At its core, impregnating PTFE gland packing with silicone oil creates a synergistic material that dramatically enhances sealing performance. The silicone oil acts as a clean, highly effective lubricant that minimizes friction and heat, while the chemically inert and dimensionally stable PTFE yarn provides the resilient sealing body for long-term service.

This combination isn't just about adding a lubricant; it's about creating a self-lubricating, low-friction seal that minimizes shaft wear and maintains consistent sealing pressure over time, especially in high-speed and contamination-sensitive applications.

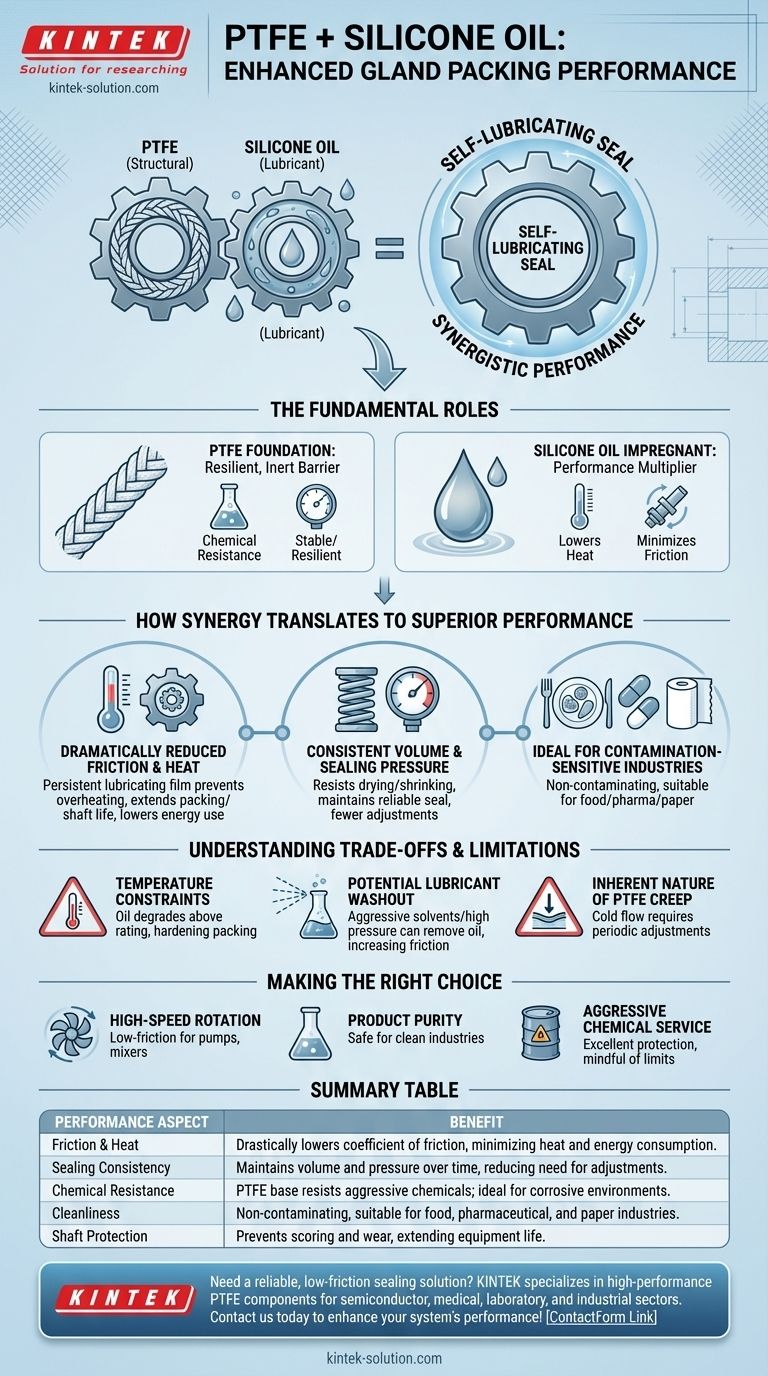

The Fundamental Roles of Each Component

To understand the performance improvement, you must first appreciate the distinct role each material plays. The final product is more than the sum of its parts.

The PTFE Foundation: A Resilient, Inert Barrier

The packing begins as a braided yarn of pure Polytetrafluoroethylene (PTFE). This material forms the structural backbone of the seal.

Its primary advantage is its exceptional chemical inertness. PTFE is resistant to nearly all corrosive and oxidative chemicals, making it a default choice for aggressive service.

Furthermore, PTFE is inherently stable and resilient, which is critical for maintaining the shape and volume of the packing under pressure.

The Silicone Oil Impregnant: A Performance Multiplier

The PTFE braid is then impregnated with a specialized silicone oil. This is not a generic lubricant; it is chosen for its stability and purity.

The oil's main function is to drastically lower the coefficient of friction between the packing and the rotating shaft.

This is the key to preventing the two most common failure modes: excessive heat generation and shaft scoring.

How Synergy Translates to Superior Performance

The real value emerges when these two materials work together within the gland, directly addressing common sealing challenges.

Dramatically Reduced Friction and Heat

The silicone oil creates a persistent lubricating film. At high peripheral speeds, this film prevents the packing from overheating and burning.

Reduced heat not only extends the packing's life but also prevents damage to the shaft, a costly and time-consuming repair.

This lower friction also translates to a direct reduction in the energy required to turn the shaft, contributing to operational efficiency.

Consistent Volume and Sealing Pressure

The references note that the packing "maintains its volume." This is a crucial point. Unlubricated or poorly lubricated packings can dry out, shrink, and harden.

The stable PTFE matrix, fully saturated with silicone oil, resists this degradation. It remains pliable and maintains consistent contact with the shaft and stuffing box.

This ensures a reliable, low-leakage seal over a much longer service life with fewer gland adjustments required.

Ideal for Contamination-Sensitive Industries

The combination of pure PTFE and clean silicone oil is critical for applications where product contamination is unacceptable.

This is why it is frequently specified in food processing, pharmaceutical manufacturing, and fine paper production. Nothing from the packing can leach into and compromise the final product.

Understanding the Trade-offs and Limitations

No material is perfect for every scenario. Acknowledging the limitations of this packing is key to using it successfully.

Temperature Constraints

While PTFE itself has a high temperature tolerance, the silicone oil lubricant is often the limiting factor.

At temperatures exceeding the oil's rating, it can begin to degrade or "cook off," which eliminates the low-friction benefit and can cause the packing to harden.

Potential for Lubricant Washout

In applications with highly aggressive solvents or high-pressure flush systems, the silicone oil can be "washed out" of the packing braid over time.

When this occurs, the packing begins to behave more like dry PTFE, leading to a significant increase in friction, heat, and potential shaft wear.

The Inherent Nature of PTFE Creep

All PTFE materials exhibit a property known as creep or "cold flow," where the material slowly deforms under sustained pressure.

While this packing is stable, it is not immune to creep. Proper installation techniques and periodic gland follower adjustments are still necessary to maintain optimal sealing pressure.

Making the Right Choice for Your Application

Use this packing when its specific strengths align with your operational goals.

- If your primary focus is high-speed rotation: The low-friction properties of this packing are ideal for minimizing heat buildup and shaft wear in pumps, mixers, and agitators.

- If your primary focus is product purity: Its suitability for food, pharmaceutical, and other clean industries makes it a safe and reliable choice to prevent contamination.

- If your primary focus is aggressive chemical service: The inert PTFE base provides excellent protection, but be mindful of the lubricant's temperature limits and the potential for washout.

By understanding how these materials work in concert, you can confidently specify this packing for applications where low friction, cleanliness, and long-term stability are paramount.

Summary Table:

| Performance Aspect | Benefit of PTFE + Silicone Oil |

|---|---|

| Friction & Heat | Drastically lowers coefficient of friction, minimizing heat and energy consumption. |

| Sealing Consistency | Maintains volume and pressure over time, reducing need for adjustments. |

| Chemical Resistance | PTFE base resists aggressive chemicals; ideal for corrosive environments. |

| Cleanliness | Non-contaminating, suitable for food, pharmaceutical, and paper industries. |

| Shaft Protection | Prevents scoring and wear, extending equipment life. |

Need a reliable, low-friction sealing solution for demanding applications? KINTEK specializes in manufacturing high-performance PTFE components, including custom gland packings impregnated with premium lubricants for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication—from prototypes to high-volume orders—ensure you get a seal that reduces downtime, protects equipment, and maintains purity. Contact us today to discuss your specific requirements and enhance your system's performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency