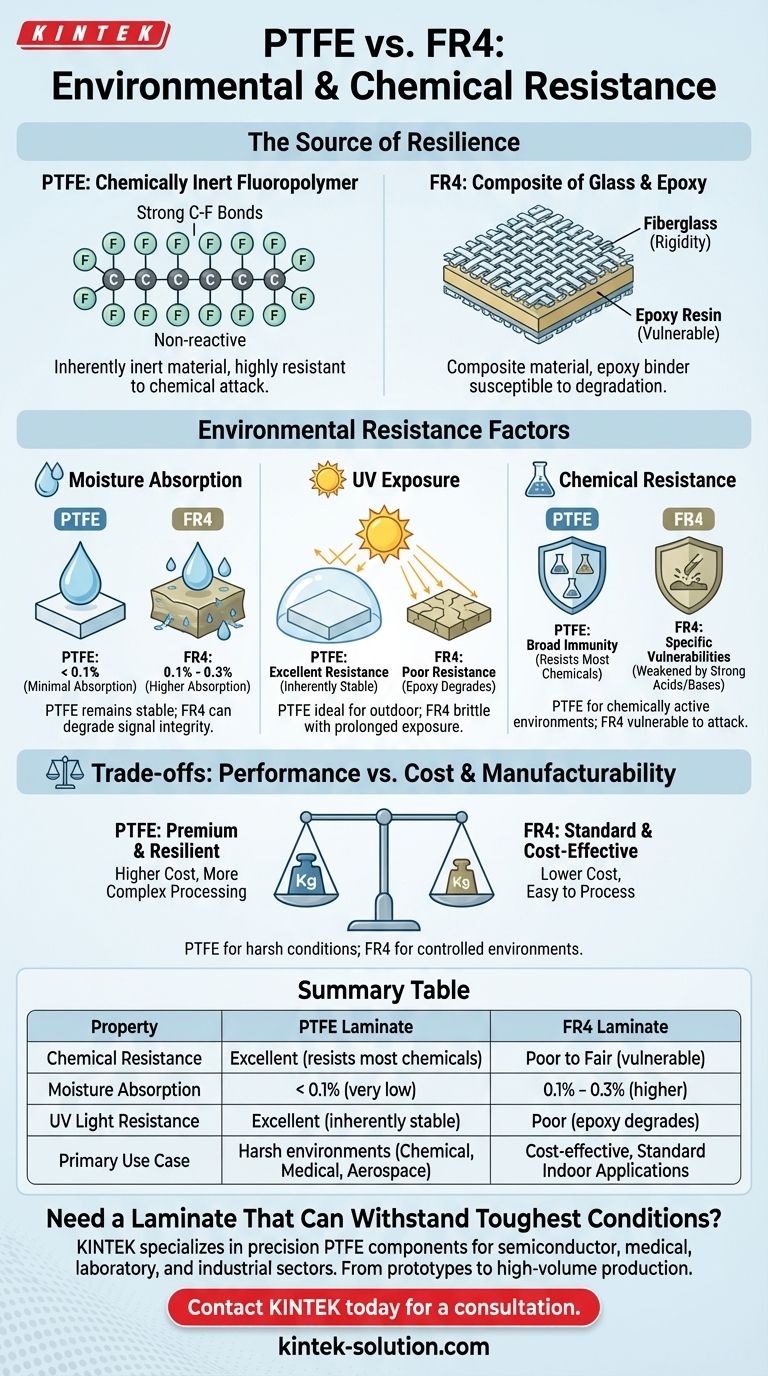

In terms of environmental and chemical durability, PTFE laminate is fundamentally superior to FR4. PTFE's molecular structure makes it nearly immune to chemical attack and moisture absorption, whereas FR4's epoxy resin binder is vulnerable to degradation from moisture, long-term UV exposure, and a range of common chemicals.

The core difference is not a matter of degree, but of kind. PTFE is an inherently inert material designed for stability in harsh conditions, while FR4 is a cost-effective composite whose vulnerabilities must be managed by controlling its operating environment.

The Source of a Material's Resilience

The stark contrast in resistance between PTFE and FR4 originates from their fundamental chemical makeup. Understanding this is key to selecting the right material for your application.

PTFE: A Chemically Inert Fluoropolymer

PTFE (Polytetrafluoroethylene) is a fluoropolymer. Its structure consists of a carbon chain completely shielded by fluorine atoms.

These carbon-fluorine bonds are exceptionally strong and stable, creating a non-reactive surface that is highly resistant to chemical attack.

FR4: A Composite of Glass and Epoxy

FR4 is not a single material but a composite. It combines woven fiberglass cloth with a flame-retardant epoxy resin binder.

While the fiberglass provides structural rigidity, it is the epoxy resin that is susceptible to environmental and chemical degradation.

Key Environmental Resistance Factors

For applications exposed to the elements, two factors are critical: moisture and ultraviolet (UV) light.

Moisture Absorption

PTFE exhibits minimal moisture absorption, typically less than 0.1%. This means its electrical and mechanical properties remain remarkably stable even in high-humidity or submerged applications.

FR4 absorbs significantly more moisture, with rates ranging from 0.1% to 0.3%. This absorbed water can alter its dielectric constant and dissipation factor, degrading high-frequency signal integrity over time.

UV Exposure

PTFE is inherently resistant to UV radiation, making it an excellent choice for outdoor and aerospace applications where long-term sun exposure is a certainty.

The epoxy in FR4, however, can degrade and become brittle with prolonged exposure to UV light, compromising the long-term structural integrity of the laminate.

A Closer Look at Chemical Resistance

The ability to withstand chemical exposure is often a non-negotiable requirement in industrial, medical, or automotive electronics.

PTFE's Broad Immunity

PTFE is renowned for its resistance to a vast range of chemicals, including aggressive solvents, acids, and alkalis. This inertness ensures reliable performance in chemically active environments.

FR4's Specific Vulnerabilities

The epoxy binder in FR4 can be attacked and weakened by certain strong acids, bases, and organic solvents. This can lead to delamination, material swelling, or a complete loss of insulating properties.

Understanding the Trade-offs

While PTFE's performance is superior, the decision is not always straightforward. Practical constraints often dictate the final choice.

The Performance vs. Cost Equation

FR4 is the industry standard for most consumer and commercial electronics for one simple reason: it is significantly less expensive. Its properties are more than adequate for controlled, benign environments.

PTFE is a premium material. Its higher cost is justified only when the application demands a level of environmental or chemical resilience that FR4 cannot provide.

Manufacturability and Processing

FR4 is a well-understood material that is easy to process using standard manufacturing techniques.

PTFE laminates can be more challenging to drill, machine, and process, which can add to the total manufacturing cost and complexity.

Making the Right Choice for Your Application

Selecting the correct laminate requires a clear understanding of your product's entire life cycle and operating environment.

- If your primary focus is reliability in harsh chemical environments: PTFE is the only viable choice due to its inherent chemical inertness.

- If your primary focus is stable performance in high-humidity or wet conditions: PTFE's extremely low moisture absorption ensures consistent electrical properties where FR4 could fail.

- If your primary focus is cost-effectiveness for standard indoor applications: FR4 provides sufficient protection and excellent performance for controlled environments.

Ultimately, choosing the right material is about matching its inherent stability to the specific environmental and chemical demands of your design.

Summary Table:

| Property | PTFE Laminate | FR4 Laminate |

|---|---|---|

| Chemical Resistance | Excellent (resists most solvents, acids, alkalis) | Poor to Fair (vulnerable to strong chemicals) |

| Moisture Absorption | < 0.1% (very low) | 0.1% - 0.3% (higher) |

| UV Light Resistance | Excellent (inherently stable) | Poor (epoxy degrades) |

| Primary Use Case | Harsh environments (chemical, medical, aerospace) | Cost-effective, standard indoor applications |

Need a Laminate That Can Withstand Your Toughest Conditions?

When your application demands maximum reliability against moisture, chemicals, or UV exposure, standard FR4 may not be enough. PTFE's inherent inertness provides the stability you need for long-term performance in harsh environments.

KINTEK specializes in precision PTFE components—including custom laminates, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine material expertise with custom fabrication capabilities, from prototypes to high-volume production.

Let us help you select or manufacture the right material for your critical application.

Contact KINTEK today for a consultation to discuss your specific requirements and how our PTFE solutions can enhance your product's durability.

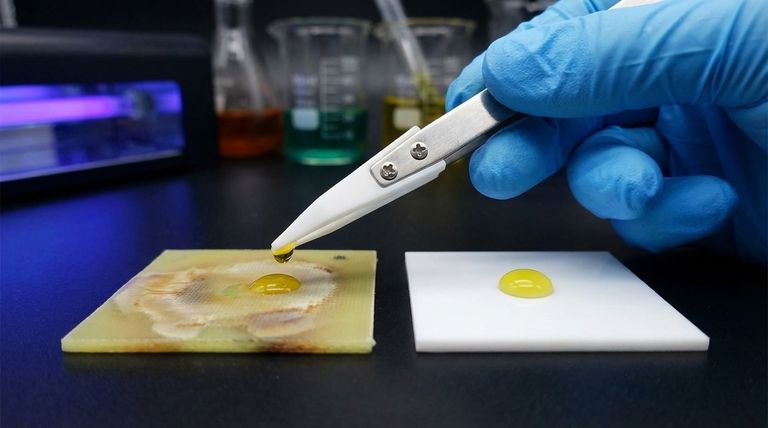

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments