In the automotive industry, Teflon bushes are prized for their ability to significantly reduce friction and resist wear in critical moving parts. They are most commonly found in high-stress applications like suspension systems, gear assemblies, and brake components where durability and consistent performance are non-negotiable.

The core benefit of Teflon is not a single property, but its unique combination of near-zero friction, extreme temperature tolerance, and chemical inertness. This allows it to function as a self-lubricating, highly durable barrier that protects and enhances the performance of components in the harshest automotive environments.

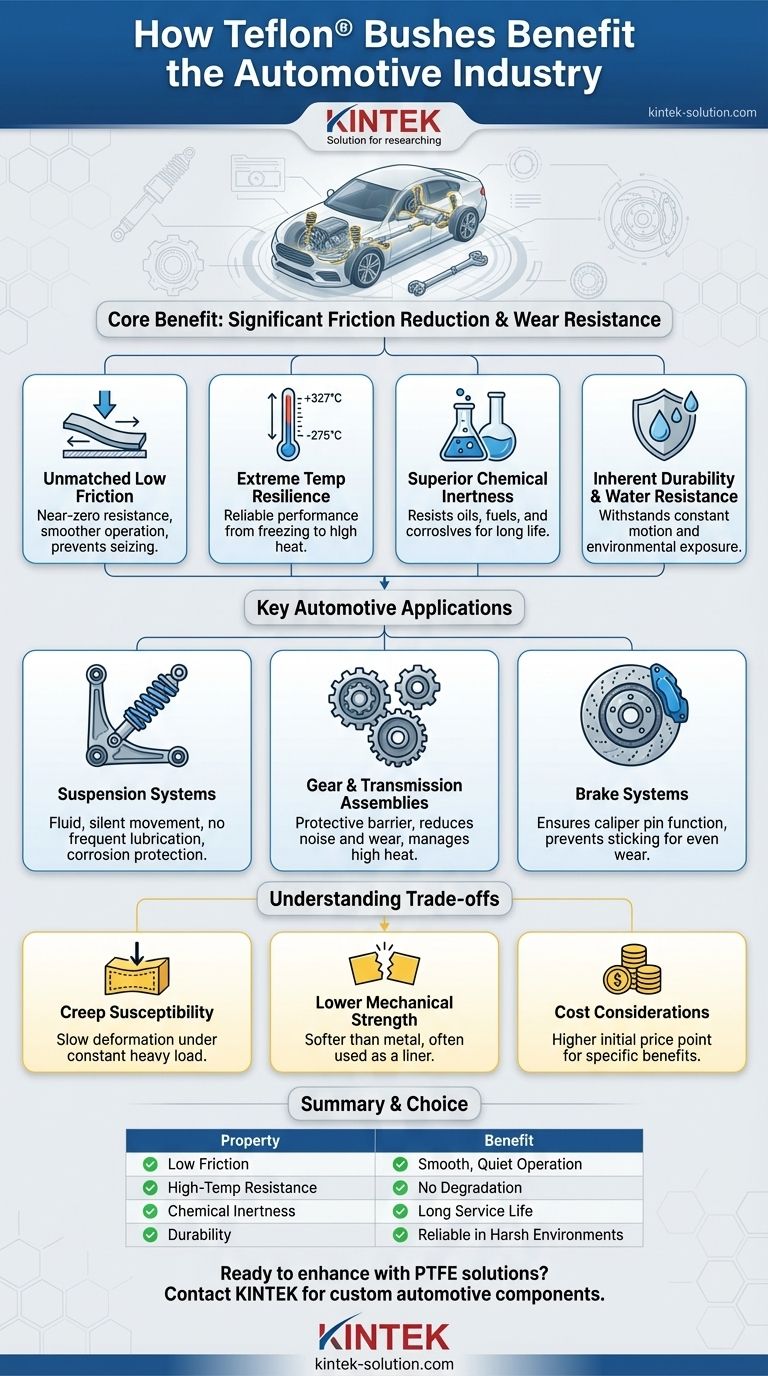

The Core Properties Driving Automotive Adoption

To understand why Teflon (PTFE) is so effective, we must look at its fundamental material characteristics. These properties solve some of the most persistent engineering challenges in vehicle design: friction, heat, and corrosion.

Unmatched Low Friction

Teflon possesses one of the lowest coefficients of friction of any solid material. This "non-stick" quality is its most famous attribute.

In an automotive context, this means that parts can move against each other with minimal resistance. This reduces the energy required for movement, prevents seizing, and ensures smoother, quieter operation.

Extreme Temperature Resilience

Automotive components operate in a wide range of temperatures, from freezing cold starts to the intense heat of the engine and brake systems.

Teflon performs reliably in temperatures up to 327°C (620°F) and as low as -275°C (-463°F). This thermal stability ensures that the bushing will not degrade, melt, or become brittle under normal or even extreme operating conditions.

Superior Chemical Inertness

A vehicle is a chemically hostile environment, filled with gasoline, motor oil, brake fluid, coolants, and external corrosives like road salt.

Teflon is chemically inert, meaning it does not react with these substances. This resistance prevents the material from degrading, swelling, or corroding, ensuring a long and predictable service life.

Inherent Durability and Water Resistance

Teflon's durable, wear-resistant nature means it can withstand constant motion and pressure without breaking down quickly.

It also resists water and weather, making it an excellent choice for externally-facing components like suspension parts, which are constantly exposed to the elements.

Where These Benefits Matter Most: Key Applications

The unique properties of Teflon translate directly into improved performance and reliability in specific automotive systems.

In Suspension Systems

Suspension components must pivot and move smoothly to absorb bumps and maintain tire contact with the road.

Teflon bushes here allow for fluid, silent movement without the need for frequent lubrication. Their resistance to water and road salt prevents the corrosion that can seize traditional metal-on-metal joints.

In Gear and Transmission Assemblies

Gears are under constant stress and friction. Teflon bushes or coatings act as a protective barrier between moving metal parts.

This reduces operational noise, minimizes wear, and helps manage the high temperatures generated within a gearbox, extending the life of the entire assembly.

In Brake Systems

Brake systems generate immense heat during operation. Teflon's high-temperature resistance ensures that components like caliper pin bushings continue to function correctly.

This prevents the pins from sticking, which could otherwise lead to uneven brake pad wear and reduced braking performance.

Understanding the Trade-offs

While highly effective, Teflon is not a universal solution. An objective analysis requires acknowledging its limitations.

Susceptibility to Creep

Under a constant, heavy load, Teflon can slowly deform over time—a phenomenon known as "creep." Engineers must account for this in designs where precise tolerances are critical over the vehicle's entire lifespan.

Lower Mechanical Strength

Compared to bronze or steel, Teflon is a much softer material. It is not suitable for applications requiring high structural or impact strength. For this reason, it is often used as a liner within a stronger metal housing.

Cost Considerations

High-performance materials often come at a higher price point. Teflon bushes can be more expensive than their traditional nylon or rubber counterparts, making them a choice reserved for applications where their specific benefits justify the cost.

Making the Right Choice for Your Goal

Selecting the right material always depends on the primary objective of the component's design.

- If your primary focus is maintenance-free, smooth operation: Teflon is the ideal choice due to its self-lubricating, low-friction properties that eliminate the need for grease.

- If your primary focus is longevity in harsh environments: Teflon's unmatched chemical and thermal resistance makes it superior for parts exposed to corrosive fluids and extreme heat.

- If your primary focus is managing high structural loads on a tight budget: A traditional bronze bushing or a reinforced polymer composite may be a more appropriate choice.

Ultimately, leveraging Teflon's unique properties allows engineers to build more resilient, efficient, and reliable automotive systems.

Summary Table:

| Property | Benefit for Automotive Applications |

|---|---|

| Low Friction | Reduces wear, prevents seizing, and ensures smooth, quiet operation. |

| High-Temp Resistance | Withstands extreme heat from engines and brakes without degrading. |

| Chemical Inertness | Resists degradation from oils, fuels, and road salts for long service life. |

| Durability & Water Resistance | Performs reliably in harsh, exposed environments like suspension systems. |

Ready to enhance your automotive components with high-performance PTFE solutions?

KINTEK specializes in manufacturing precision PTFE components, including custom bushes, seals, and liners for the demanding automotive industry. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get parts that deliver superior friction reduction, thermal stability, and chemical resistance.

Contact our experts today to discuss how our PTFE solutions can improve the performance and longevity of your automotive systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support