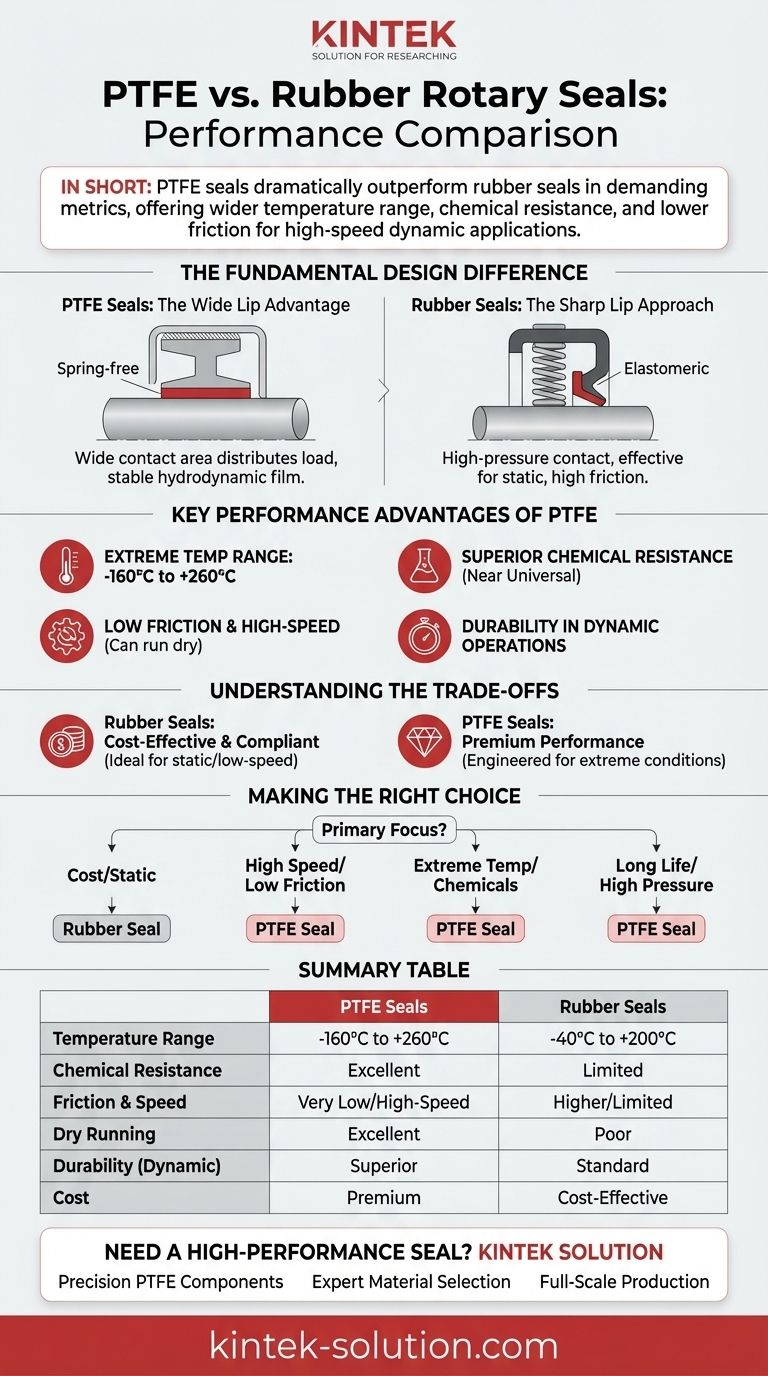

In short, PTFE rotary seals dramatically outperform rubber seals in nearly every demanding performance metric. PTFE offers a far wider operating temperature range (–160°C to +260°C), near-universal chemical resistance, and significantly lower friction, making it ideal for high-speed, dynamic applications where rubber seals would quickly fail.

The choice between PTFE and rubber is not about which material is universally "better," but which is engineered for the specific task. Rubber seals are a cost-effective standard for general-purpose, static applications, while PTFE seals are a high-performance solution designed explicitly for extreme operating conditions.

The Fundamental Design Difference

The performance gap between these two seal types is rooted in their core design philosophy. Each is engineered to solve a different type of sealing problem.

Rubber Seals: The Sharp Lip Approach

Traditional rubber oil seals rely on the material's elasticity. They typically use a spring to compress a sharp, narrow sealing lip against the shaft.

This design creates a high-pressure line of contact, which is effective for static sealing but generates significant friction and heat in dynamic, high-speed applications.

PTFE Seals: The Wide Lip Advantage

PTFE seals utilize a spring-free, wide lip dynamic structure. The contact surface is often 10 to 20 times wider than that of a comparable rubber seal.

This wide contact area distributes the load, maintains a more stable hydrodynamic oil film, and is far less sensitive to shaft runout or eccentricity. This design is inherently more stable and durable for rotary motion.

Key Performance Advantages of PTFE

The material properties of Polytetrafluoroethylene (PTFE) combined with its unique design give it a distinct edge in demanding environments.

Extreme Temperature Range

PTFE seals function reliably in temperatures from –160°C to +260°C. This vastly exceeds the capabilities of most elastomeric (rubber) seals, which are typically limited to a range of –40°C to +200°C.

Superior Chemical Resistance

PTFE is one of the most chemically inert materials used in industry. It provides excellent resistance against aggressive chemicals, solvents, and abrasive media that would degrade rubber seals.

Low Friction and High-Speed Capability

PTFE has an exceptionally low coefficient of friction. This translates to less heat generation, reduced power loss, and the ability to operate at much higher rotational speeds without premature wear.

Crucially, this also allows PTFE seals to run dry for periods without damage, a condition that would destroy a rubber seal almost instantly.

Durability in Dynamic Operations

The combination of low friction, a stable wide lip, and material toughness makes PTFE seals exceptionally durable. They are the preferred choice for applications involving high pressure, long life requirements, and continuous dynamic motion.

Understanding the Trade-offs

While PTFE excels in performance, rubber seals remain the standard for many applications for valid reasons. Their limitations in extreme conditions are balanced by practicality in less demanding roles.

Cost-Effectiveness

For simple, high-volume, or less critical applications, rubber seals are significantly more cost-effective. PTFE is a premium material, and its manufacturing is a more specialized process.

Compliance and Forgiveness

The inherent elasticity of rubber allows it to conform well to minor surface imperfections in static or low-speed applications. It can provide a reliable seal where high-precision surface finishes are not practical.

Simplicity in Static Sealing

In applications with no movement (static sealing), the high-performance dynamic characteristics of PTFE are unnecessary. A traditional rubber O-ring or gasket is often the simpler, more economical, and perfectly adequate solution.

Making the Right Choice for Your Application

Selecting the correct seal requires a clear understanding of your system's operating demands.

- If your primary focus is cost-effectiveness for standard, static sealing: A rubber seal is almost always the correct and most economical choice.

- If your primary focus is high rotational speed, low friction, or potential dry running: The low-friction and durable nature of PTFE is a strict requirement.

- If your primary focus is extreme temperatures or aggressive chemical exposure: PTFE's material stability is the only viable option for long-term reliability.

- If your primary focus is long life in a high-pressure dynamic system: The wide-lip design and wear resistance of a PTFE seal will provide superior performance.

Ultimately, choosing the right seal is a matter of matching the material's engineered capabilities to the precise demands of your operating environment.

Summary Table:

| Performance Metric | PTFE Seals | Rubber Seals |

|---|---|---|

| Temperature Range | –160°C to +260°C | –40°C to +200°C |

| Chemical Resistance | Excellent (Near Universal) | Limited |

| Friction & Speed | Very Low / High-Speed Capable | Higher / Limited Speed |

| Dry Running Capability | Excellent | Poor |

| Durability (Dynamic) | Superior | Standard |

| Cost | Premium | Cost-Effective |

Need a High-Performance Seal for Demanding Conditions?

Your application's success depends on selecting the right sealing solution. For high-speed, high-temperature, or chemically aggressive environments, PTFE seals from KINTEK are the engineered answer.

We provide:

- Precision PTFE Components: Custom-fabricated seals, liners, and labware.

- Expert Material Selection: Guidance to ensure optimal performance for your specific needs in the semiconductor, medical, laboratory, and industrial sectors.

- Full-Scale Production: From prototypes to high-volume orders, we deliver the quality and reliability your operations demand.

Let's engineer the perfect seal for your challenge. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials