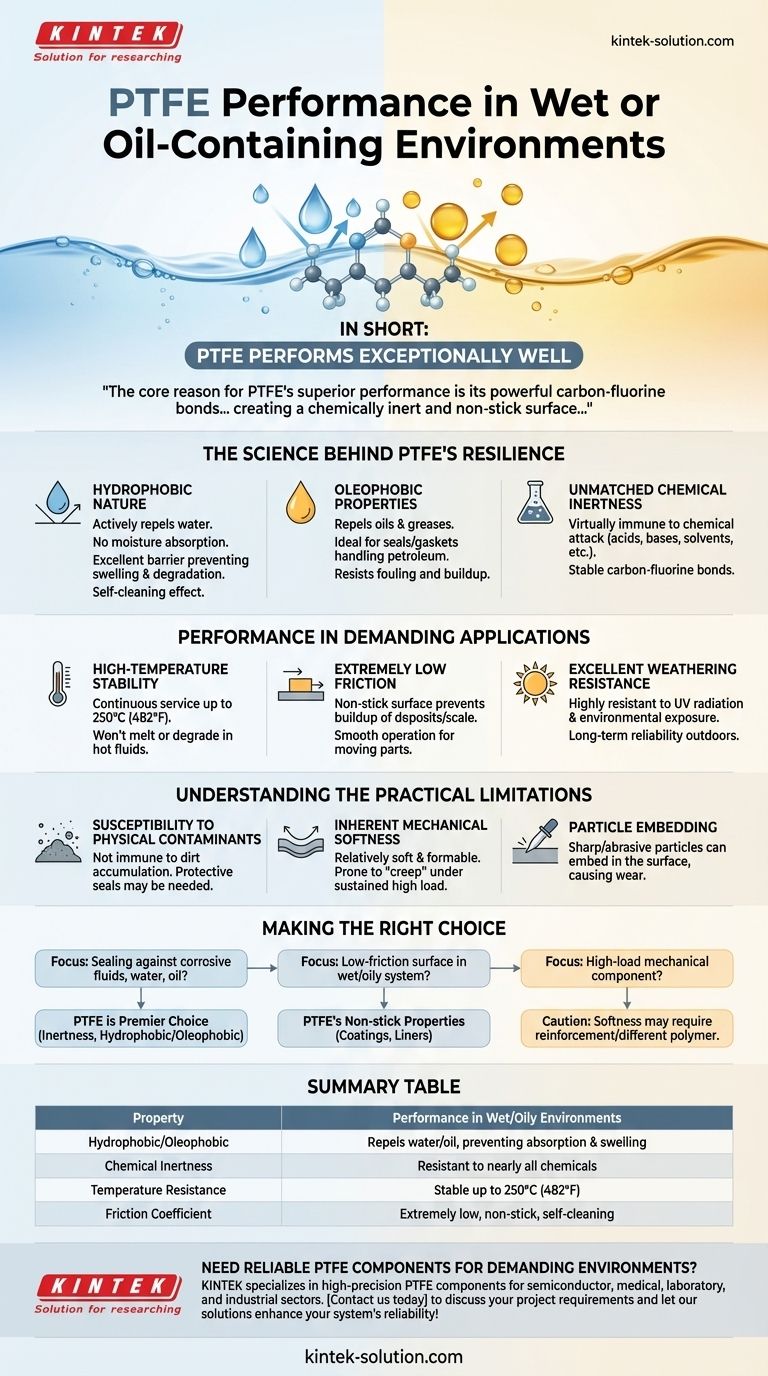

In short, Polytetrafluoroethylene (PTFE) performs exceptionally well in wet or oil-containing environments. Its molecular structure makes it inherently hydrophobic (water-repelling) and oleophobic (oil-repelling), preventing absorption of these fluids. This, combined with its extreme chemical inertness, makes PTFE one of the most reliable materials for applications involving moisture, oils, and even aggressive chemicals.

The core reason for PTFE's superior performance is its powerful carbon-fluorine bonds. These bonds create a chemically inert and non-stick surface that actively repels both water and oil, ensuring stability and reliability where other materials would fail.

The Science Behind PTFE's Resilience

To understand why PTFE is so effective, we need to look at its fundamental properties. Its performance isn't a single feature but the result of several interconnected characteristics.

Its Hydrophobic Nature

PTFE is hydrophobic, which means it actively repels water. It does not absorb moisture, making it an excellent barrier material.

This property is critical for preventing swelling, degradation, or changes in mechanical properties when exposed to water or high humidity. It also contributes to a self-cleaning effect, as water beads up and rolls off the surface.

Its Oleophobic Properties

Just as it repels water, PTFE also repels oils and greases. This oleophobic quality makes it an ideal material for seals, gaskets, and washers in piping or process systems that handle petroleum or other oil-based fluids.

The surface resists fouling and buildup from oils, ensuring consistent performance and preventing contamination.

Unmatched Chemical Inertness

Perhaps PTFE's most famous characteristic is its virtual immunity to chemical attack. The carbon-fluorine bonds are exceptionally strong and stable.

This makes PTFE resistant to nearly all acids, bases, alcohols, solvents, and hydrocarbons. For components in chemically aggressive environments, PTFE is often the only viable polymer choice.

Performance in Demanding Applications

The inherent properties of PTFE translate directly into reliable performance in real-world industrial and commercial settings.

High-Temperature Stability

PTFE maintains its integrity at continuous service temperatures up to 250°C (482°F). This far exceeds the typical temperatures found in many industrial fluid systems, ensuring it will not melt or degrade when handling hot water or oil.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

In wet or oily environments, this non-stick surface prevents the buildup of deposits, scale, or biological films, ensuring that moving parts operate smoothly and fluid-handling systems remain clear.

Excellent Weathering Resistance

PTFE is highly resistant to degradation from UV radiation and general environmental exposure. This ensures long-term reliability for components used in outdoor applications or where they are exposed to the elements.

Understanding the Practical Limitations

While PTFE is an exceptional material, no solution is perfect. Acknowledging its trade-offs is key to using it effectively.

Susceptibility to Physical Contaminants

While chemically inert, PTFE is not immune to the accumulation of physical dirt or grit. For applications with heavy particulate contamination, a protective seal or housing may be necessary to prevent buildup around the PTFE component.

Inherent Mechanical Softness

PTFE is a relatively soft and formable material. This is a major advantage for creating tight, conforming seals, but it can be a disadvantage in high-pressure or high-load structural applications. Under sustained load, it can be prone to "creep" or deformation.

Particle Embedding

Because it is soft, sharp or abrasive particles can become embedded in the PTFE surface. This can sometimes be beneficial, as it can prevent a lodged particle from scratching a mating surface, but it also means the PTFE component itself is being worn away.

Making the Right Choice for Your Application

Choosing the right material requires aligning its properties with your primary goal.

- If your primary focus is sealing against corrosive fluids, water, or oil: PTFE is a premier choice due to its unmatched chemical inertness and hydrophobic/oleophobic nature.

- If your primary focus is a low-friction surface in a wet or oily system: PTFE's non-stick properties are ideal for coatings, liners, or components that must remain clean and move freely.

- If your primary focus is a high-load mechanical component: You should be cautious, as PTFE's softness may require reinforcement or the selection of a different, more rigid polymer.

Ultimately, PTFE's unique combination of properties makes it a uniquely reliable and durable material for the vast majority of wet and oily environments.

Summary Table:

| Property | Performance in Wet/Oily Environments |

|---|---|

| Hydrophobic/Oleophobic | Repels water and oil, preventing absorption and swelling |

| Chemical Inertness | Resistant to nearly all acids, bases, solvents, and hydrocarbons |

| Temperature Resistance | Stable up to 250°C (482°F) |

| Friction Coefficient | Extremely low, providing a non-stick, self-cleaning surface |

Need reliable PTFE components for demanding environments?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get parts that deliver superior performance and longevity in your specific wet or oily applications.

Contact us today to discuss your project requirements and let our solutions enhance your system's reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions