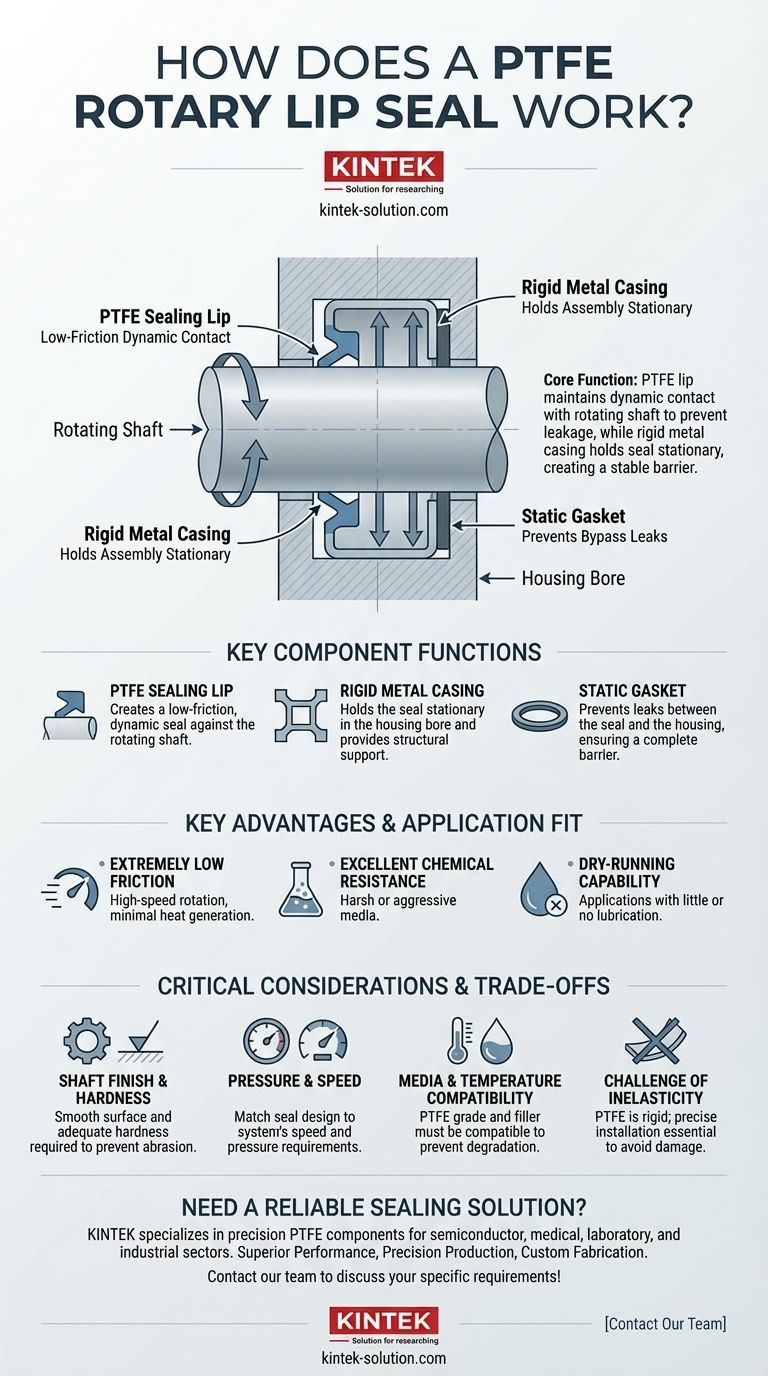

At its core, a PTFE rotary lip seal works by using a precision-engineered PTFE (polytetrafluoroethylene) lip to maintain dynamic contact with a rotating shaft. This lip prevents leakage, while a rigid outer metal casing holds the entire seal assembly stationary within a housing bore, creating a stable and highly effective barrier between two environments.

The fundamental principle is not just sealing, but sealing with minimal friction. The unique properties of PTFE allow the lip to glide smoothly over the shaft, generating very little heat and wear even at high speeds or without lubrication, making it ideal for demanding applications where traditional rubber seals would fail.

How PTFE Achieves a Superior Seal

The effectiveness of a PTFE rotary lip seal is not accidental; it is a direct result of the material's inherent properties and the seal's specific design.

The Low-Friction Sealing Lip

The primary sealing element is the lip, made from a filled or unfilled PTFE compound. Unlike rubber, which requires a thin film of lubricant to function, PTFE has an extremely low coefficient of friction.

This allows the lip to run directly against the shaft with minimal drag. This characteristic is critical for high-speed applications, as it significantly reduces heat generation and premature wear.

The Rigid Metal Casing

The PTFE lip is bonded to a metal casing, typically made of stainless steel or carbon steel. This casing serves a vital structural purpose.

It provides a robust press-fit into the stationary housing bore. This rigid installation prevents the seal from rotating with the shaft and ensures the sealing lip remains correctly oriented and loaded.

The Static Gasket

To prevent leaks from bypassing the seal through the press-fit interface, a gasket is often included between the PTFE element and the metal case.

This gasket creates a static seal against the housing, ensuring that the only path for fluid is blocked by the dynamic lip on the shaft.

Key Operational Considerations

A PTFE seal's performance is highly dependent on the system it is installed in. Ignoring these factors is a common cause of premature failure.

Shaft Surface Finish and Hardness

Because the PTFE lip runs directly on the shaft, the shaft's condition is paramount. It must have a very smooth surface finish and adequate hardness to resist abrasion over millions of rotations.

A rough or soft shaft will quickly wear down the sealing lip, leading to leaks.

Pressure and Speed

PTFE seals excel in high-speed, moderate-pressure scenarios. The design of the lip can be modified to handle higher pressures, often with the addition of a spring-energizer to increase the sealing force.

It's critical to match the seal's specific design profile to the system's speed and pressure requirements.

Media and Temperature Compatibility

PTFE is known for its excellent chemical resistance and ability to withstand a wide range of temperatures.

However, the specific grade of PTFE and any filler materials used must be compatible with the system's fluid or gas to prevent degradation of the sealing element.

Understanding the Trade-offs

While highly effective, PTFE seals have specific characteristics that must be managed, primarily stemming from the material's nature.

The Challenge of Inelasticity

The most significant difference between PTFE and traditional elastomers like rubber is its lack of elasticity. PTFE is a rigid polymer.

This means it will not snap back into place if deformed during installation. Careless handling can easily damage the precision sealing lip, rendering the entire seal useless.

The Need for Precise Installation

Due to this rigidity, proper installation tools and procedures are not just recommended; they are essential. The seal must be pressed into its housing squarely and without distorting the metal case.

Likewise, the shaft must be guided carefully through the seal's inner diameter to avoid nicking or folding the lip.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its capabilities to your primary operational goal.

- If your primary focus is high-speed rotation: Choose a PTFE lip seal specifically for its low-friction properties, which minimize heat buildup and allow for speeds that would burn up a standard rubber seal.

- If your primary focus is chemical compatibility: Select a PTFE seal when dealing with aggressive chemicals or fluids that would degrade traditional elastomers.

- If your primary focus is dry-running capability: A PTFE seal is the definitive choice for applications where lubrication is inconsistent or entirely absent.

Ultimately, a PTFE rotary lip seal is an engineered solution for problems that cannot be solved by conventional means.

Summary Table:

| Key Component | Primary Function |

|---|---|

| PTFE Sealing Lip | Creates a low-friction, dynamic seal against the rotating shaft. |

| Rigid Metal Casing | Holds the seal stationary in the housing bore and provides structural support. |

| Static Gasket | Prevents leaks between the seal and the housing, ensuring a complete barrier. |

| Key Advantage | Application Fit |

| Extremely Low Friction | High-speed rotation, minimal heat generation. |

| Excellent Chemical Resistance | Harsh or aggressive media. |

| Dry-Running Capability | Applications with little or no lubrication. |

Need a Reliable Sealing Solution for Your Critical Equipment?

PTFE seals are engineered for performance where standard seals fail. KINTEK specializes in manufacturing precision PTFE components, including custom rotary lip seals, for the semiconductor, medical, laboratory, and industrial sectors.

We deliver:

- Superior Performance: Seals designed for high speeds, harsh chemicals, and extreme temperatures.

- Precision Production: Consistent quality and reliability for your most demanding applications.

- Custom Fabrication: From prototype development to high-volume production runs.

Let our expertise solve your toughest sealing challenges. Contact our team today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance