At its core, the chemical resistance of PTFE O-rings provides unparalleled reliability in harsh industrial settings. This near-universal chemical inertness prevents the O-ring from degrading when exposed to aggressive acids, solvents, and bases. For industrial operations, this means a more durable and predictable seal, directly preventing dangerous leaks, costly downtime, and product contamination.

The exceptional chemical resistance of Polytetrafluoroethylene (PTFE) is not just a material property; it is a foundational guarantee of operational integrity. This stability ensures the seal will not swell, harden, or dissolve, maintaining its function in environments where nearly any other material would fail.

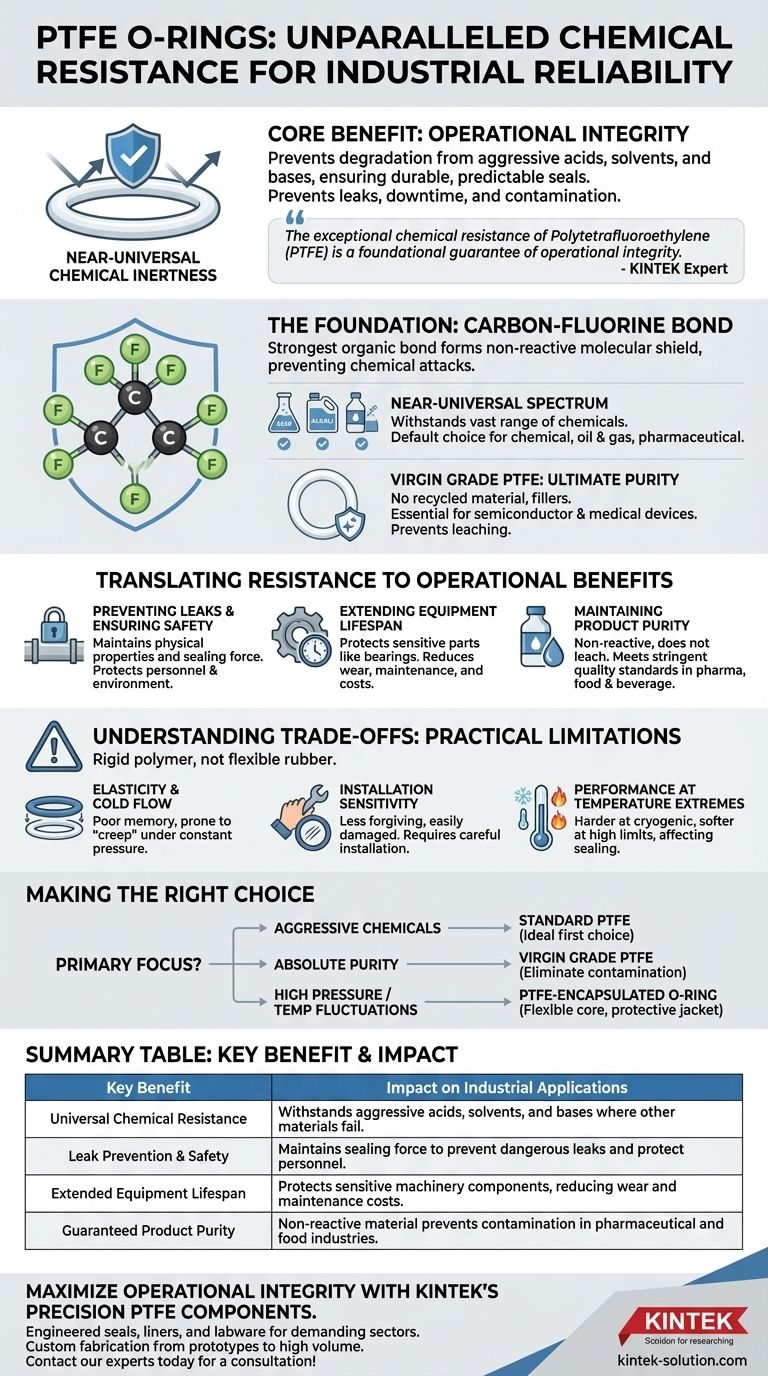

The Foundation of PTFE's Chemical Resistance

To understand the benefits, we must first understand the source of this remarkable stability. PTFE's performance is rooted in its unique molecular structure, which sets it apart from conventional elastomers.

What Makes PTFE Chemically Inert?

PTFE consists of a long chain of carbon atoms completely shielded by fluorine atoms. The carbon-fluorine bond is one of the strongest in organic chemistry.

This powerful bond creates a non-reactive, stable molecular shield. It effectively prevents chemicals from attacking the polymer chain, making the material inert to nearly all industrial substances.

A Near-Universal Spectrum of Resistance

This molecular stability gives PTFE O-rings the ability to withstand a vast range of chemicals without deteriorating.

This includes aggressive acids, alkalis, solvents, and corrosive agents. This is why PTFE is the default choice for sealing applications in chemical manufacturing, oil and gas, and pharmaceutical production.

The Role of Purity: Virgin Grade PTFE

For the most critical applications, virgin PTFE is used. This grade contains no recycled material, processing aids, or fillers.

Its superior purity is essential in industries like semiconductor manufacturing and medical device production, where even trace amounts of leaching or contamination from the seal itself are unacceptable.

Translating Resistance into Operational Benefits

The chemical inertness of PTFE is not an abstract feature; it delivers tangible, critical advantages that enhance safety, efficiency, and product quality.

Preventing Leaks and Ensuring Safety

The primary function of any O-ring is to seal. When a seal is exposed to an incompatible chemical, it can swell, shrink, or become brittle, leading to failure.

PTFE's resistance ensures it maintains its physical properties and sealing force, preventing leaks of hazardous materials and protecting both personnel and the environment.

Extending Equipment Lifespan

A reliable seal does more than just contain a fluid; it protects the internal components of machinery.

By preventing corrosive media from reaching sensitive parts like bearings and electronics, PTFE O-rings reduce equipment wear and extend maintenance intervals. This directly lowers long-term operational costs.

Maintaining Product Purity

In industries like pharmaceuticals or food and beverage, the seal must not contaminate the product.

Because PTFE is so non-reactive, it does not leach chemicals or impurities into the process stream. This ensures the final product meets stringent quality and safety standards.

Understanding the Trade-offs

While its chemical resistance is nearly unmatched, PTFE is not a universal solution. As a trusted advisor, it is my responsibility to highlight its practical limitations. It is a rigid polymer, not a flexible elastomer like rubber.

The Challenge of Elasticity and Cold Flow

PTFE has very poor "memory" and is not as elastic as rubber O-rings. It can be prone to cold flow, or "creep," where the material slowly deforms over time under constant pressure. This can compromise the seal in high-pressure applications or those with frequent pressure cycles.

Installation Sensitivity

Because of their rigidity, PTFE O-rings are less forgiving during installation. They can be easily scratched or damaged if stretched improperly over threads, creating a potential leak path from the start. Careful installation is critical.

Performance at Temperature Extremes

PTFE operates across an exceptionally wide temperature range (typically -200°C to +260°C). However, it becomes much harder at cryogenic temperatures and much softer at its upper limit, which can affect sealing performance under pressure.

Making the Right Choice for Your Application

Selecting the right seal requires balancing chemical compatibility with the mechanical demands of the system.

- If your primary focus is sealing against the most aggressive chemicals: Standard PTFE is an ideal first choice due to its near-universal resistance.

- If your primary focus is ensuring absolute product purity: Choose Virgin Grade PTFE to eliminate any risk of contamination from fillers or additives.

- If your application involves high pressure or significant temperature fluctuations: Consider a PTFE-encapsulated O-ring, which combines a flexible elastomer core with a protective PTFE jacket to get the best of both worlds.

Ultimately, choosing a PTFE O-ring is a strategic decision to prioritize chemical stability and long-term operational integrity above all else.

Summary Table:

| Key Benefit | Impact on Industrial Applications |

|---|---|

| Universal Chemical Resistance | Withstands aggressive acids, solvents, and bases where other materials fail. |

| Leak Prevention & Safety | Maintains sealing force to prevent dangerous leaks and protect personnel. |

| Extended Equipment Lifespan | Protects sensitive machinery components, reducing wear and maintenance costs. |

| Guaranteed Product Purity | Non-reactive material prevents contamination in pharmaceutical and food industries. |

Maximize your operational integrity with KINTEK's precision PTFE components.

Our PTFE seals, liners, and labware are engineered for the most demanding environments in the semiconductor, medical, and industrial sectors. Whether you need standard or ultra-pure virgin PTFE for critical applications, KINTEK delivers custom fabrication from prototypes to high-volume orders with a focus on precision and reliability.

Let us help you solve your toughest sealing challenges. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability