In short, PTFE liners improve minimally invasive procedures by creating an incredibly smooth, low-friction internal surface for medical devices. This allows instruments to be guided through complex anatomical pathways with minimal force, which directly reduces internal tissue trauma, enhances surgeon control, and improves patient safety. Their inherent durability and biocompatibility are critical supporting properties that ensure the device is both reliable and safe for internal use.

The core function of a PTFE liner is to fundamentally change the interaction between a medical device and the body's delicate internal structures. It transforms a potentially high-friction, traumatic event into a smooth, controlled, and significantly safer intervention.

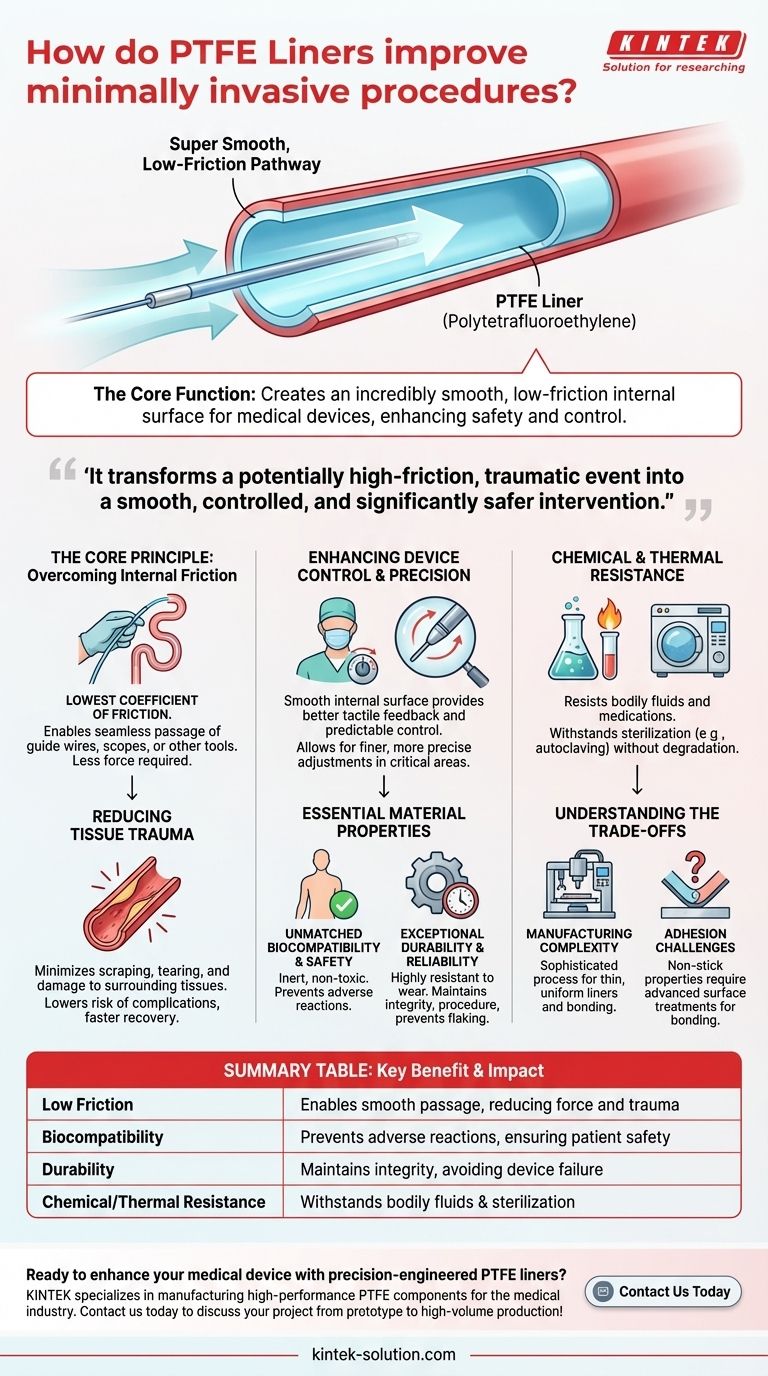

The Core Principle: Overcoming Internal Friction

In any minimally invasive procedure, from cardiovascular interventions to endoscopies, a primary challenge is navigating a device through the body. The internal surfaces of catheters and other instruments must allow for the seamless passage of guide wires, scopes, or other tools.

The Critical Role of a Low-Friction Surface

PTFE (Polytetrafluoroethylene) has one of the lowest coefficients of friction of any solid material. When used as a liner, it creates an exceptionally slick pathway.

This property is not merely an enhancement; it is an enabler. It allows surgeons to advance and retract instruments with minimal resistance, which is crucial when navigating tortuous blood vessels or other delicate passages.

Reducing Tissue Trauma

Less friction means less force is required to operate the device. This reduction in force translates directly to less scraping, tearing, and damage to the surrounding tissues and vessel walls.

The result is a significant decrease in patient discomfort, reduced risk of complications like perforations, and faster post-operative recovery times.

Enhancing Device Control and Precision

A smooth, consistent internal surface gives the physician better tactile feedback and more predictable control.

When an instrument moves without sticking or jerking, the surgeon can make finer, more precise adjustments. This level of control is paramount for the success of complex procedures performed in small, critical areas of the body.

Essential Material Properties for Clinical Success

While low friction is the primary benefit, several other intrinsic properties of PTFE make it the ideal material for this application. These are not secondary benefits but necessary conditions for its use in medicine.

Unmatched Biocompatibility and Safety

Biocompatibility means the material is inert and will not cause an adverse or toxic reaction when introduced into the body. PTFE is exceptionally biocompatible, making it a trusted material for internal medical devices.

This ensures that the liner itself does not pose a risk to the patient, which is a non-negotiable requirement for any implantable or invasive medical component.

Exceptional Durability and Reliability

Medical devices must perform flawlessly from the beginning of a procedure to the end. PTFE is highly resistant to wear and tear.

A PTFE liner maintains its integrity and low-friction properties throughout the intervention, preventing dangerous situations like material flaking or delamination inside the body.

Chemical and Thermal Resistance

The human body is a chemically active environment. PTFE is resistant to nearly all chemicals and solvents, ensuring it will not degrade upon contact with bodily fluids or administered medications.

Furthermore, its resistance to extreme temperatures means it can withstand common sterilization methods, like autoclaving, without compromising its structural integrity.

Understanding the Trade-offs

While PTFE is a superior material for liners, it's important to understand the context of its application. No material is without practical considerations.

Manufacturing Complexity

Creating extremely thin, uniform PTFE liners and bonding them to the interior of complex medical devices like multi-lumen catheters is a sophisticated manufacturing process.

This process requires specialized expertise and equipment, which can influence the cost and design of the final medical device.

Adhesion Challenges

The same non-stick properties that make PTFE so valuable also make it difficult to bond to other materials.

Device manufacturers must employ advanced surface treatment techniques (like chemical etching) to ensure the liner remains securely affixed to the catheter or instrument body.

How PTFE Liners Drive Procedural Innovation

The selection of a PTFE liner is a decision based on the fundamental requirements of a procedure. Its properties directly enable specific clinical goals.

- If your primary focus is patient safety and outcomes: The liner's combination of low friction and biocompatibility is the key, directly minimizing tissue damage and the risk of adverse reactions.

- If your primary focus is device performance and reliability: The material's durability, non-stick surface, and chemical resistance ensure consistent, predictable operation from device insertion to removal.

- If your primary focus is enabling complex interventions: The ability to mold PTFE into intricate shapes for advanced catheters is what makes it possible to navigate to previously inaccessible anatomical sites.

Ultimately, the humble PTFE liner is a critical component that has quietly enabled the advancement of safer and more effective minimally invasive medicine.

Summary Table:

| Key Benefit | Impact on Minimally Invasive Procedures |

|---|---|

| Low Friction | Enables smooth instrument passage, reducing force and tissue trauma. |

| Biocompatibility | Prevents adverse reactions, ensuring patient safety. |

| Durability | Maintains integrity during procedures, avoiding device failure. |

| Chemical/Thermal Resistance | Withstands bodily fluids and sterilization (e.g., autoclaving). |

Ready to enhance your medical device with precision-engineered PTFE liners? KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, and labware—for the medical, semiconductor, and laboratory industries. Our custom fabrication ensures your devices achieve superior smoothness, reliability, and biocompatibility. Contact us today to discuss your project from prototype to high-volume production!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications