At its core, EN 13555 is a testing standard that provides a common language for gasket performance. It allows you to directly compare different PTFE gaskets using objective, empirical data on critical factors like required seating stress, maximum pressure tolerance, and quantifiable leakage rates under specific conditions.

The standard transforms gasket selection from a process based on generic material properties into a precise engineering decision. It replaces assumptions about a material's behavior with hard data, allowing you to predict how a specific gasket will perform in your actual flange assembly.

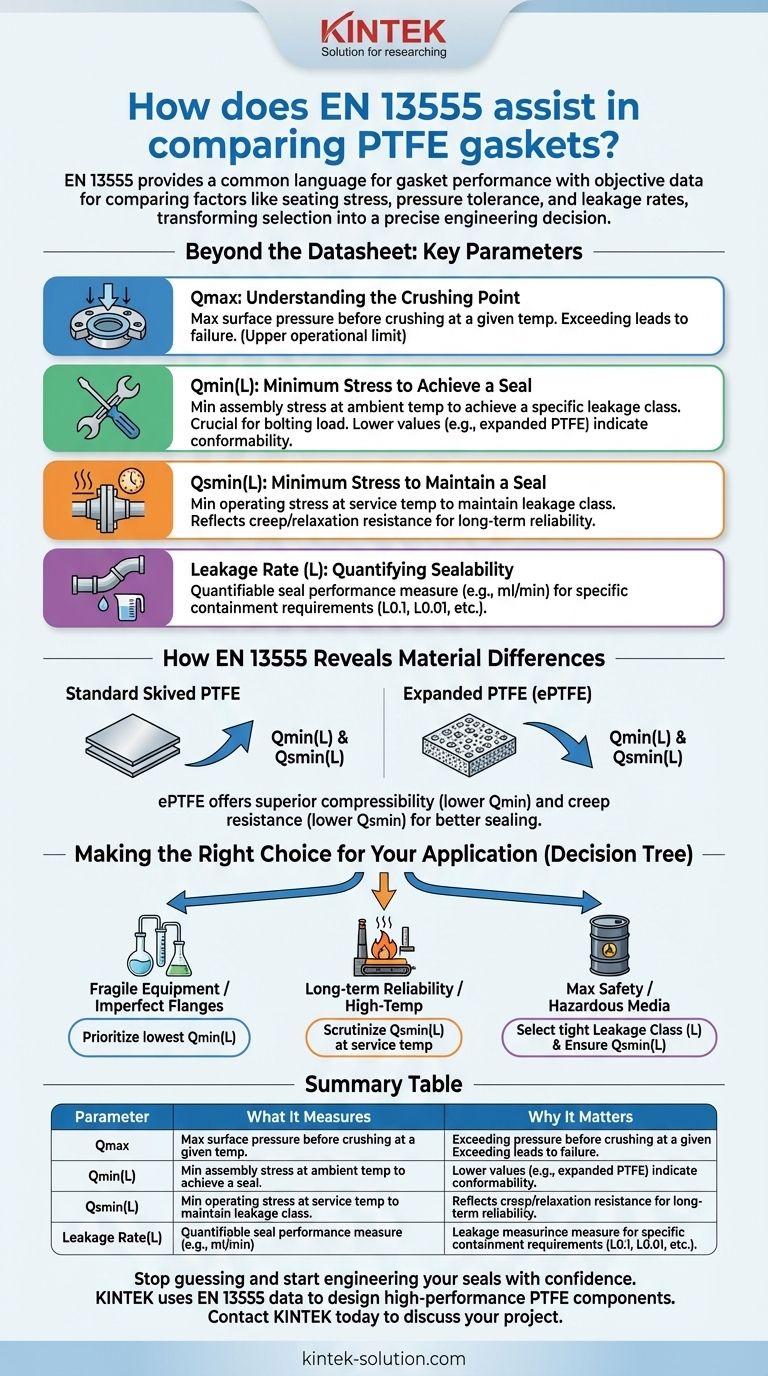

Beyond the Datasheet: Why EN 13555 Matters

Traditional datasheets often provide vague properties like "good chemical resistance" or "high compressibility." EN 13555 provides specific, test-derived parameters that directly relate to the performance of a bolted flange joint.

Qmax: Understanding the Crushing Point

Qmax represents the maximum surface pressure a gasket can withstand at a given temperature before it is crushed or its integrity is critically compromised.

This is your upper operational limit. Exceeding this value can lead to mechanical failure of the gasket and a catastrophic loss of the seal.

Qmin(L): Minimum Stress to Achieve a Seal

Qmin(L) is the minimum gasket stress required during assembly (at ambient temperature) to achieve a specific leakage class (L).

This parameter is crucial for understanding if your flange and bolting can generate enough load to make the gasket seal effectively in the first place. Materials with a lower Qmin, like expanded PTFE, are more conformable and can seal effectively even on less-than-perfect flange surfaces or in assemblies with limited bolt load.

Qsmin(L): Minimum Stress to Maintain a Seal

Qsmin(L) defines the minimum gasket stress required during operation (at the service temperature) to maintain that same leakage class (L).

This is arguably the most critical parameter for long-term reliability. It directly reflects the gasket's resistance to creep and relaxation. A significant difference between Qmin and Qsmin indicates the material loses significant sealing stress under load and temperature, increasing the risk of future leaks.

Leakage Rate (L): Quantifying Sealability

The leakage rate provides a tangible measure of sealing performance (e.g., in ml/min). The standard defines several leakage classes (L0.1, L0.01, etc.).

This allows you to select a gasket that meets the specific containment requirements of your application, whether you are handling water or a highly volatile, hazardous gas.

How EN 13555 Reveals Material Differences

Consider the comparison between a standard, skived PTFE gasket and an expanded PTFE (ePTFE) gasket sheet.

The Advantage of Compressibility

An ePTFE gasket's superior compressibility will be reflected in a lower Qmin(L) value. This proves it requires less bolt load to conform to flange imperfections and create an initial, effective seal.

The Impact of Creep Resistance

The superior creep resistance of ePTFE will result in a lower Qsmin(L) value. This demonstrates its ability to maintain sealing stress over time, especially at elevated temperatures, ensuring a more reliable, long-term joint.

Common Pitfalls in Gasket Comparison

Relying on this data requires understanding its context to avoid misinterpretation.

Focusing on a Single Parameter

A gasket with a very high Qmax is not necessarily better. If your assembly cannot generate the required Qmin to even seal it, its high-pressure tolerance is irrelevant. Gasket selection requires a holistic view of all parameters.

Ignoring Application-Specific Conditions

The EN 13555 data is generated under controlled laboratory conditions. You must always compare the test data (especially temperature) to your actual operating conditions, including the media being sealed and the condition of your flanges.

Misinterpreting Leakage Classes

Striving for the tightest possible leakage class (e.g., L0.001) is not always necessary and may demand extremely high, and potentially damaging, bolt loads. You must select the leakage class that is appropriate and safe for the service fluid.

Making the Right Choice for Your Application

Use the EN 13555 parameters to align the gasket's performance with your primary operational goal.

- If your primary focus is sealing on fragile equipment (e.g., glass-lined steel) or older, imperfect flanges: Prioritize a gasket with the lowest Qmin(L), as this indicates it requires minimal stress to conform and seal.

- If your primary focus is long-term reliability in a critical or high-temperature application: Scrutinize the Qsmin(L) values at your service temperature to ensure the gasket will resist creep and maintain its seal.

- If your primary focus is maximum safety and containment of hazardous media: Select a gasket proven to achieve the necessary tight leakage class (L) and ensure your assembly can generate and maintain the corresponding Qsmin(L) stress.

Ultimately, EN 13555 empowers you to make an informed, data-driven decision that ensures the safety and reliability of your bolted flange connections.

Summary Table:

| EN 13555 Parameter | What It Measures | Why It Matters |

|---|---|---|

| Qmax | Maximum surface pressure before crushing | Defines the upper operational limit for pressure. |

| Qmin(L) | Minimum assembly stress to achieve a seal | Determines if your bolting can create an initial seal. |

| Qsmin(L) | Minimum operating stress to maintain a seal | Critical for assessing long-term creep resistance and reliability. |

| Leakage Rate (L) | Quantifiable leak rate (e.g., ml/min) | Allows selection based on specific containment requirements. |

Stop guessing and start engineering your seals with confidence.

The objective data from EN 13555 is exactly what we use at KINTEK to design and manufacture high-performance PTFE components. Whether you need standard seals or custom-fabricated gaskets for the semiconductor, medical, laboratory, or industrial sectors, our precision production ensures your flanges are safe and reliable.

Let us provide you with the right PTFE solution for your specific Qmin, Qsmin, and leakage class requirements.

Contact KINTEK today to discuss your project and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications