At their core, Polytetrafluoroethylene (PTFE) lip seals contribute to industrial machinery efficiency by fundamentally reducing energy waste and operational downtime. Their unique material properties allow machinery to operate at higher speeds and temperatures with significantly less friction than traditional rubber seals, leading to enhanced productivity and extended component life.

The primary advantage of PTFE lip seals is their ability to attack inefficiency on multiple fronts: they cut direct energy consumption by minimizing friction, reduce maintenance costs through superior durability, and increase output by enabling more demanding operational parameters.

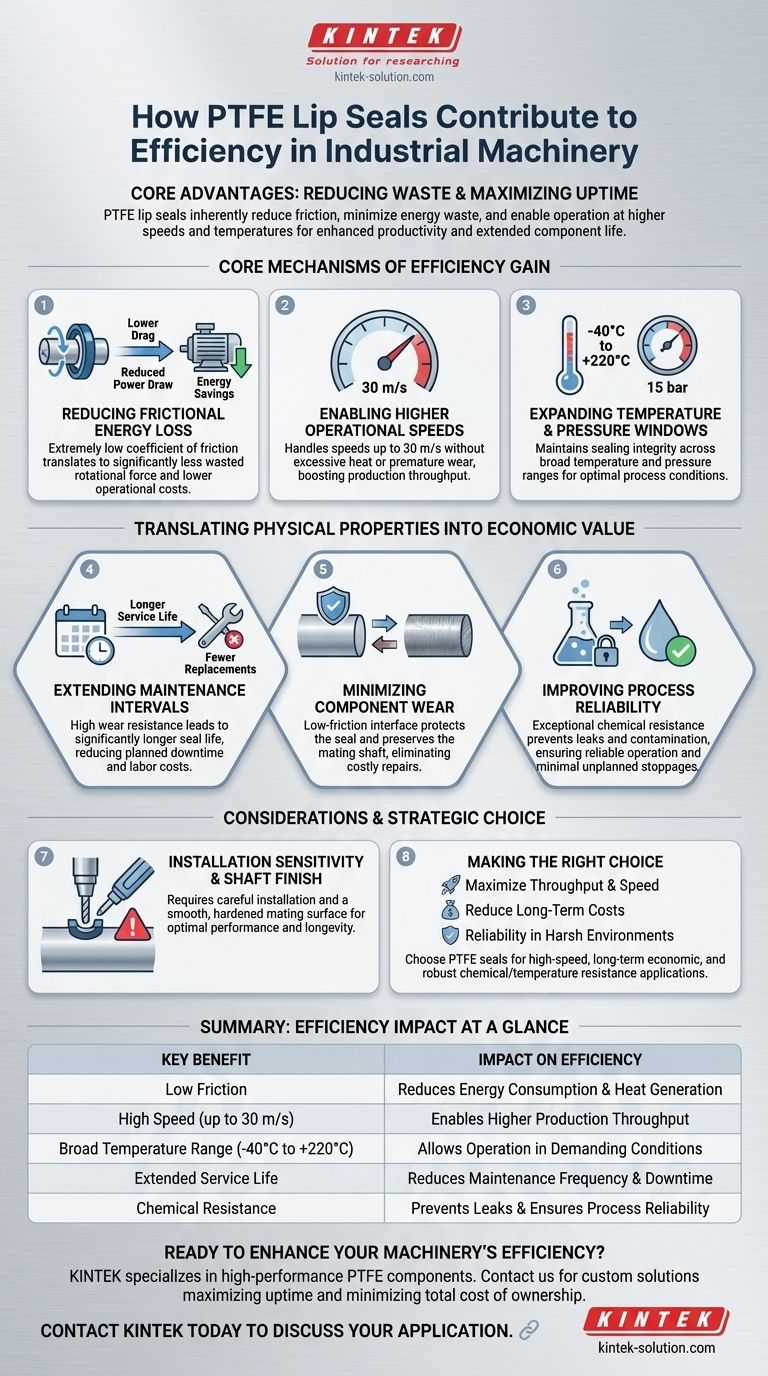

The Core Mechanisms of Efficiency Gain

Understanding how PTFE seals deliver these benefits requires looking at their fundamental physical properties and how they perform under stress.

Reducing Frictional Energy Loss

The defining characteristic of PTFE is its extremely low coefficient of friction. In a dynamic sealing application, this translates directly into reduced energy consumption.

Less rotational force is wasted overcoming the drag between the seal lip and the shaft. This allows the machine's motor to operate more efficiently, lowering power draw and reducing operational costs over the equipment's lifespan.

Enabling Higher Operational Speeds

Traditional elastomeric (rubber) seals can generate significant heat from friction at high rotational speeds, leading to premature wear and failure.

PTFE's low-friction nature and high temperature tolerance allow it to handle shaft speeds of up to 30 m/s. This enables machinery to run faster and achieve higher production throughput without compromising seal integrity.

Expanding Temperature and Pressure Windows

Efficiency is often found at the limits of operational parameters. PTFE seals excel in these demanding environments.

They maintain their sealing capability across a broad temperature range, typically from -40°C to +220°C. This stability, combined with pressure resistance up to 15 bar, allows processes to run under optimal conditions that might degrade lesser materials.

Translating Physical Properties into Economic Value

The technical advantages of PTFE seals create tangible economic benefits by shifting focus from frequent replacement to long-term reliability.

Extending Maintenance Intervals

Due to their high wear resistance, PTFE seals last significantly longer than many traditional alternatives. This directly reduces the frequency of planned downtime for seal replacement.

The result is more machine uptime, lower labor costs for maintenance, and reduced inventory costs for spare parts. Manufacturers often leverage this by offering extended warranties on equipment fitted with PTFE seals.

Minimizing Component Wear

The low-friction interface is a two-way benefit. While protecting the seal from wear, it also preserves the surface of the shaft it runs against.

This eliminates the costly and time-consuming need to re-machine or replace worn shafts, which is a common failure point in systems using more abrasive seal materials.

Improving Process Reliability

PTFE's exceptional chemical resistance ensures it is not degraded by aggressive lubricants or process fluids.

This material integrity prevents leaks and contamination, ensuring the machinery operates reliably with minimal unplanned downtime. This is particularly critical in applications where seal failure could lead to significant production losses or safety hazards.

Understanding the Trade-offs and Considerations

While highly effective, achieving optimal performance with PTFE seals requires acknowledging their specific characteristics. They are an engineered solution, not a universal drop-in replacement.

Installation Sensitivity

PTFE is a more rigid material than traditional elastomers. This means installation requires greater care and proper tooling to avoid damaging the seal lip. Unlike a flexible rubber seal, a PTFE seal will not simply "snap" back if mishandled.

Shaft Finish Requirements

To leverage the low-friction properties of PTFE, the mating shaft surface must meet specific requirements. A smooth, hardened surface is typically necessary to prevent abrasion and ensure a long service life for the seal.

Initial Cost vs. Total Cost of Ownership

The upfront cost of a PTFE seal may be higher than a standard rubber seal. However, this initial investment is almost always offset by a lower total cost of ownership when factoring in reduced energy consumption, longer life, and minimized downtime.

Making the Right Choice for Your Application

Selecting the right seal is a strategic decision based on your primary operational goals.

- If your primary focus is maximizing throughput and speed: The high-speed and high-temperature capabilities of PTFE seals are unmatched for pushing machinery to its production limits.

- If your primary focus is reducing long-term operational costs: The combined benefits of energy savings, extended maintenance intervals, and reduced shaft wear make PTFE the superior economic choice.

- If your primary focus is reliability in harsh environments: PTFE's broad chemical and temperature resistance provides a robust sealing solution where other materials would quickly fail.

Ultimately, integrating PTFE lip seals is an investment in your machinery's long-term efficiency and reliability.

Summary Table:

| Key Benefit | Impact on Efficiency |

|---|---|

| Low Friction | Reduces energy consumption & heat generation |

| High Speed (up to 30 m/s) | Enables higher production throughput |

| Broad Temperature Range (-40°C to +220°C) | Allows operation in demanding conditions |

| Extended Service Life | Reduces maintenance frequency & downtime |

| Chemical Resistance | Prevents leaks and ensures process reliability |

Ready to enhance your machinery's efficiency and reliability?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including lip seals, for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services—from prototypes to high-volume orders—ensure you get a sealing solution tailored to your specific operational demands, maximizing uptime and minimizing your total cost of ownership.

Contact KINTEK today to discuss your application and discover the right PTFE seal for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support