction while improving heat dissipation.

- If your primary focus is minimizing initial purchase cost: Traditional packings are cheaper upfront, but you must accept and budget for the significantly higher frequency of maintenance and risk of unplanned downtime.

Ultimately, choosing the right packing material is a strategic decision that directly impacts your operational reliability and long-term profitability.

Summary Table:

| Property | Benefit for Maintenance |

|---|---|

| Chemical Inertness | Resists degradation from acids/caustics, preventing material failure. |

| Low Friction | Minimizes heat and wear on packing and equipment shaft/stem. |

| Wide Temperature Stability | Maintains seal integrity across thermal cycles, preventing failures. |

| Durability | Extends service life, transforming maintenance into a planned event. |

Upgrade your sealing reliability with KINTEK's precision PTFE components.

Tired of frequent, unplanned downtime and high maintenance costs from seal failures? KINTEK specializes in manufacturing high-performance PTFE gland fillers, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our components are engineered for superior chemical resistance, low friction, and long-term durability—directly reducing your maintenance frequency, labor costs, and equipment wear.

Whether you need a standard solution or a custom fabrication from prototype to high-volume orders, we prioritize precision to ensure your operations run smoothly and predictably.

Contact KINTEK today for a consultation and see how our PTFE solutions can enhance your operational efficiency and profitability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications