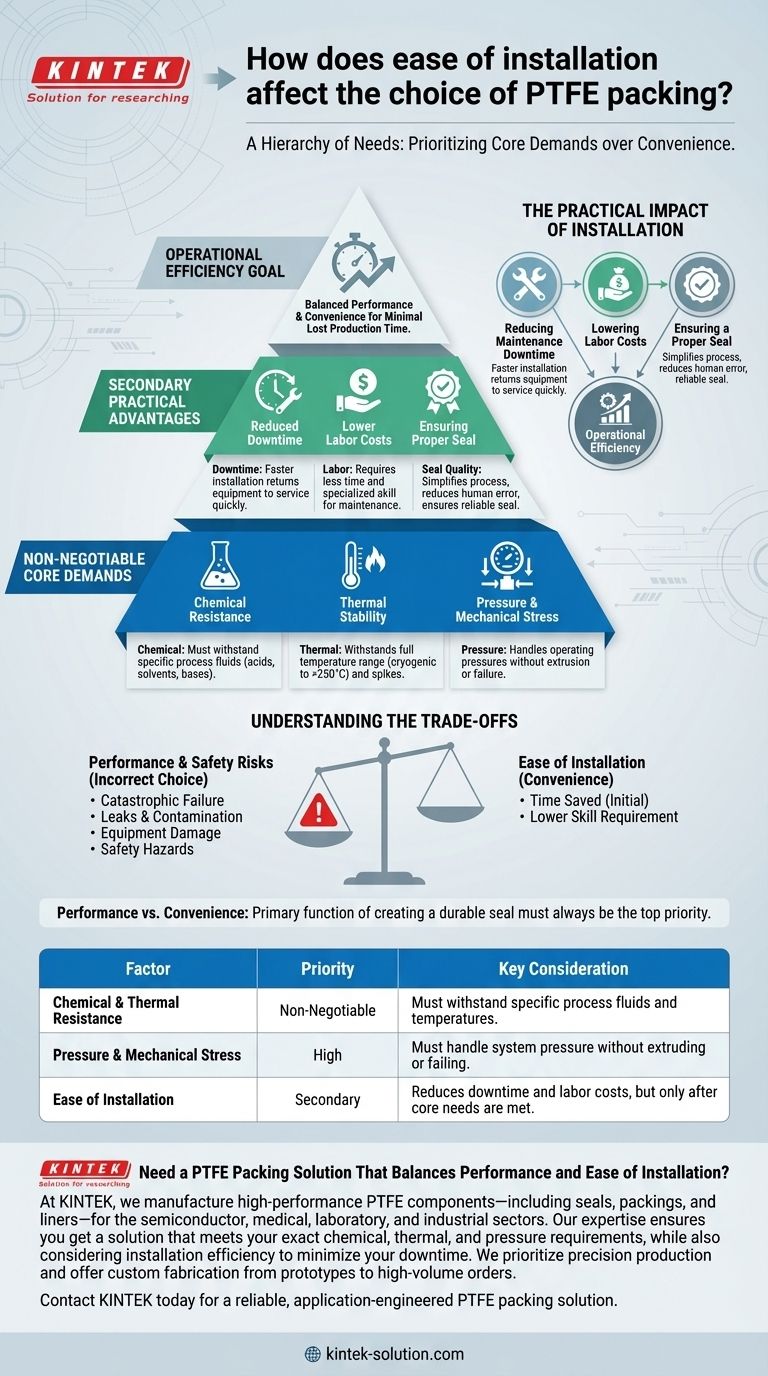

While ease of installation is a significant practical advantage, it should be treated as a secondary factor when selecting PTFE packing. Designs engineered for simpler installation, such as certain PTFE gland packings, directly reduce equipment downtime and labor costs during maintenance. However, this convenience must never compromise the packing's ability to meet the fundamental operational demands of the application.

The core decision-making process for selecting PTFE packing is a hierarchy of needs. Ease of installation is a critical factor for operational efficiency, but it must only be considered after the packing has met the non-negotiable requirements of chemical, thermal, and pressure resistance for your specific environment.

The Practical Impact of Installation on Operations

Choosing a packing that is easier to install offers clear, tangible benefits that directly affect your maintenance budget and equipment availability.

Reducing Maintenance Downtime

Faster and simpler installation procedures mean that critical equipment is returned to service more quickly. This directly minimizes lost production time, which is often the most significant cost associated with maintenance.

Lowering Labor Costs

A packing designed for easy installation requires less time and potentially less specialized skill from maintenance personnel. This translates to lower direct labor costs for each servicing event.

Ensuring a Proper Seal

Complex installation processes increase the risk of human error, which can lead to an improper seal, leaks, and premature failure. An easier-to-install packing helps ensure a reliable and effective seal from the start.

Prioritizing the Core Operational Demands

Before considering the convenience of installation, you must verify that the packing can survive and perform in its intended environment. These core factors are non-negotiable.

Chemical Compatibility is Essential

PTFE is renowned for its exceptional resistance to aggressive chemicals, including most acids, solvents, and bases. You must confirm the packing is compatible with the specific type and concentration of any chemicals it will contact. For extremely aggressive substances, a specialized variant like PTFE graphite packing may be required.

Thermal Stability is Crucial

The packing must be ableto withstand the full temperature range of the application. This includes not only the normal operating temperature but also any potential spikes or cryogenic conditions the system may experience. Standard PTFE performs reliably from cryogenic levels to over 250°C (482°F).

Pressure and Mechanical Stress

The selected packing must have the structural integrity to handle the system's operating pressures without extruding or failing. Its low coefficient of friction is a key advantage, as it reduces wear on shafts and lowers the energy required for operation.

Understanding the Trade-offs

Selecting packing solely for easy installation without considering its primary function is a common and costly mistake.

Performance vs. Convenience

The packing that is easiest to install may not be the most robust option for a high-pressure, high-temperature, or chemically aggressive service. The primary function of creating a durable seal must always be the top priority.

The High Cost of an Incorrect Choice

Choosing an inappropriate packing based on installation ease can lead to catastrophic failure. The consequences include leaks, damage to equipment shafts, process contamination, and significant safety hazards, all of which far outweigh any time saved during initial installation.

Specialized vs. General-Purpose Packing

While standard PTFE packing is highly versatile, extreme industrial applications often demand specialized composites. These may be more challenging to install but are necessary to ensure long-term reliability and safety in demanding environments.

Making the Right Choice for Your Application

Use your primary operational goal to guide your selection process, balancing convenience with the non-negotiable performance requirements.

- If your primary focus is reliability in a harsh chemical or high-temperature environment: Prioritize the packing's chemical and thermal ratings above all else; installation ease is a secondary benefit.

- If your primary focus is reducing downtime on standard equipment: Seek out packing designs engineered for easy installation, but only after confirming they meet all baseline operational requirements for your system.

- If your primary focus is compliance for food or pharmaceuticals: First, ensure the packing is FDA-approved and will not bleed color, then evaluate its performance ratings and installation process.

By correctly prioritizing these factors, you ensure that operational efficiency is built upon a foundation of uncompromised reliability and safety.

Summary Table:

| Factor | Priority | Key Consideration |

|---|---|---|

| Chemical & Thermal Resistance | Non-Negotiable | Must withstand specific process fluids and temperatures. |

| Pressure & Mechanical Stress | High | Must handle system pressure without extruding or failing. |

| Ease of Installation | Secondary | Reduces downtime and labor costs, but only after core needs are met. |

Need a PTFE Packing Solution That Balances Performance and Ease of Installation?

At KINTEK, we manufacture high-performance PTFE components—including seals, packings, and liners—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a solution that meets your exact chemical, thermal, and pressure requirements, while also considering installation efficiency to minimize your downtime.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders.

Contact KINTEK today for a reliable, application-engineered PTFE packing solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components