At its core, PTFE's flexibility is what allows it to physically deform and conform to the minute imperfections of a mating surface. This creates an exceptionally tight and reliable barrier by eliminating the microscopic leak paths that exist between even the most precisely machined components. Its ability to maintain this contact under pressure, motion, and temperature variations is fundamental to its performance as a sealing material.

The true value of PTFE's flexibility isn't just its ability to bend, but its capacity to maintain a consistent and adaptive sealing force across imperfect surfaces and under demanding dynamic conditions, ensuring reliability where rigid materials would fail.

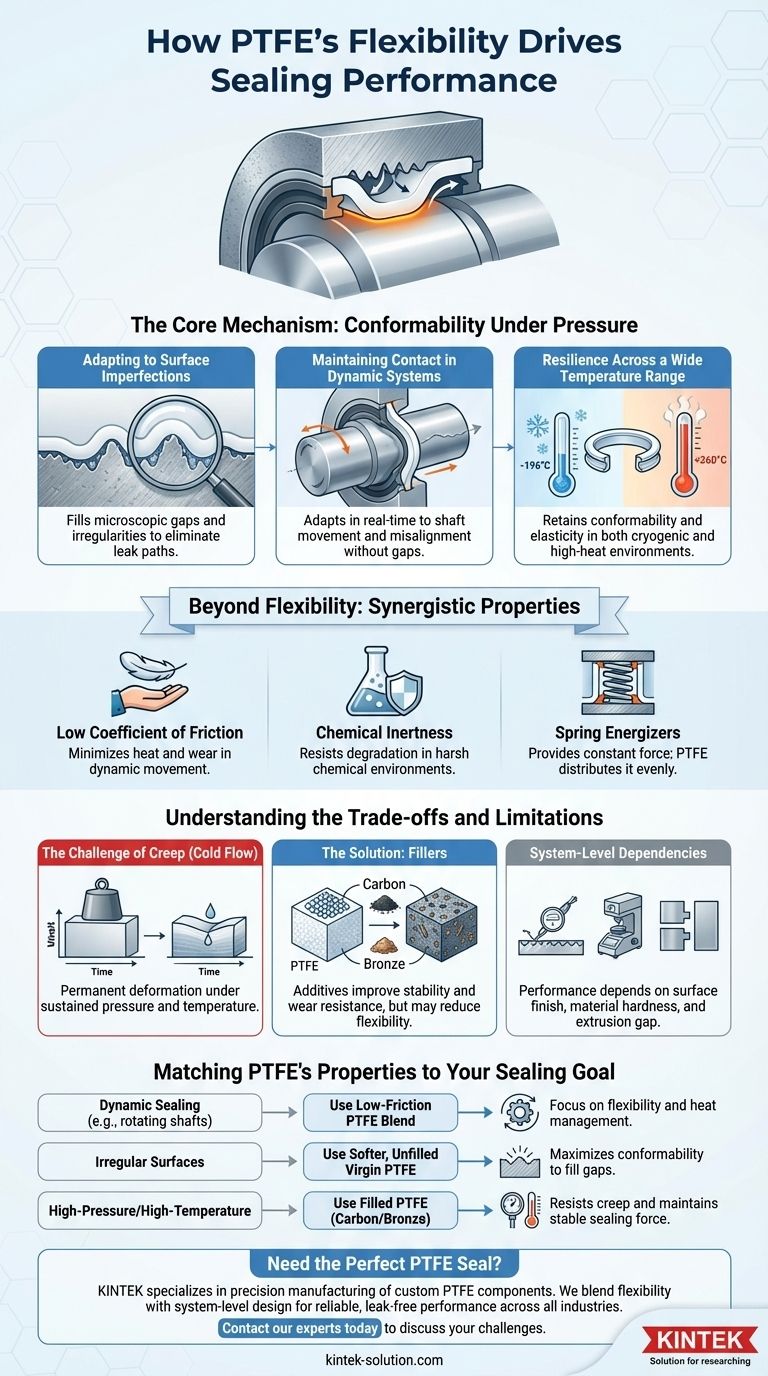

The Core Mechanism: Conformability Under Pressure

The primary function of any seal is to create a barrier. PTFE's physical properties make it uniquely suited for this task by allowing it to adapt perfectly to its environment.

Adapting to Surface Imperfections

No industrial surface is perfectly flat. Under a microscope, even polished metal has peaks and valleys.

PTFE’s flexibility allows it to be compressed into these microscopic irregularities, creating a seal with virtually no gaps for fluid or gas to escape.

Maintaining Contact in Dynamic Systems

In applications with rotating or oscillating shafts, the sealing surface is in constant motion and subject to minor misalignments.

The material's elasticity allows the seal lip to stay in constant contact with the shaft, adjusting in real-time to maintain the barrier without generating excessive friction or wear.

Resilience Across a Wide Temperature Range

A material's flexibility can change dramatically with temperature, but PTFE is remarkably stable.

It retains its conformability and elasticity in both cryogenic and high-heat environments, allowing it to absorb shocks and thermal stresses that would cause more brittle materials to crack and fail.

Beyond Flexibility: Synergistic Properties

Flexibility alone is not enough to create a world-class seal. PTFE’s effectiveness comes from a combination of properties that work together.

Low Coefficient of Friction

PTFE is famously "non-stick." This low friction is critical in dynamic seals.

It allows the flexible seal lip to move against a shaft with minimal heat generation, which prevents material degradation and extends the life of both the seal and the hardware.

Chemical Inertness

A seal is useless if it degrades upon contact with the substance it's meant to contain.

PTFE's ability to resist nearly all industrial chemicals means its physical properties, including flexibility, remain intact even in highly corrosive environments. This ensures the seal doesn't swell, harden, or break down over time.

The Role of Spring Energizers

In many advanced seals, a metal spring is used to provide a constant energizing force on the PTFE jacket.

The flexibility of the PTFE jacket is what allows it to evenly transmit this mechanical force from the spring to the sealing surface, ensuring a consistent and reliable seal even at low pressures.

Understanding the Trade-offs and Limitations

While powerful, PTFE's flexibility is not without its challenges. Acknowledging these limitations is critical for successful seal design.

The Challenge of Creep (Cold Flow)

The primary drawback of PTFE's deformability is its susceptibility to creep, also known as cold flow.

Under sustained pressure and temperature, the material can slowly and permanently deform, which can reduce the sealing force over time and eventually lead to a leak.

The Need for Fillers

To counteract cold flow, PTFE is often blended with fillers like carbon, fiberglass, or bronze.

These additives significantly improve the material's dimensional stability and wear resistance. However, they can slightly reduce its raw flexibility and chemical resistance, creating a necessary design trade-off.

System-Level Dependencies

The performance of a PTFE seal is not determined by the material alone.

Success depends heavily on the entire system, including the hardware's surface finish, the hardness of the mating parts, and the management of the extrusion gap (the clearance between components). A poor design in any of these areas will cause even the best seal to fail.

Matching PTFE's Properties to Your Sealing Goal

To leverage PTFE's flexibility effectively, you must align its specific formulation with the demands of your application.

- If your primary focus is dynamic sealing (e.g., rotating shafts): Rely on the flexibility of a low-friction PTFE blend to maintain constant contact, but ensure the system is designed to manage heat and wear.

- If your primary focus is sealing irregular or rough surfaces: Choose a softer, unfilled virgin PTFE for its superior ability to conform and fill in microscopic gaps in static applications.

- If your primary focus is high-pressure or high-temperature sealing: Select a filled PTFE (e.g., carbon or bronze-filled) to gain the necessary resistance to creep and maintain a stable sealing force over time.

Ultimately, understanding that PTFE's flexibility is a powerful but not absolute advantage is the key to designing a reliable and long-lasting seal.

Summary Table:

| PTFE Sealing Attribute | Key Contribution |

|---|---|

| Conformability | Fills microscopic surface imperfections to eliminate leak paths. |

| Dynamic Resilience | Maintains constant contact with moving parts under misalignment. |

| Thermal Stability | Retains flexibility and elasticity across cryogenic to high-heat environments. |

| Low Friction | Reduces wear and heat generation in dynamic applications. |

| Chemical Inertness | Ensures flexibility and integrity are maintained in corrosive media. |

Need a PTFE seal that perfectly balances flexibility, durability, and chemical resistance for your demanding application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. We understand the critical interplay between material properties like flexibility and system-level design requirements. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can help you select or fabricate the ideal PTFE solution—from prototypes to high-volume orders—to ensure leak-free performance and long-term reliability.

Contact our experts today to discuss your specific sealing challenges and discover how our tailored PTFE solutions can enhance your system's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications