In construction, Polytetrafluoroethylene (PTFE) provides critical advantages as a high-performance problem-solver. It is most commonly used for insulating electrical wiring and plumbing systems, where its resistance to heat and electricity is paramount. Its unique properties also make it an ideal material for essential components like valves, seals, and gaskets in demanding fluid and gas handling systems.

The core value of PTFE in construction is not as a primary structural material, but as a specialized component that dramatically enhances the longevity, safety, and efficiency of systems exposed to chemicals, extreme temperatures, or high friction.

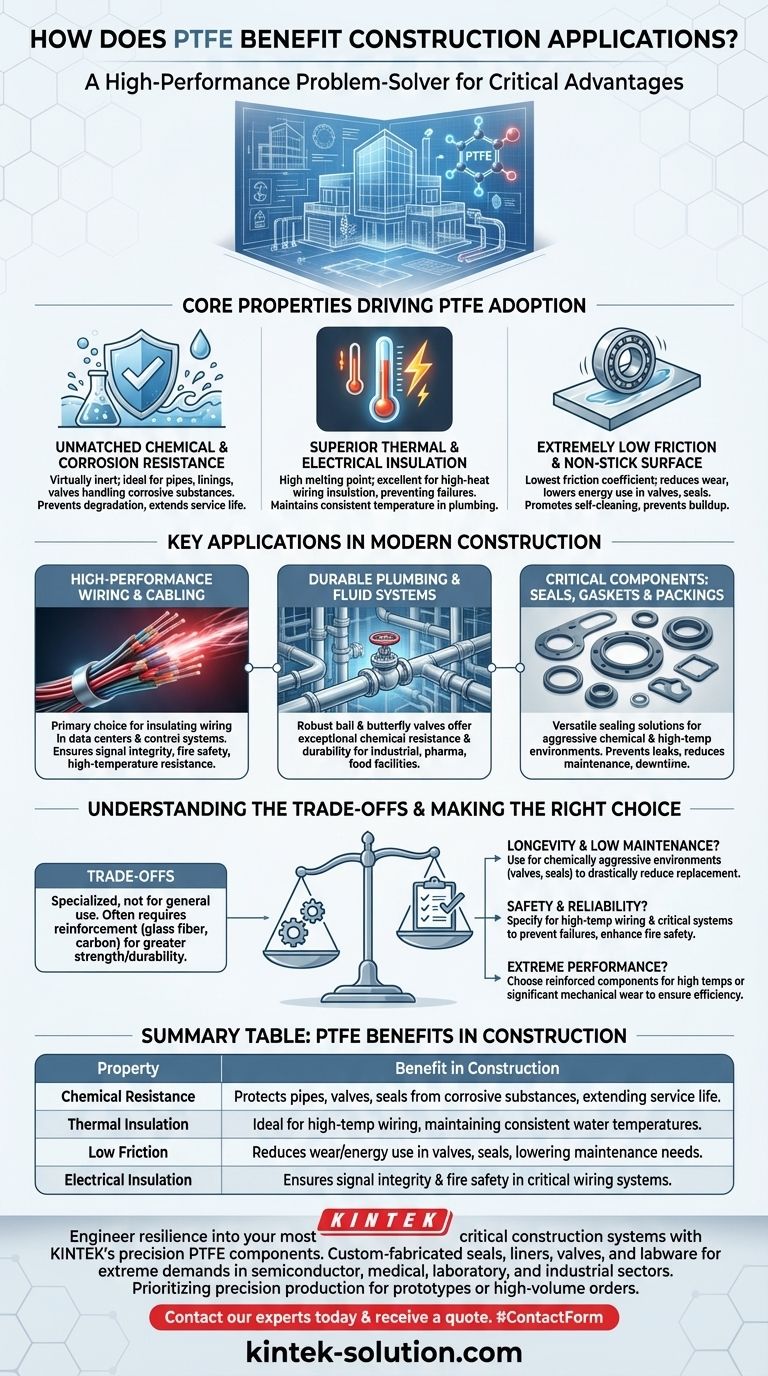

The Core Properties Driving PTFE Adoption

The benefits of PTFE stem from a unique combination of chemical, thermal, and physical properties that outperform conventional plastics in specific, challenging environments.

Unmatched Chemical and Corrosion Resistance

PTFE is virtually inert, meaning it does not react with the vast majority of industrial chemicals. This makes it an ideal material for pipes, linings, and valves that handle corrosive substances.

Its resistance to water and oil also prevents degradation and ensures a long service life for components, minimizing the need for costly replacements.

Superior Thermal and Electrical Insulation

With a very high melting point, PTFE is exceptionally suited for high-heat applications, particularly as insulation for electrical wiring where it prevents failures and improves safety.

In plumbing, its thermal insulation properties help maintain consistent water temperatures in pipes, regardless of external temperature changes, contributing to system efficiency.

Extremely Low Friction and Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material, creating a "non-stick" surface. In components like valves and seals, this reduces wear and tear and lowers the energy required for operation.

This non-wetting property also promotes a self-cleaning effect in some applications, preventing buildup and ensuring consistent performance over time.

Key Applications in Modern Construction

These core properties translate directly into tangible benefits across several critical areas of a construction project, particularly where system reliability is non-negotiable.

High-Performance Wiring and Cabling

Due to its excellent dielectric properties and resistance to high temperatures, PTFE is a primary choice for insulating high-performance wiring. This ensures signal integrity and fire safety in everything from data centers to industrial control systems.

Durable Plumbing and Fluid Systems

In industrial, pharmaceutical, or food processing facilities, plumbing systems must be robust. PTFE ball and butterfly valves offer exceptional chemical resistance and durability, ensuring the safe and efficient control of liquids and gases.

Critical Components: Seals, Gaskets, and Packings

PTFE's ability to be molded and combined with other materials makes it highly versatile for sealing applications. PTFE gaskets and packings prevent leaks in aggressive chemical or high-temperature environments, reducing maintenance needs and industrial downtime.

Understanding the Trade-offs

While its benefits are significant, PTFE is a specialized material. Understanding its limitations is key to using it effectively.

The Need for Reinforcement

In its pure form, PTFE is not exceptionally strong or rigid. For applications requiring greater durability and mechanical strength, it is often blended with reinforcing agents like glass fiber, carbon, or graphite.

This blending process enhances specific properties like wear resistance or compressive strength while retaining PTFE's core benefits of low friction and chemical inertness.

Specialized Application, Not General Use

PTFE is a premium material engineered to solve specific problems. It is not a cost-effective replacement for general-purpose plastics in non-demanding applications. Its value is realized where other materials would quickly fail due to heat, chemical exposure, or friction.

Making the Right Choice for Your Project

Selecting PTFE is a strategic choice based on project priorities. Use the following guidelines to determine if it's the right fit.

- If your primary focus is longevity and low maintenance: Use PTFE for components in chemically aggressive environments, such as valves and seals in industrial fluid systems, to drastically reduce replacement cycles.

- If your primary focus is system safety and reliability: Specify PTFE-insulated wiring for high-temperature applications and critical electrical systems to prevent failures and enhance fire safety.

- If your primary focus is performance in extreme environments: Choose reinforced PTFE components for applications involving high temperatures or significant mechanical wear to ensure operational efficiency and durability.

Ultimately, incorporating PTFE is a strategic decision to engineer resilience and long-term performance into the most critical systems of your project.

Summary Table:

| Property | Benefit in Construction |

|---|---|

| Chemical Resistance | Protects pipes, valves, and seals from corrosive substances, extending service life. |

| Thermal Insulation | Ideal for high-temperature electrical wiring and maintaining consistent water temperatures. |

| Low Friction | Reduces wear and energy use in valves and seals, lowering maintenance needs. |

| Electrical Insulation | Ensures signal integrity and fire safety in critical wiring systems. |

Engineer resilience into your most critical construction systems with KINTEK's precision PTFE components.

Our custom-fabricated PTFE seals, liners, valves, and labware are designed to withstand extreme chemical, thermal, and mechanical demands, ensuring longevity and reliability for your projects in the semiconductor, medical, laboratory, and industrial sectors.

Whether you need prototypes or high-volume orders, we prioritize precision production to meet your exact specifications. Contact our experts today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability