The fundamental benefit of PTFE's chemical resistance is its ability to provide exceptional durability and operational integrity in highly corrosive environments. Where other materials would quickly degrade, swell, or fail, PTFE bushes remain stable and functional, ensuring longer component life, reducing costly downtime, and preventing catastrophic leaks.

The core challenge in many industrial applications is finding a material that can survive prolonged contact with aggressive chemicals. PTFE's value comes from its near-total chemical inertness, which allows it to function reliably in environments that would destroy most other plastics and even some metals.

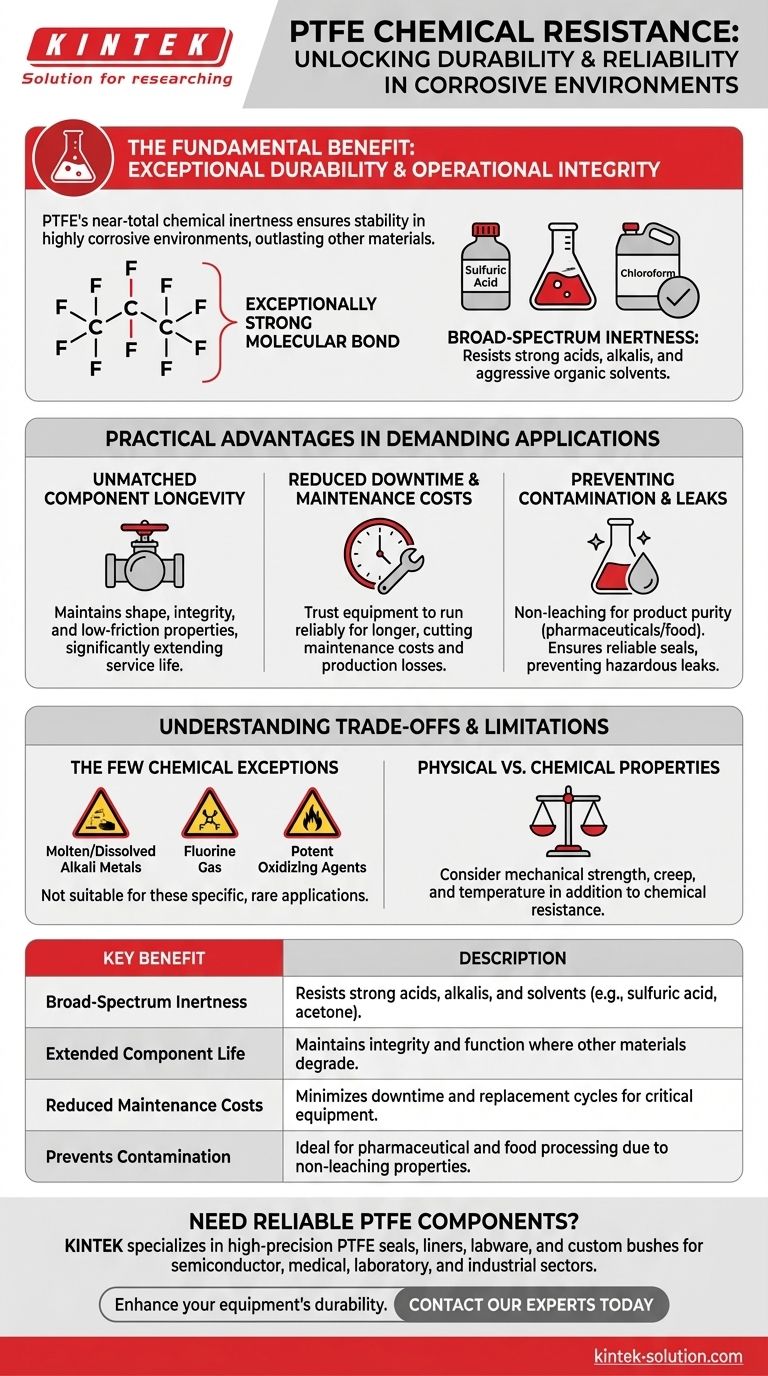

The Foundation of PTFE's Chemical Resistance

Polytetrafluoroethylene (PTFE) is not merely resistant to chemicals; for most practical purposes, it is chemically inert. This property is not accidental but is a direct result of its unique molecular structure.

An Exceptionally Strong Molecular Bond

The basis for PTFE's stability is the powerful bond between its carbon and fluorine atoms. This is one of the strongest single bonds in organic chemistry, making the molecule incredibly difficult for chemical reactants to break apart.

Broad-Spectrum Inertness

This molecular stability makes PTFE resistant to a vast range of substances. It remains unaffected by prolonged exposure to most strong acids, alkalis, and aggressive organic solvents.

This includes common industrial chemicals such as sulfuric acid, hydrochloric acid, acetone, and chloroform, which can be highly destructive to lesser materials.

Practical Advantages in Demanding Applications

This extreme resistance translates directly into tangible operational benefits across multiple industries, particularly chemical processing, oil and gas, and pharmaceuticals.

Unmatched Component Longevity

In a chemical pump, valve, or pipeline, a bush made from a standard plastic might swell, soften, or dissolve when exposed to aggressive media. A PTFE bush, however, will maintain its shape, integrity, and low-friction properties, leading to a significantly longer service life.

Reduced Downtime and Maintenance Costs

Component failure due to chemical attack leads to expensive downtime and labor-intensive replacement cycles. By using PTFE bushes in critical points, operators can trust the equipment to run reliably for longer periods, drastically cutting maintenance costs and production losses.

Preventing Contamination and Leaks

Because PTFE is so inert, it does not leach substances into the media it contacts. This is critical in pharmaceutical and food processing applications where product purity is paramount. Its stability also ensures a reliable seal, preventing dangerous leaks of hazardous materials.

Understanding the Trade-offs and Limitations

While its chemical resistance is nearly universal, it is crucial to understand that PTFE is not completely invincible. An expert assessment requires acknowledging its specific, albeit rare, weaknesses.

The Few Chemical Exceptions

PTFE's legendary inertness has a few known exceptions. It can be attacked by a very specific class of highly reactive substances.

These include molten or dissolved alkali metals (like sodium), fluorine gas, and certain other extremely potent oxidizing agents. In these specific and rare applications, PTFE should not be used.

Physical vs. Chemical Properties

It is also important to separate chemical resistance from mechanical properties. While PTFE excels in corrosive environments, it has limitations regarding mechanical strength, creep (deformation under load), and temperature compared to some metals or engineered plastics. The selection of PTFE must consider both the chemical and the physical demands of the application.

Making the Right Choice for Your Goal

Your material selection must be guided by a clear understanding of your primary operational challenge.

- If your primary focus is reliability in aggressive chemical environments: PTFE is the default high-performance choice, ensuring long service life and preventing failures caused by corrosion or chemical attack.

- If your primary focus is managing high mechanical stress or extreme temperatures: You must verify that PTFE's physical properties meet your requirements, as these can be a limiting factor even if its chemical resistance is ideal.

- If you are handling highly specific reactive agents like molten alkali metals or fluorine gas: You must seek a specialized alternative, as this is one of the few environments where PTFE is not a suitable material.

By understanding both its unparalleled chemical stability and its specific limitations, you can deploy PTFE with confidence where it will deliver the most value.

Summary Table:

| Key Benefit | Description |

|---|---|

| Broad-Spectrum Inertness | Resists strong acids, alkalis, and solvents (e.g., sulfuric acid, acetone). |

| Extended Component Life | Maintains integrity and function where other materials degrade. |

| Reduced Maintenance Costs | Minimizes downtime and replacement cycles for critical equipment. |

| Prevents Contamination | Ideal for pharmaceutical and food processing due to non-leaching properties. |

Need reliable PTFE components for your corrosive applications?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, labware, and custom bushes—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a solution tailored to your specific chemical and operational challenges.

Enhance your equipment's durability and performance. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance