In a direct comparison, Teflon (PTFE) significantly outperforms rubber in high-temperature and low-friction environments. While rubber is valued for its flexibility, it degrades and can become sticky at elevated temperatures, whereas Teflon remains exceptionally smooth and stable.

The choice between Teflon and rubber is not about which is "better," but which is correct for the specific engineering challenge. Teflon is a high-performance specialty plastic for extreme conditions, while rubber is a versatile elastomer prized for its flexibility and sealing capabilities.

Defining the Materials

Understanding the fundamental nature of each material is the first step in selecting the right one for your needs. They belong to different classes of polymers with distinct inherent properties.

What is Teflon?

Teflon is the brand name for Polytetrafluoroethylene (PTFE), a fluoropolymer. Its molecular structure gives it unique properties.

It is best known for its extreme chemical inertness and one of the lowest coefficients of friction of any solid.

What is Rubber?

Rubber is an elastomer, a polymer characterized by its high elasticity. It can be natural or synthetic.

Its primary advantage is its ability to be deformed under stress and return to its original shape once the stress is removed.

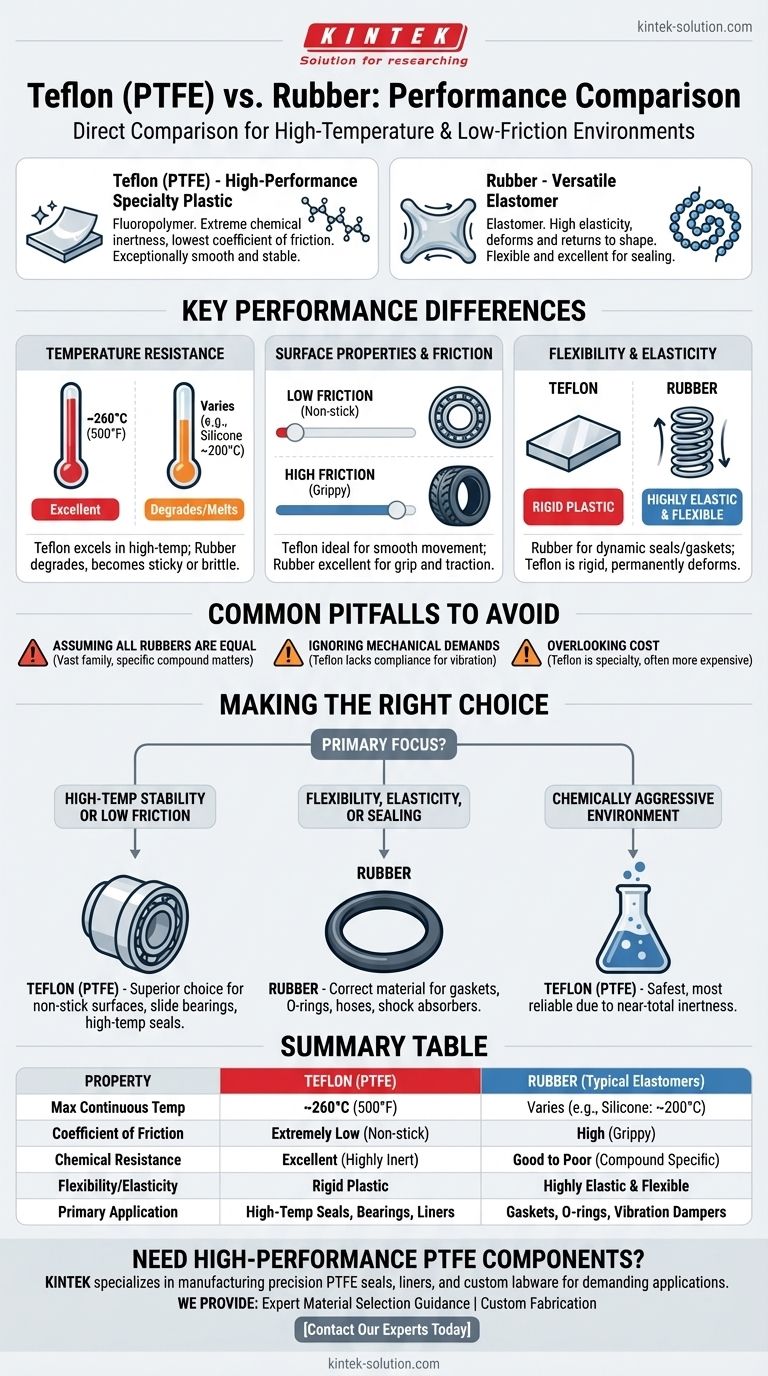

Key Performance Differences

The operational environment is the most critical factor when comparing these two materials. Their performance diverges significantly under conditions of heat, friction, and chemical exposure.

Temperature Resistance

Teflon excels in high-temperature applications, capable of withstanding continuous service temperatures far higher than most rubber compounds.

Rubber, by contrast, will degrade at these temperatures. It can become brittle when cold or sticky and soft when hot, losing its structural integrity.

Surface Properties and Friction

Teflon possesses an famously non-stick, low-friction surface. This makes it ideal for applications like bearings, seals, and non-stick coatings where smooth movement is critical.

Rubber typically has a high coefficient of friction. This property is advantageous for applications needing grip, such as tires or shoe soles, but is a disadvantage where parts must slide against each other.

Flexibility and Elasticity

This is rubber's defining strength. Its ability to stretch, compress, and bend repeatedly without damage makes it the clear choice for dynamic seals, gaskets, and vibration dampeners.

While Teflon is not brittle and can be formed into various shapes, it is a relatively rigid plastic. It does not possess the "memory" or elasticity of rubber and will deform permanently if stretched.

Common Pitfalls to Avoid

Choosing a material based on a single property without considering the complete system can lead to failure. It is crucial to evaluate the entire context of the application.

Assuming All Rubbers are Equal

The term "rubber" covers a vast family of materials (Nitrile, EPDM, Silicone, etc.), each with different temperature and chemical resistances. A generic comparison is a starting point, but specific compound selection is critical.

Ignoring Mechanical Demands

Teflon's rigidity makes it unsuitable for applications requiring significant compliance or vibration absorption. Using it where a flexible rubber is needed will result in leaks or mechanical failure.

Overlooking Cost

Teflon is a specialty material and is generally more expensive than common commodity rubber compounds. Its use must be justified by specific performance requirements that rubber cannot meet.

Making the Right Choice for Your Application

Your selection should be guided by the primary demand of your specific environment.

- If your primary focus is high-temperature stability or low friction: Teflon is the superior choice, ideal for non-stick surfaces, slide bearings, and high-temp seals.

- If your primary focus is flexibility, elasticity, or sealing: Rubber is the correct material, perfectly suited for gaskets, O-rings, hoses, and shock absorbers.

- If your primary focus is operating in a chemically aggressive environment: Teflon's near-total chemical inertness makes it the safest and most reliable option.

Ultimately, selecting the right material is about precisely matching its inherent properties to the challenges of your application.

Summary Table:

| Property | Teflon (PTFE) | Rubber (Typical Elastomers) |

|---|---|---|

| Max Continuous Temp | ~260°C (500°F) | Varies (e.g., Silicone: ~200°C) |

| Coefficient of Friction | Extremely Low (Non-stick) | High (Grippy) |

| Chemical Resistance | Excellent (Highly Inert) | Good to Poor (Compound Specific) |

| Flexibility/Elasticity | Rigid Plastic | Highly Elastic & Flexible |

| Primary Application | High-Temp Seals, Bearings, Liners | Gaskets, O-rings, Vibration Dampers |

Need High-Performance PTFE Components for Demanding Applications?

Choosing between Teflon and rubber is critical for the success and safety of your project. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for industries where material performance is non-negotiable.

We provide:

- Expert Material Selection Guidance to ensure your component operates flawlessly in extreme temperatures and corrosive environments.

- Custom Fabrication from prototypes to high-volume production, tailored to your exact specifications.

Let us help you solve your toughest engineering challenges. Contact our experts today to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs