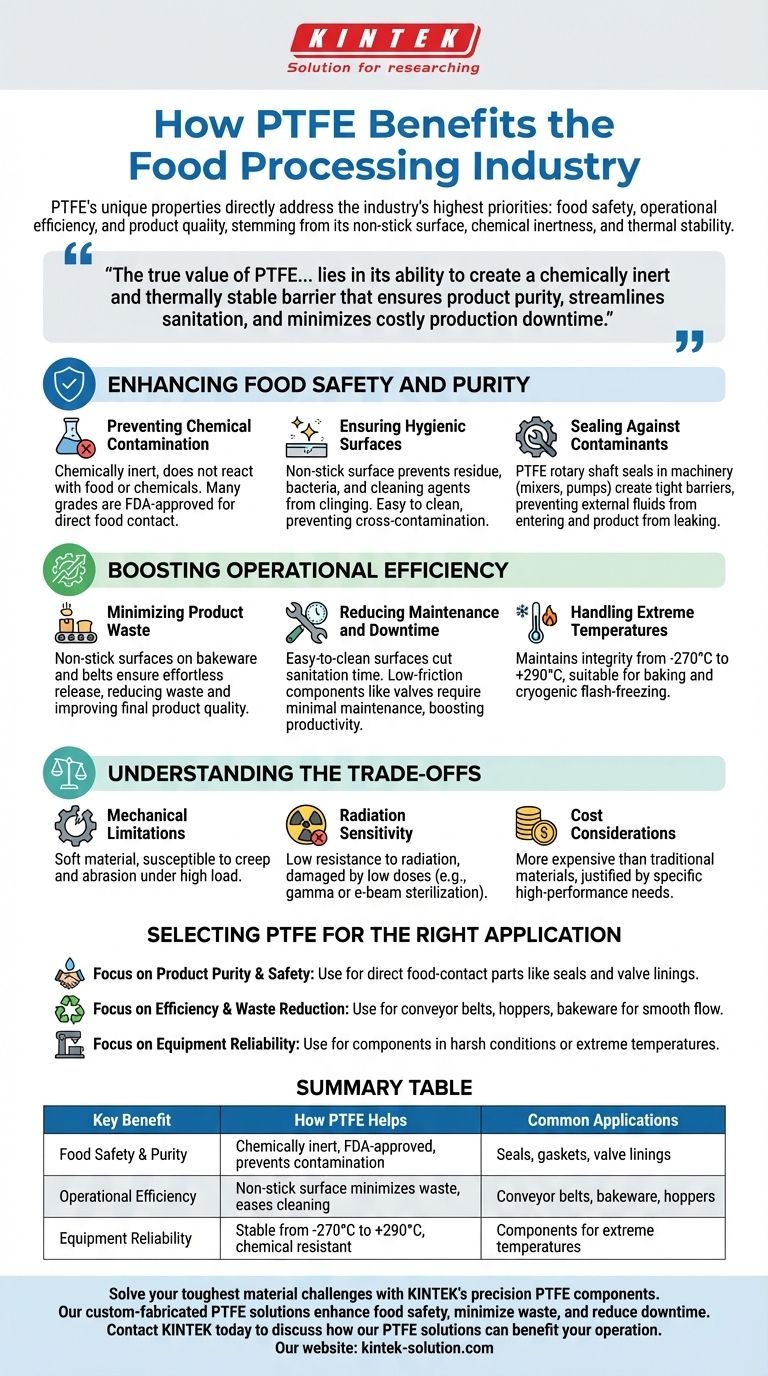

In the food processing industry, PTFE is a critical material because its unique combination of properties directly addresses the industry's highest priorities: food safety, operational efficiency, and product quality. Its benefits stem from three core characteristics: an extremely non-stick surface, near-universal chemical inertness, and stability across a vast range of temperatures.

The true value of PTFE in food processing extends beyond its well-known non-stick coating. Its real impact lies in its ability to create a chemically inert and thermally stable barrier that ensures product purity, streamlines sanitation, and minimizes costly production downtime.

Enhancing Food Safety and Purity

The primary challenge in food processing is preventing contamination. PTFE's material properties provide a powerful defense against chemical and biological contaminants at multiple points in the production line.

Preventing Chemical Contamination

PTFE is chemically inert, meaning it does not react with nearly all industrial chemicals, including the highly acidic or alkaline substances found in many food products. This ensures that the material itself does not leach into or react with the food.

Because of this stability and purity, many grades of PTFE are FDA-approved for direct food contact, making them a trusted choice for components that touch the final product.

Ensuring Hygienic Surfaces

The material's famous non-stick (anti-adhesion) surface is critical for hygiene. It prevents food residues, bacteria, and cleaning agents from clinging to equipment.

This quality makes surfaces exceptionally easy to clean, which is essential for preventing cross-contamination between batches and ensuring compliance with stringent sanitation standards.

Sealing Against Contaminants

In machinery like mixers and pumps, PTFE rotary shaft seals are used to create a tight barrier. These seals prevent lubricants or other external fluids from entering the product stream while also preventing the food product from leaking out, maintaining both purity and efficiency.

Boosting Operational Efficiency

Beyond safety, PTFE drives significant improvements in productivity and cost-effectiveness by reducing waste, maintenance, and equipment failure.

Minimizing Product Waste

On surfaces like PTFE-coated bakeware, sheets, and conveyor belts, the non-stick property ensures the effortless release of products. This dramatically reduces the amount of food that sticks to equipment, minimizing waste and improving the quality of the final product.

In packaging machinery, these coatings prevent sticky materials from adhering to moving parts, which keeps production lines running smoothly.

Reducing Maintenance and Downtime

The easy-to-clean nature of PTFE surfaces significantly cuts down on the time and labor required for sanitation cycles.

Furthermore, components like PTFE valves require minimal maintenance due to their high chemical resistance and low-friction operation, which reduces equipment downtime and boosts overall plant productivity.

Handling Extreme Temperatures

PTFE maintains its integrity across an exceptionally wide temperature range, from approximately -270°C to +290°C. This thermal stability makes it suitable for equipment used in both high-temperature baking and cryogenic flash-freezing processes.

Understanding the Trade-offs

While PTFE offers exceptional performance, it's essential to understand its limitations to apply it correctly. Its strengths in one area can create trade-offs in others.

Mechanical Limitations

PTFE is a relatively soft material with a low coefficient of friction, which is excellent for non-stick applications. However, it is not ideal for high-load, high-wear structural components, as it can be susceptible to creep and abrasion under significant mechanical stress.

Radiation Sensitivity

The material has a relatively low resistance to radiation, with damage occurring at doses as low as 0.02 Mrad. This can be a limiting factor in applications that rely on gamma or e-beam sterilization methods.

Cost Considerations

While noted as one of the most affordable fluoropolymers, PTFE is generally more expensive than traditional materials like stainless steel or commodity plastics. Its use is justified when its specific high-performance properties—chemical, thermal, or non-stick—are required to solve a critical problem.

Selecting PTFE for the Right Application

Choosing PTFE is about aligning its specific strengths with your primary operational goals.

- If your primary focus is product purity and safety: PTFE's chemical inertness and FDA-approved status make it the superior choice for direct food-contact parts like valve linings, gaskets, and seals.

- If your primary focus is efficiency and waste reduction: Its non-stick properties are invaluable for conveyor belts, hoppers, and bakeware to ensure smooth product flow and complete release.

- If your primary focus is equipment reliability in harsh conditions: The material's broad temperature range and chemical resistance make it ideal for components that must withstand aggressive cleaning agents or extreme processing temperatures.

Ultimately, leveraging PTFE allows you to solve some of the most complex material challenges in modern food production.

Summary Table:

| Key Benefit | How PTFE Helps | Common Applications |

|---|---|---|

| Food Safety & Purity | Chemically inert, FDA-approved, prevents contamination | Seals, gaskets, valve linings |

| Operational Efficiency | Non-stick surface minimizes waste, eases cleaning | Conveyor belts, bakeware, hoppers |

| Equipment Reliability | Stable from -270°C to +290°C, chemical resistant | Components for extreme temperatures |

Solve your toughest material challenges with KINTEK's precision PTFE components.

Our custom-fabricated PTFE seals, liners, and labware are engineered to enhance food safety, minimize product waste, and reduce equipment downtime in the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we prioritize precision production to meet your specific needs.

Contact KINTEK today to discuss how our PTFE solutions can benefit your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F