In short, PTFE-jacketed energized seals perform exceptionally well in demanding oil and gas environments. Their unique construction allows them to reliably handle the aggressive chemicals, extreme temperatures, and high pressures that are characteristic of the industry, from downhole tools to surface equipment.

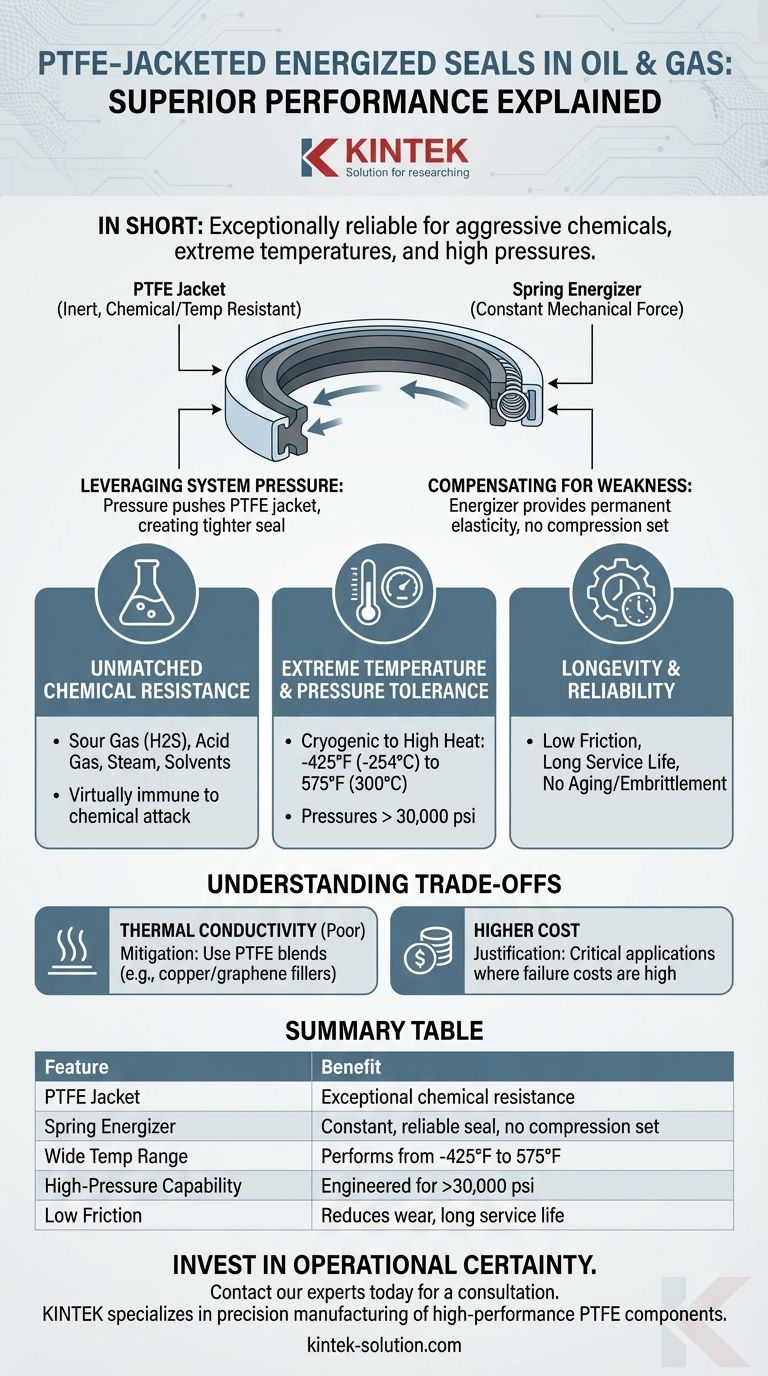

The core value of a PTFE energized seal lies in its two-part design: a nearly inert PTFE jacket provides chemical and temperature resistance, while an internal energizer (a spring or elastomer) provides the constant mechanical force needed to maintain a leak-tight barrier, even under fluctuating conditions.

How Energized Seals Achieve Superior Performance

The reliability of these seals comes from their intelligent engineering, which compensates for material limitations and leverages system physics to its advantage.

The Dual-Component Design

A PTFE energized seal is not a single material. It consists of a precision-machined PTFE jacket that makes contact with the hardware and a spring energizer (typically metal) or elastomeric O-ring that sits inside the jacket.

This design uses each component for what it does best. The PTFE provides the chemical- and temperature-resistant sealing face, while the energizer provides the consistent mechanical load needed for a proper seal.

Leveraging System Pressure

When installed, the energizer is compressed, applying a constant outward force on the PTFE jacket to create a tight initial barrier.

Crucially, when the system is pressurized, that pressure finds its way into the seal groove and pushes on the inside of the PTFE jacket. This system pressure adds to the spring's force, creating an even tighter and more reliable seal as pressure increases.

Compensating for Material Weakness

PTFE is a fantastic material, but it has low elasticity. On its own, it would suffer from compression set and fail to "rebound" to maintain a seal.

The internal spring energizer completely solves this problem. It provides permanent elasticity, ensuring the seal lips remain in contact with the mating surfaces despite wear, thermal cycling, or pressure changes.

Key Advantages in Oil and Gas Applications

The unique design of PTFE energized seals makes them a preferred solution for the industry's most critical challenges.

Unmatched Chemical Resistance

The carbon-fluorine bonds in PTFE make it one of the most chemically inert polymers available.

It is virtually immune to attack from the aggressive media found in oil and gas, including sour gas (H2S), acid gas, steam, hot water, and nearly all industrial acids, bases, and solvents.

Extreme Temperature and Pressure Tolerance

These seals operate reliably across an exceptionally wide service range where other materials would degrade or fail.

Typical performance includes cryogenic service down to -425°F (-254°C) and high-temperature service up to 575°F (300°C). They are also engineered for high-pressure ratings, often exceeding 30,000 psi.

Longevity and Reliability

PTFE's very low coefficient of friction results in low wear and a long service life, especially in dynamic applications.

Unlike many elastomers, the energized design is immune to aging embrittlement and compression set, ensuring consistent performance over time without leakage.

Understanding the Trade-offs

While highly effective, these seals are a specialized solution. Understanding their limitations is key to using them correctly.

Material Properties to Manage

PTFE has poor thermal conductivity, which can be a concern in high-speed applications where friction generates heat. This can be mitigated by using PTFE blends with fillers like copper or graphene to improve heat dissipation.

The Impact of Cost

PTFE energized seals are a premium product with a higher initial cost than standard elastomeric seals.

Their use is justified in critical, high-consequence applications where the cost of failure—in terms of downtime, safety, or environmental impact—far outweighs the component cost. Strategic use in the most demanding locations is the most cost-effective approach.

Making the Right Choice for Your Application

The decision to use a PTFE energized seal should be based on the specific demands of the operating environment.

- If your primary focus is reliability in chemically aggressive media: These seals are an ideal choice due to PTFE's near-universal chemical inertness, especially against sour and acid gas.

- If your primary focus is performance across extreme temperature or pressure ranges: The energized design ensures a consistent and reliable sealing force where traditional elastomers would fail.

- If your primary focus is cost-optimization for a standard application: For less demanding conditions without extreme temperatures or chemicals, a standard elastomer seal may be a more cost-effective solution.

Ultimately, selecting a PTFE energized seal is an investment in operational certainty for the most challenging conditions your equipment will face.

Summary Table:

| Feature | Benefit in Oil & Gas |

|---|---|

| PTFE Jacket | Exceptional chemical resistance to sour gas, acids, and solvents. |

| Spring Energizer | Maintains a constant, reliable seal, immune to compression set. |

| Wide Temperature Range | Performs from cryogenic (-425°F) to high heat (575°F). |

| High-Pressure Capability | Engineered for pressures exceeding 30,000 psi. |

| Low Friction | Reduces wear for long service life in dynamic applications. |

Invest in operational certainty for your most critical applications. The demanding environments of the oil and gas industry require seals you can trust. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom energized seals, for the semiconductor, medical, laboratory, and industrial sectors. We ensure reliability from prototype to high-volume production. Let's discuss how our seals can enhance the safety and efficiency of your equipment—contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments