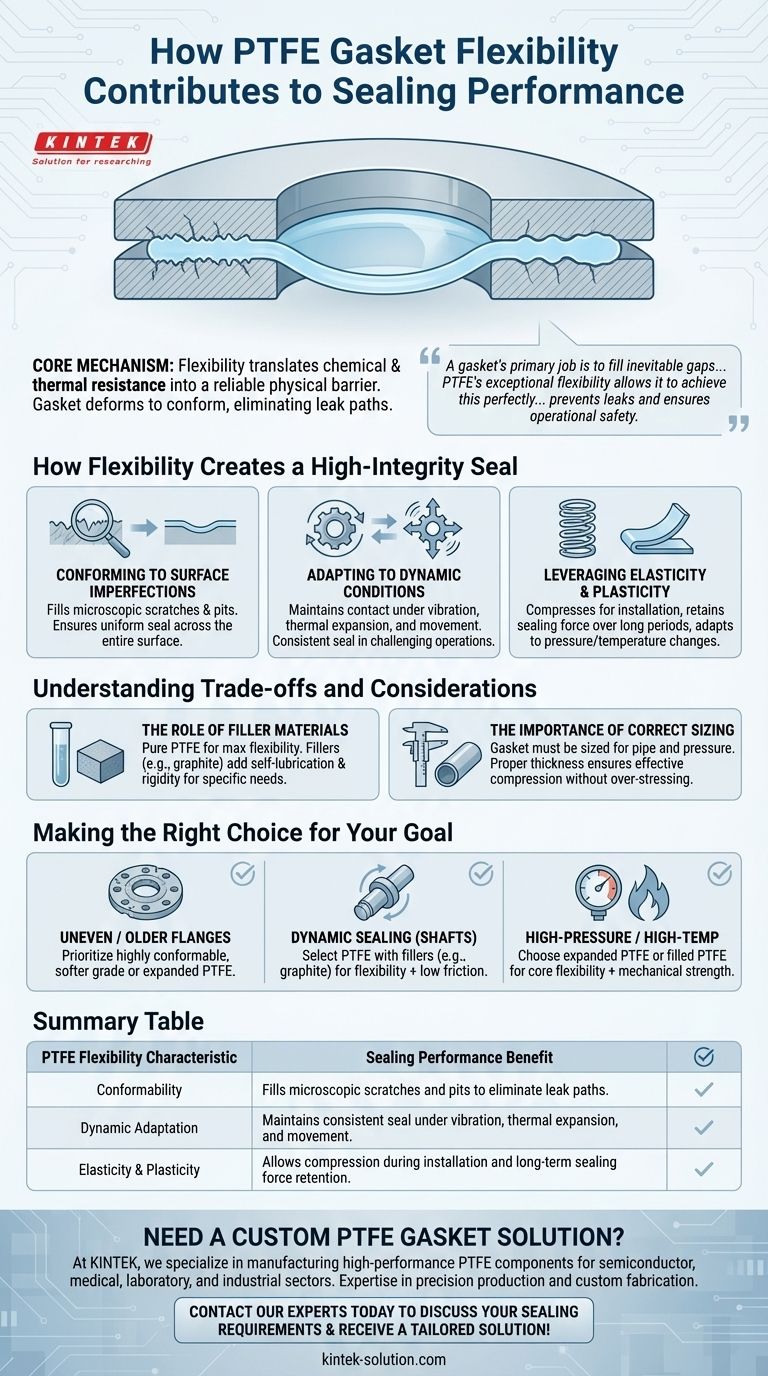

At its core, the flexibility of a PTFE gasket is the mechanism that translates its chemical and thermal resistance into a reliable physical barrier. This inherent pliability allows the gasket material to deform and flow under pressure, perfectly conforming to the microscopic imperfections found on mating surfaces. This creates an exceptionally tight and secure seal where a more rigid material would create leak paths.

A gasket's primary job is to fill the inevitable, microscopic gaps between two rigid surfaces. PTFE's exceptional flexibility and conformability allow it to achieve this perfectly, creating a continuous, high-integrity seal that prevents leaks and ensures operational safety.

How Flexibility Creates a High-Integrity Seal

A gasket's performance is defined by its ability to create and maintain a barrier. The unique physical properties of Polytetrafluoroethylene (PTFE) make its flexibility a key component of its sealing power.

Conforming to Surface Imperfections

No industrial flange or mating surface is perfectly flat. They have microscopic scratches, pits, and waviness from the manufacturing process or from operational wear.

PTFE's flexibility allows it to be compressed into these irregularities. This conformability ensures that the gasket material fills every potential leak path, creating a complete and uniform seal across the entire surface.

Adapting to Dynamic Conditions

Many applications are not static. Equipment vibrates, shafts rotate, and components shift due to thermal expansion and contraction.

PTFE's ability to remain pliable allows it to maintain constant contact with the sealing surface even under these dynamic loads. It can adapt to the movement of a rotating shaft or subtle changes in a flange gap, ensuring a consistent seal under challenging operating conditions.

Leveraging Elasticity and Plasticity

Expanded PTFE (ePTFE) in particular exhibits excellent elasticity (the ability to return to its original shape) and plasticity (the ability to deform permanently without breaking).

This combination allows the gasket to be compressed during installation to form a seal, and then to maintain that sealing force over long periods, adapting to changes in pressure and temperature without failing.

Understanding the Trade-offs and Considerations

While flexibility is a primary benefit, it must be managed correctly to ensure optimal performance. The type of PTFE and its application are critical factors.

The Role of Filler Materials

Pure PTFE provides maximum flexibility and chemical resistance. However, for applications requiring greater mechanical strength or specific properties, fillers are added.

Fillers like graphite can add self-lubricating properties and rigidity, which is ideal for components like compressor rings. This modifies the base flexibility to suit a specific mechanical need.

The Importance of Correct Sizing

PTFE's flexibility is not a substitute for proper engineering. Gaskets must be sized correctly for the specific pipe size and pressure rating.

Choosing the right thickness and form factor, whether a custom-fabricated shape or a compressed sheet, ensures the material can be properly compressed to activate its sealing properties without being over-stressed.

Making the Right Choice for Your Goal

Selecting the correct gasket involves matching the material's properties to the application's demands.

- If your primary focus is sealing uneven or older flanges: Prioritize a highly conformable, softer grade or an expanded PTFE gasket that can easily flow into surface imperfections.

- If your primary focus is dynamic sealing on shafts or moving parts: Select a PTFE variant with fillers like graphite that combines flexibility with a low coefficient of friction for durability.

- If your primary focus is high-pressure or high-temperature stability: Choose an expanded PTFE or a filled PTFE sheet that leverages the material's core flexibility while adding the necessary mechanical strength to resist extrusion.

Ultimately, leveraging PTFE's flexibility is about matching the right degree of conformability to the specific mechanical and chemical demands of your system.

Summary Table:

| PTFE Flexibility Characteristic | Sealing Performance Benefit |

|---|---|

| Conformability | Fills microscopic scratches and pits on mating surfaces to eliminate leak paths. |

| Dynamic Adaptation | Maintains a consistent seal under vibration, thermal expansion, and movement. |

| Elasticity & Plasticity | Allows for compression during installation and long-term sealing force retention. |

Need a custom PTFE gasket solution for your application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a gasket that perfectly balances flexibility, strength, and chemical resistance for your specific needs.

Contact our experts today to discuss your sealing requirements and receive a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials