At their core, PTFE-lined butterfly valves minimize maintenance through a unique combination of material properties that prevent the most common causes of valve failure. The design leverages Polytetrafluoroethylene (PTFE) for its inherent self-lubrication, extreme chemical inertness, and non-stick surface. These characteristics work together to dramatically reduce internal friction, stop corrosion before it can start, and prevent media buildup, which directly translates to a longer service life with significantly less required upkeep.

Conventional valves often require frequent maintenance due to friction-induced wear, chemical corrosion, and internal clogging. A PTFE-lined butterfly valve addresses these failure points by design, isolating the valve's metal components from the process media while creating an inherently slick, low-friction environment for operation.

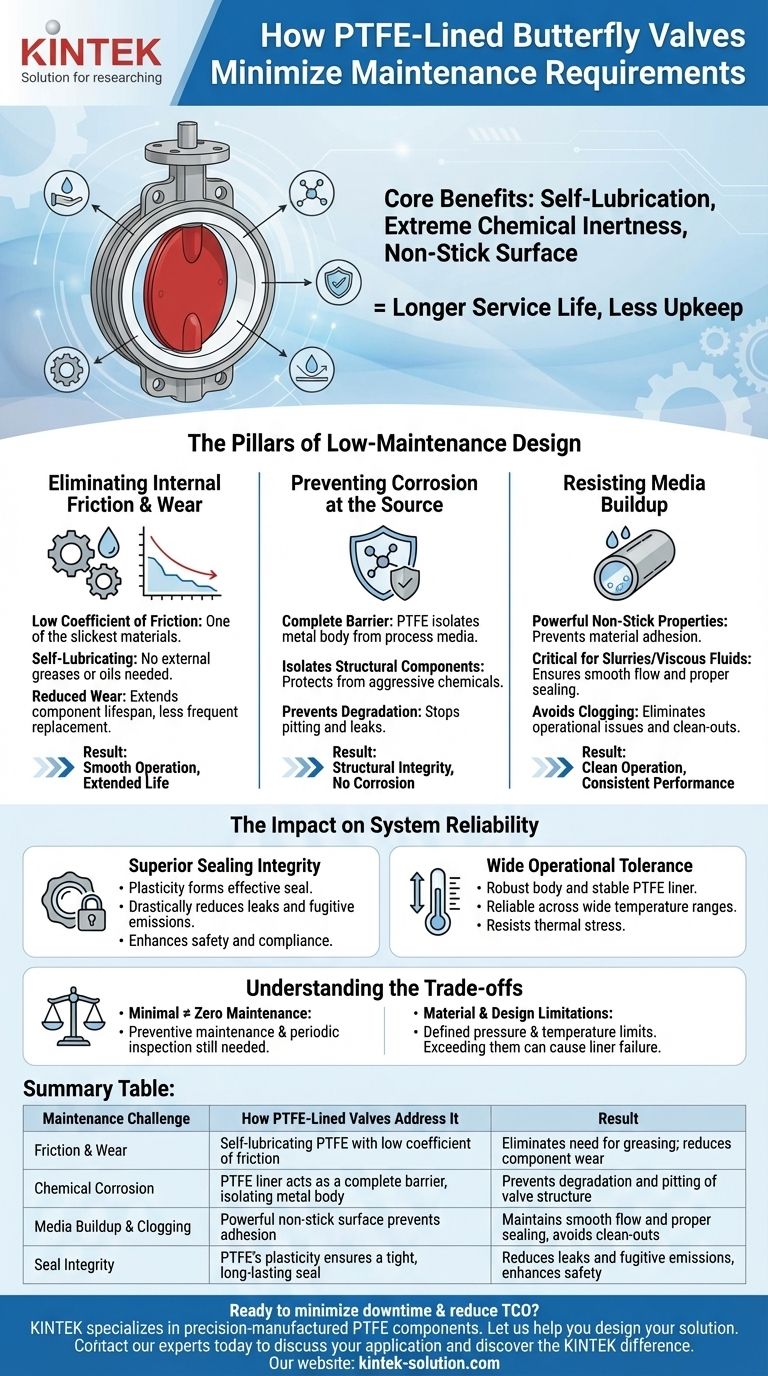

The Pillars of Low-Maintenance Design

The reliability of a PTFE-lined valve is not a single feature but the result of several core material properties working in concert. Understanding these pillars clarifies why this design is so robust in demanding environments.

Eliminating Internal Friction and Wear

PTFE possesses an extremely low coefficient of friction, making it one of the slickest materials known. This property is fundamental to the valve's longevity.

The material is self-lubricating, meaning there is no need for external greases or oils on the internal moving parts. This eliminates a common maintenance task entirely.

Reduced friction means less wear and tear on the valve disc, stem, and, most critically, the seat seals. This directly extends the operational lifespan and reduces the frequency of component replacement.

Preventing Corrosion at the Source

The primary function of the PTFE liner is to act as a complete, non-reactive barrier between the process media and the valve's metal body.

This design effectively isolates structural components, like stainless steel, from corrosive or aggressive chemicals. The media only ever touches the inert PTFE.

This prevents the gradual degradation and pitting that affects unlined metal valves, which is a leading cause of leaks and eventual failure.

Resisting Media Buildup

PTFE has powerful non-stick properties, preventing materials from adhering to the valve's internal surfaces.

This is especially critical in processes involving slurries, viscous fluids, or media that could otherwise crystallize or build up. A clean surface ensures the valve can close properly and maintains smooth flow.

By preventing internal clogging, the valve avoids the operational issues and required clean-outs that plague other valve types in similar applications.

The Impact on System Reliability

These material advantages translate directly into tangible operational benefits, primarily centered on creating a more predictable and reliable system.

Superior Sealing Integrity

The natural plasticity of PTFE allows it to form a highly effective, tight seal around the disc when the valve is closed.

This capability drastically reduces the risk of both internal system leaks and fugitive emissions to the atmosphere, enhancing safety and compliance.

Because the seal remains clean and is not subject to corrosive degradation, it maintains its integrity for far longer, minimizing the need for maintenance adjustments.

Wide Operational Tolerance

The combination of a robust metal body and a stable PTFE liner allows the valve to function reliably across a wide temperature range.

This thermal stability means the valve's performance and sealing capabilities do not degrade under fluctuating process conditions, reducing the risk of stress-related failures.

Understanding the Trade-offs

While highly effective, it is crucial to recognize that "minimal maintenance" does not mean "zero maintenance." Objectivity requires acknowledging the operational realities.

"Minimal" Does Not Mean "Zero"

Even with PTFE's durability, mechanical components like seals and actuators are subject to wear over many cycles.

Preventive maintenance and periodic inspection are still best practices, especially in critical service applications, to ensure long-term operational reliability and catch any potential issues before they cause downtime.

Material and Design Limitations

While the liner protects the valve body, the PTFE itself has defined pressure and temperature limits.

Exceeding the manufacturer's specified operational window can lead to liner damage or failure. It is essential to select a valve rated appropriately for the system's parameters to realize its low-maintenance benefits.

Making the Right Choice for Your System

Selecting the correct valve depends entirely on the specific demands of your process. A PTFE-lined butterfly valve excels where reliability and low intervention are paramount.

- If your primary focus is handling corrosive chemicals: The PTFE liner's complete chemical inertness is its greatest advantage, preventing valve body degradation and ensuring maximum service life.

- If your primary focus is reducing operational downtime: The self-lubricating and non-stick properties significantly lower the risk of the valve seizing or clogging, ensuring consistent reliability in difficult media.

- If your primary focus is lowering Total Cost of Ownership (TCO): The combined benefits of fewer replacement cycles, eliminated lubrication needs, and reduced labor for repairs make these valves a cost-effective choice over their entire lifespan.

By fundamentally designing out the root causes of wear and corrosion, PTFE-lined butterfly valves offer a highly reliable and efficient flow control solution for demanding applications.

Summary Table:

| Maintenance Challenge | How PTFE-Lined Valves Address It | Result |

|---|---|---|

| Friction & Wear | Self-lubricating PTFE with low coefficient of friction | Eliminates need for greasing; reduces component wear |

| Chemical Corrosion | PTFE liner acts as a complete barrier, isolating metal body | Prevents degradation and pitting of valve structure |

| Media Buildup & Clogging | Powerful non-stick surface prevents adhesion | Maintains smooth flow and proper sealing, avoids clean-outs |

| Seal Integrity | PTFE's plasticity ensures a tight, long-lasting seal | Reduces leaks and fugitive emissions, enhances safety |

Ready to minimize downtime and reduce your total cost of ownership?

KINTEK specializes in precision-manufactured PTFE components, including custom seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your valves and systems are built for maximum reliability and minimal maintenance.

Let us help you design a solution that fits your exact needs, from prototypes to high-volume production.

Contact our experts today to discuss your application and discover the KINTEK difference.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry