Fundamentally, the high-temperature resistance of a PTFE processing machine is what makes reliable production possible. This capability allows the equipment to operate consistently at the extreme temperatures required to melt and form PTFE resin without degrading its own components, which is essential for ensuring both machine longevity and the quality of the final product.

The thermal stability of a PTFE processing machine is not merely a feature—it is a core requirement dictated by the unique high-melting-point nature of Polytetrafluoroethylene (PTFE) itself. This resistance directly translates to operational reliability, consistent output, and process safety.

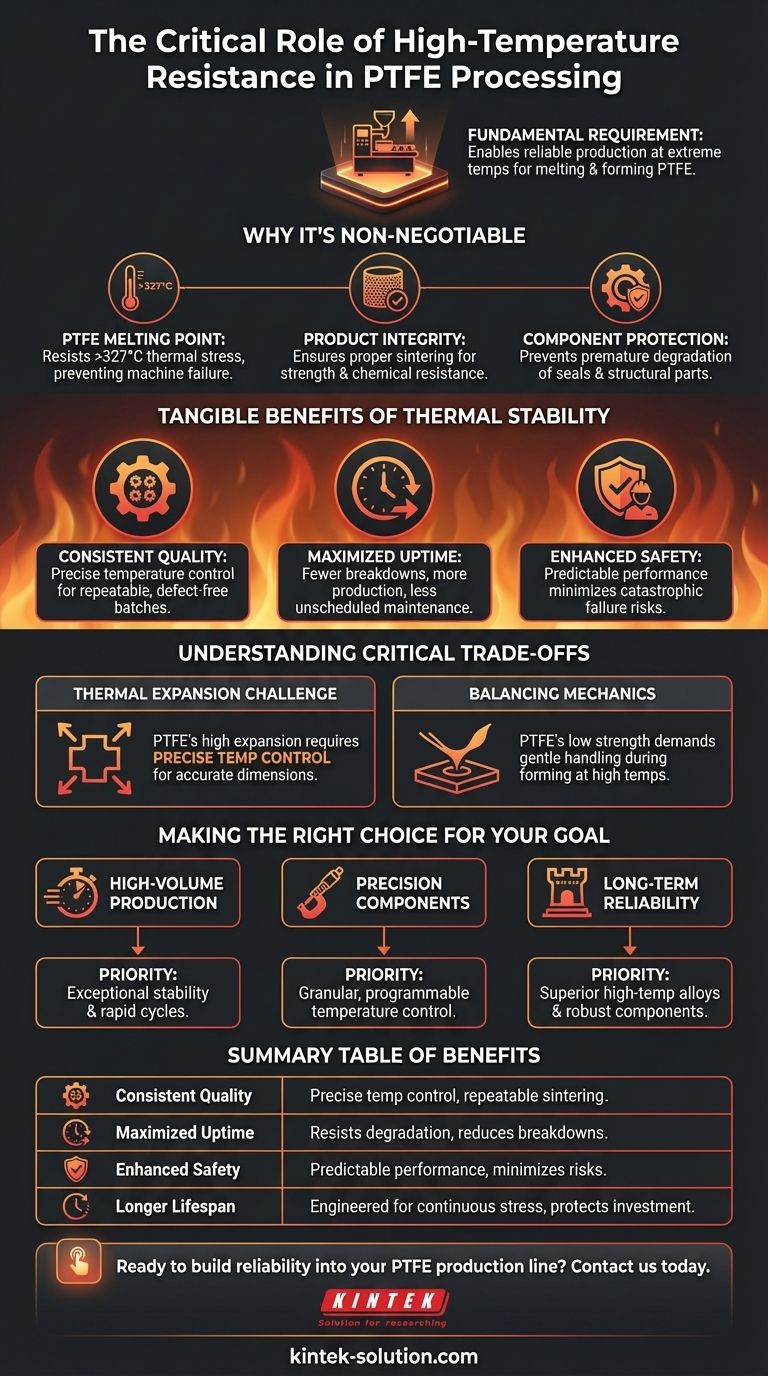

Why High Temperatures Are Non-Negotiable

To understand the benefit of a heat-resistant machine, we must first understand the material it is designed to process. PTFE is not a typical plastic, and its unique properties place extreme demands on any equipment that handles it.

The Demands of PTFE's Melting Point

PTFE has a very high melting point, typically around 327°C (621°F). Processing, particularly sintering, often requires temperatures exceeding this.

A standard machine built with conventional metals and components would quickly fail, warp, or degrade under such continuous thermal stress. The machine's resistance ensures it can reach and sustain these critical processing temperatures.

Ensuring Final Product Integrity

The final mechanical and chemical properties of a PTFE part are directly linked to the precision of the heating and cooling cycle.

If a machine cannot maintain a stable, high temperature, the PTFE may not be properly sintered. This results in parts with poor mechanical strength, porosity, and diminished chemical resistance.

Protecting Machine Components

Continuous operation at hundreds of degrees Celsius places enormous stress on every part of a machine, from structural frames to seals and actuators.

PTFE processing machines use specialized materials and designs that resist thermal degradation. This prevents premature equipment failure, reduces maintenance, and ensures a longer operational lifespan. As a comparison, common elastomers like NBR or EPDM fail at temperatures below 150°C, making them unsuitable for these environments.

The Tangible Benefits of Thermal Stability

A machine that can reliably handle the heat of PTFE processing delivers several clear operational advantages that directly impact the bottom line.

Consistent and Repeatable Quality

A thermally stable machine provides precise temperature control. This consistency is the key to producing identical parts batch after batch, minimizing defects and waste.

Maximized Operational Uptime

Equipment that is engineered to withstand its operating environment is inherently more reliable. High-temperature resistance means fewer breakdowns caused by component failure, leading to more production time and less unscheduled maintenance.

A Safer Operating Environment

Predictable machine performance is a cornerstone of workplace safety. A machine that effectively manages extreme heat is less prone to catastrophic failures, protecting both the operator and the investment.

Understanding the Critical Trade-offs

While high-temperature resistance is essential, it is not the only factor to consider. The properties of PTFE itself introduce complexities that must be managed.

The Challenge of Thermal Expansion

PTFE has a very high coefficient of thermal expansion. Even if the machine can withstand the heat, the material itself will change size significantly as it heats and cools.

This makes precise temperature control—not just resistance—absolutely critical. The machine must manage the cooling phase carefully to produce parts with accurate final dimensions.

Balancing Heat with Mechanical Properties

PTFE has relatively low mechanical strength, which is even more pronounced at high processing temperatures.

The machine's design must account for this. It needs to handle the material gently during the forming process to avoid defects, even while operating under extreme thermal conditions.

Making the Right Choice for Your Goal

Selecting the right equipment requires matching its capabilities to your primary production objective.

- If your primary focus is high-volume production: Prioritize machines with exceptional thermal stability and rapid, repeatable heating and cooling cycles to maximize throughput and consistency.

- If your primary focus is precision components: Seek out machines that offer not just high-temperature resistance but also granular, programmable temperature control to precisely manage thermal expansion.

- If your primary focus is long-term reliability: Invest in machines built with superior high-temperature alloys and robust components to ensure durability and minimize lifetime maintenance costs.

Ultimately, choosing a machine with the correct thermal capabilities is the foundation for successful and efficient PTFE processing.

Summary Table:

| Benefit | Impact on Operation |

|---|---|

| Consistent Quality | Precise temperature control ensures repeatable sintering and part integrity. |

| Maximized Uptime | Robust components resist thermal degradation, reducing breakdowns and maintenance. |

| Enhanced Safety | Predictable performance minimizes risks of catastrophic failure at extreme temperatures. |

| Longer Machine Lifespan | Engineered to withstand continuous stress, protecting your capital investment. |

Ready to build reliability into your PTFE production line?

At KINTEK, we specialize in manufacturing high-performance PTFE components and understand the critical need for thermal stability. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your processing equipment is equipped to handle the extreme demands of PTFE.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide the precision and durability your operations require. Contact us today to discuss how our components can enhance your machine's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments