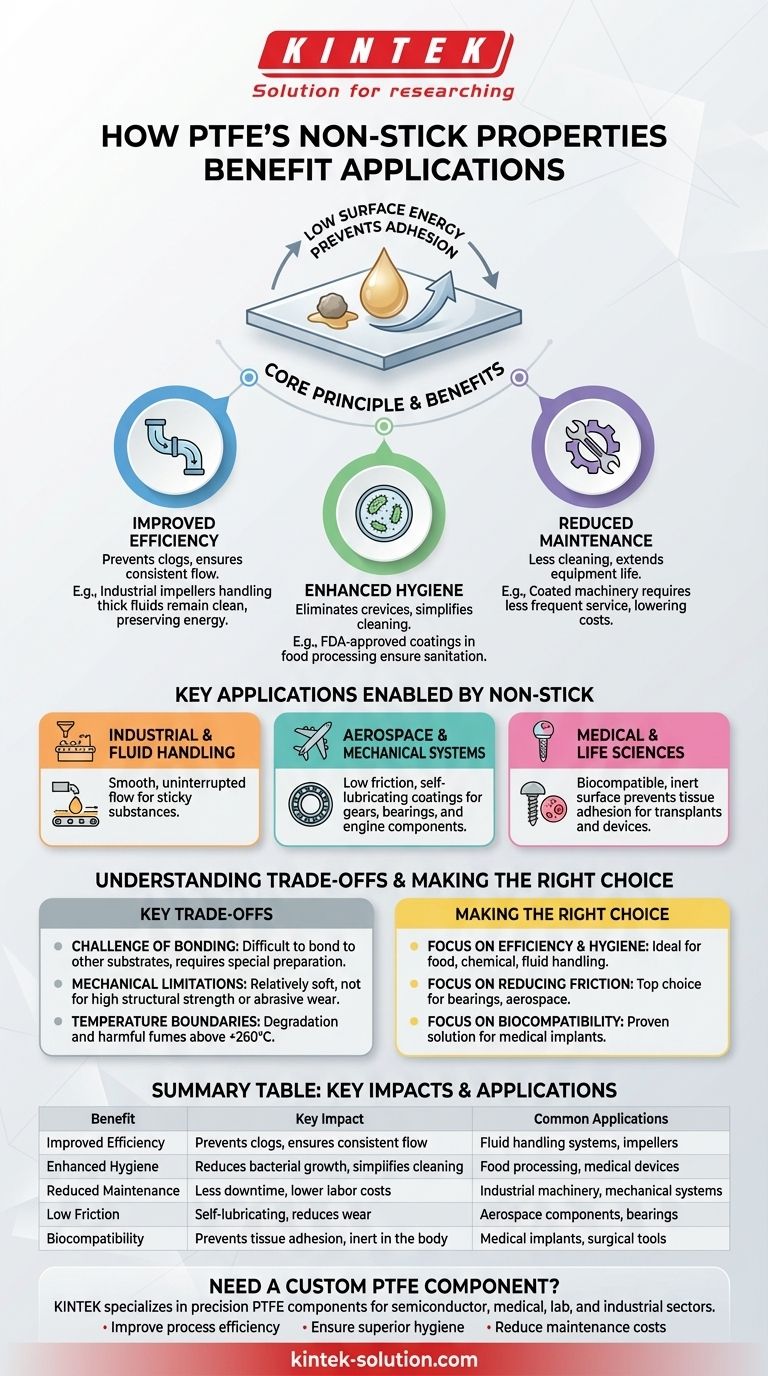

At its core, the non-stick property of Polytetrafluoroethylene (PTFE) prevents other materials from adhering to its surface. This single characteristic delivers significant operational benefits, including improved efficiency, enhanced hygiene, and drastically reduced maintenance across industrial, consumer, and medical applications.

The true value of PTFE's non-stick surface is not just convenience; it is a fundamental engineering advantage that reduces friction and prevents material buildup, ensuring cleaner, more reliable performance in demanding environments.

The Core Principle: Preventing Material Buildup

PTFE's non-stick nature is a direct result of its unique molecular structure, which creates an incredibly low-energy surface that other substances cannot easily bond with. This has direct and powerful implications.

The Impact on Efficiency

When materials, especially sticky or viscous ones, flow over a PTFE surface, they move without resistance or accumulation. This prevents clogs and maintains consistent operational speed.

For example, on industrial impellers handling thick fluids, a PTFE coating ensures the blades remain clean and balanced, preserving efficiency and preventing system strain.

The Advantage in Hygiene

In food processing and medical applications, a surface that resists buildup is inherently more hygienic. It eliminates crevices and residues where bacteria could otherwise grow.

This is why PTFE is used for FDA-approved coatings in applications like pet food production, as it simplifies cleaning and ensures a higher standard of sanitation.

The Reduction in Maintenance

Preventing buildup directly translates to less cleaning and downtime. Equipment coated with PTFE requires far less frequent and intensive maintenance to keep it in optimal working condition.

This reduces labor costs, extends the life of machinery, and increases overall productivity by keeping systems online for longer periods.

How "Non-Stick" Enables Key Applications

While commonly associated with cookware, PTFE's non-stick characteristic is a critical enabler in highly technical fields, often working in tandem with its other extreme-performance properties.

Industrial and Fluid Handling

In manufacturing, PTFE coatings are essential for handling sticky substances. The material's ability to prevent adhesion ensures a smooth, uninterrupted flow, which is vital for process efficiency.

Aerospace and Mechanical Systems

Here, the "non-stick" quality is better described as a low coefficient of friction. PTFE's self-lubricating surface is used to coat gears, bearings, and engine components.

This reduces wear on friction-prone parts and, combined with its high-temperature resistance and light weight, helps improve the durability and fuel efficiency of aircraft.

Medical and Life Sciences

PTFE is highly biocompatible, meaning it does not react with bodily tissues. Its inert, non-stick surface is crucial for medical transplants and devices.

This quality prevents blood cells or tissue from adhering to the implant, ensuring it functions correctly within the body without causing adverse reactions.

Understanding the Key Trade-offs

While its non-stick property is a powerful asset, it is essential to understand its context and limitations for proper material selection.

The Challenge of Bonding

The very property that prevents materials from sticking to PTFE also makes it notoriously difficult to bond PTFE to other substrates. This often requires complex chemical etching or other surface preparation techniques.

Mechanical Limitations

PTFE is a relatively soft material. While excellent for low-friction surfaces, it is not suitable for applications requiring high structural strength or resistance to abrasive wear on its own. Coatings can wear down over time with repeated physical contact.

Temperature Boundaries

PTFE has an exceptionally wide operating temperature range (from -200°C to +260°C). However, exceeding its upper limit can cause the material to degrade, releasing potentially harmful fumes.

Making the Right Choice for Your Goal

Selecting a material requires aligning its properties with your primary objective. PTFE's non-stick surface offers distinct advantages for specific goals.

- If your primary focus is process efficiency and hygiene: PTFE's ability to prevent buildup is ideal for food, chemical, or fluid handling systems.

- If your primary focus is reducing friction and wear: Its self-lubricating quality is a top-tier choice for bearings and coatings in mechanical and aerospace systems.

- If your primary focus is biocompatibility: Its inert, non-stick surface is a proven solution for medical devices and implants where preventing tissue adhesion is paramount.

Ultimately, PTFE's non-stick property is a powerful engineering tool that solves critical challenges of adhesion, friction, and contamination across the world's most demanding industries.

Summary Table:

| Benefit | Key Impact | Common Applications |

|---|---|---|

| Improved Efficiency | Prevents clogs, ensures consistent flow | Fluid handling systems, impellers |

| Enhanced Hygiene | Reduces bacterial growth, simplifies cleaning | Food processing, medical devices |

| Reduced Maintenance | Less downtime, lower labor costs | Industrial machinery, mechanical systems |

| Low Friction | Self-lubricating, reduces wear | Aerospace components, bearings |

| Biocompatibility | Prevents tissue adhesion, inert in the body | Medical implants, surgical tools |

Need a custom PTFE component that leverages these non-stick benefits?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We can help you:

- Improve process efficiency by preventing material buildup.

- Ensure superior hygiene with easy-to-clean, FDA-compliant surfaces.

- Reduce maintenance costs with durable, low-friction parts.

From prototypes to high-volume orders, our custom fabrication ensures your application performs reliably. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability