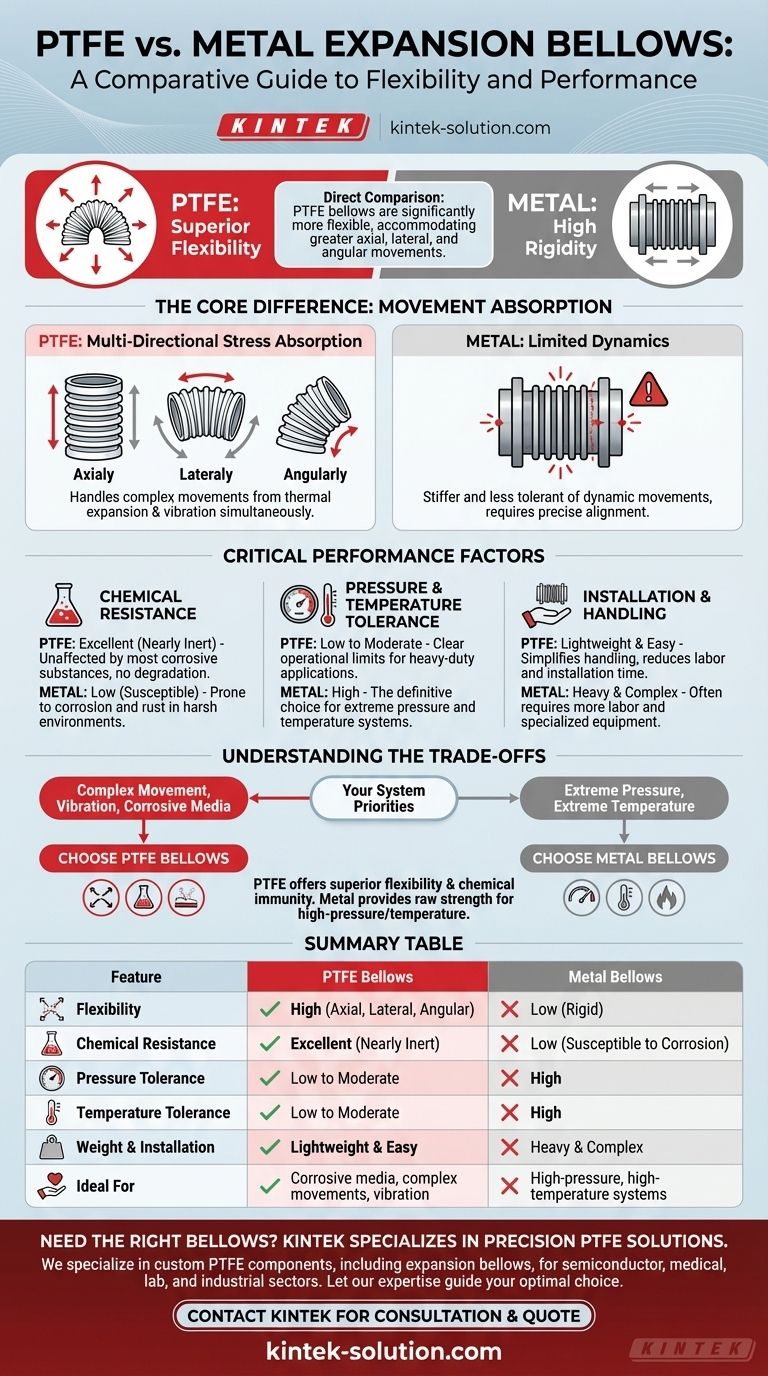

In a direct comparison, PTFE expansion bellows are significantly more flexible than their metal counterparts. This higher flexibility allows them to accommodate greater axial, lateral, and angular movements within a piping system without compromising structural integrity. Metal bellows, while very strong, are inherently stiffer and less tolerant of dynamic pipe movements.

The core decision between PTFE and metal bellows hinges on a trade-off: PTFE provides superior flexibility and chemical immunity for complex, corrosive environments, while metal offers the raw strength needed for high-pressure and high-temperature applications.

The Core Difference: Flexibility and Movement

The primary advantage of PTFE lies in its material properties, which allow it to absorb multi-directional stress far more effectively than rigid metal.

Superior Movement Absorption in PTFE

PTFE expansion bellows are engineered to handle a wide range of motion. Their versatility allows them to compensate for various types of pipe displacement simultaneously.

This includes axial (compression/extension), lateral (sideways), and angular movements caused by factors like thermal expansion or machinery vibrations.

The Rigidity of Metal Bellows

Metal bellows, by contrast, are much more rigid. Their strength is also their limitation in certain applications.

While they are exceptionally durable, they are less forgiving of dynamic and complex pipe movements, which can create stress points in the system if not perfectly aligned.

Beyond Flexibility: Critical Performance Factors

Flexibility is only one part of the equation. The operational environment, specifically the media being transported and the installation process, are equally critical factors.

Unmatched Chemical Resistance

PTFE is nearly chemically inert, making it unaffected by the vast majority of corrosive substances.

Unlike metal, which is susceptible to corrosion and rust in harsh environments like chemical plants or saline water facilities, PTFE bellows do not degrade.

High-Pressure and Temperature Tolerance

This is the domain where metal bellows excel. Their robust construction makes them the definitive choice for systems operating under extreme pressure or temperature.

PTFE has clear operational limits for temperature and pressure that make it unsuitable for these heavy-duty applications.

Installation and Handling

PTFE bellows are significantly lighter and easier to install than their metal counterparts. This lightweight nature simplifies handling and can reduce installation time and labor costs.

Heavy metal bellows often require more labor and specialized equipment to position and install correctly.

Understanding the Trade-offs

Choosing the right expansion bellow requires an objective assessment of each material's inherent limitations. There is no single "best" option for every scenario.

When PTFE is Not the Answer

The primary trade-off for PTFE's flexibility and chemical resistance is its lower tolerance for extreme temperatures and high pressures. In these environments, metal is the only viable solution.

The Vulnerability of Metal

The strength of metal comes at a cost. Its susceptibility to chemical corrosion makes it a poor choice for transporting aggressive media, and its rigidity can be a liability in systems with significant vibration or misalignment.

Making the Right Choice for Your System

Your selection should be guided by the primary demands of your specific application. Analyze your system's operational priorities to make a clear, effective decision.

- If your primary focus is accommodating complex pipe movement or vibration: PTFE is the superior choice due to its inherent flexibility across multiple axes.

- If your primary focus is handling highly corrosive media: The unmatched chemical inertness of PTFE makes it the most reliable and long-lasting option.

- If your primary focus is operating under extreme temperature or pressure: Metal bellows are purpose-built for these demanding conditions and are the only suitable choice.

- If your primary focus is simplifying installation and reducing labor: The lightweight and easy-to-handle nature of PTFE bellows provides a distinct advantage.

Ultimately, selecting the right bellow requires a clear understanding of your system's unique operational demands.

Summary Table:

| Feature | PTFE Bellows | Metal Bellows |

|---|---|---|

| Flexibility | High (Axial, lateral, angular) | Low (Rigid) |

| Chemical Resistance | Excellent (Nearly inert) | Low (Susceptible to corrosion) |

| Pressure Tolerance | Low to Moderate | High |

| Temperature Tolerance | Low to Moderate | High |

| Weight & Installation | Lightweight & Easy | Heavy & Complex |

| Ideal For | Corrosive media, complex movements, vibration | High-pressure, high-temperature systems |

Need the Right Expansion Bellows for Your Application?

Choosing between PTFE and metal is critical for your system's performance and longevity. KINTEK specializes in manufacturing high-precision, custom PTFE components—including seals, liners, labware, and PTFE expansion bellows—for the semiconductor, medical, laboratory, and industrial sectors.

We understand the trade-offs and can help you select or fabricate the ideal solution, from prototypes to high-volume orders, ensuring it meets your exact requirements for flexibility, chemical resistance, and durability.

Let our expertise guide you to the optimal choice. Contact KINTEB today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications