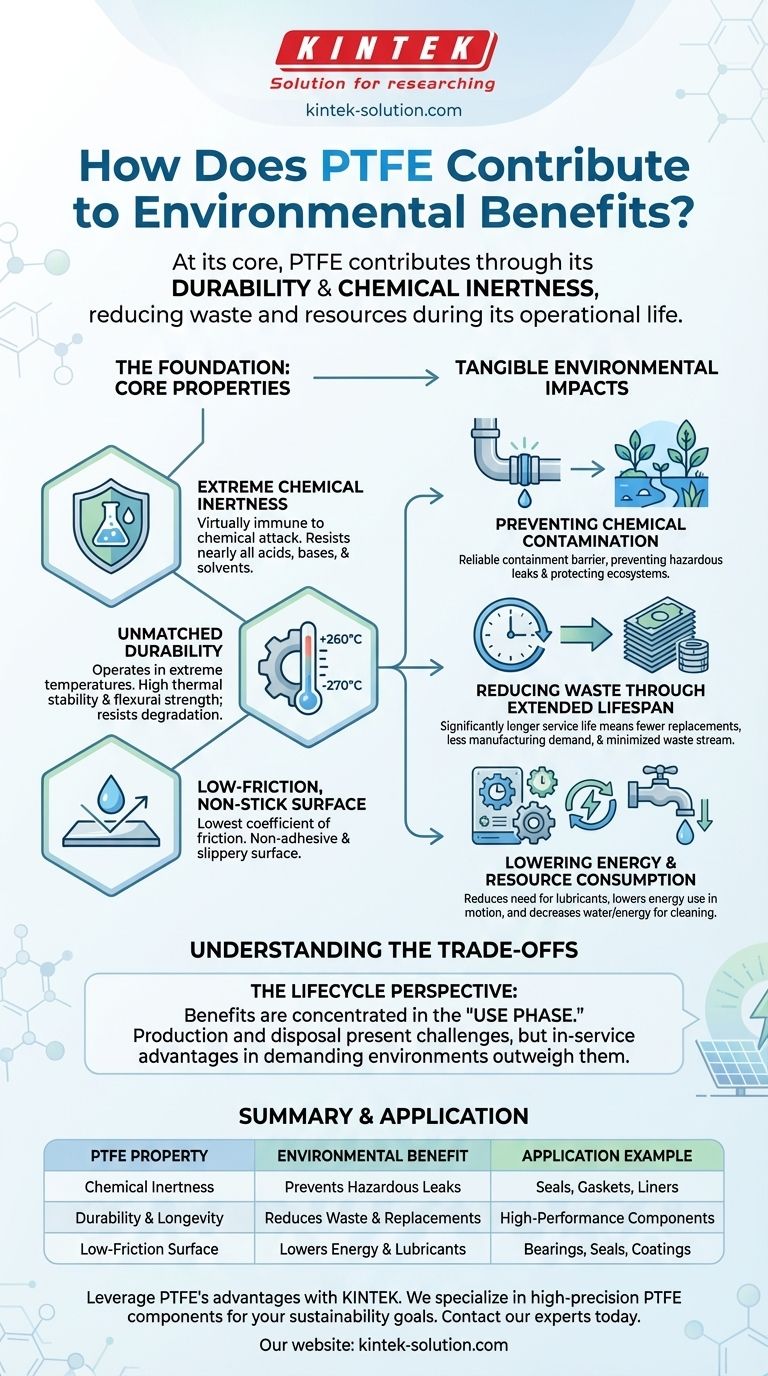

At its core, PTFE contributes to environmental benefits primarily through its durability and chemical inertness. This unique combination allows products made with or coated by PTFE to last significantly longer, reducing waste and the resources needed for replacements. Furthermore, its ability to safely contain corrosive chemicals prevents environmental contamination, while its low-friction surface reduces energy and lubricant consumption in industrial and everyday applications.

The environmental advantages of PTFE are not found in its creation, but in its operational performance. Its exceptional durability and chemical stability lead to a longer service life, reduced waste, and the prevention of chemical contamination, which collectively lower the overall environmental footprint of the systems it is part of.

The Foundation: How Core Properties Drive Efficiency

To understand PTFE's environmental contributions, we must first look at its fundamental characteristics. These properties are not just technical specifications; they are the direct cause of its positive in-service impact.

Extreme Chemical Inertness

The bond between carbon and fluorine atoms in PTFE is exceptionally strong, making the material virtually immune to chemical attack.

It resists nearly all acids, bases, and solvents. This stability is critical for applications like lining pipes and valves that handle corrosive substances.

Unmatched Durability and Longevity

PTFE operates effectively across an extremely wide temperature range, from as low as -270°C to over +260°C, with a high melting point around 347°C.

This thermal stability, combined with high flexural strength, means components made from PTFE do not easily degrade, crack, or fail under physical and thermal stress.

Low-Friction, Non-Stick Surface

PTFE has the lowest coefficient of friction of any known solid. Its surface is also non-adhesive, meaning other substances do not stick to it.

This inherent "slipperiness" is why it is used in non-stick cookware and, more critically, in industrial bearings and seals.

Tangible Environmental Impacts in Application

These core properties translate directly into measurable benefits that reduce environmental strain during a product's operational life.

Reducing Waste Through Extended Lifespan

Because PTFE components are so durable and resistant to degradation, they need to be replaced far less frequently.

This directly reduces the manufacturing demand for new parts and, most importantly, minimizes the amount of material entering the waste stream. A longer service life is a powerful tool for resource conservation.

Preventing Chemical Contamination

In industrial settings, the failure of a seal, gasket, or valve can lead to the release of hazardous chemicals into soil and waterways.

PTFE's non-reactive and non-corrosive nature provides a reliable containment barrier, preventing leaks and protecting ecosystems from direct chemical pollution.

Lowering Energy and Resource Consumption

The low-friction surface of PTFE reduces the need for industrial lubricants, decreasing the consumption of petroleum-based products and eliminating a potential source of contamination.

Similarly, textiles coated with PTFE repel water and stains, reducing the frequency of energy-intensive washing and dry cleaning. The material's water resistance also means less energy is required for drying.

Understanding the Trade-offs

An objective analysis requires acknowledging the complete picture. While PTFE's in-service performance offers clear benefits, it's important to frame them within the material's full lifecycle.

The Lifecycle Perspective

The environmental benefits discussed here are concentrated in the "use phase" of a product's life.

The production of fluoropolymers like PTFE is an energy-intensive process, and their end-of-life disposal presents distinct environmental challenges. These factors must be weighed against the in-service advantages.

Focus on Application-Specific Gains

The decision to use PTFE should be driven by applications where its unique properties solve a significant environmental or safety problem that other materials cannot.

Its value is most pronounced in harsh, demanding environments where material failure would have severe consequences, such as in chemical processing or critical industrial machinery.

Making the Right Choice for Your Application

To leverage PTFE's benefits effectively, align its properties with your primary environmental goal.

- If your primary focus is maximizing product lifespan and reducing replacement waste: PTFE's exceptional durability and resistance to thermal and physical stress make it an outstanding choice.

- If your primary focus is preventing the leakage of hazardous materials: PTFE's chemical inertness provides an unparalleled and reliable barrier for containment in corrosive environments.

- If your primary focus is improving operational efficiency and reducing maintenance: PTFE's low-friction and non-stick properties can significantly lower the need for energy, water, and lubricants.

Ultimately, PTFE's contribution is to enhance the efficiency, safety, and longevity of the systems in which it is used, creating a net positive environmental impact during its operational life.

Summary Table:

| PTFE Property | Primary Environmental Benefit | Key Application Example |

|---|---|---|

| Chemical Inertness | Prevents hazardous chemical leaks and contamination | Seals, gaskets, and liners for chemical processing |

| Durability & Longevity | Reduces replacement frequency and manufacturing waste | High-performance components in industrial machinery |

| Low-Friction Surface | Lowers energy and lubricant consumption | Bearings, seals, and non-stick coatings |

Leverage PTFE's environmental advantages in your operations. KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get durable, efficient parts that reduce waste and enhance safety. Contact our experts today to discuss how our PTFE solutions can benefit your application and sustainability goals.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties