At its core, PTFE gaskets improve sealing efficiency by physically deforming to fill the microscopic imperfections present on all sealing surfaces. Their unique softness and high compressibility allow them to flow into tiny cracks and compensate for deviations from machining, flange warping, or uneven bolt loads, creating a highly effective and reliable barrier against leaks.

The true advantage of PTFE is its rare combination of physical conformability and elite chemical and thermal resistance. It doesn't just create a seal; it maintains that seal under conditions that would cause most other materials to fail.

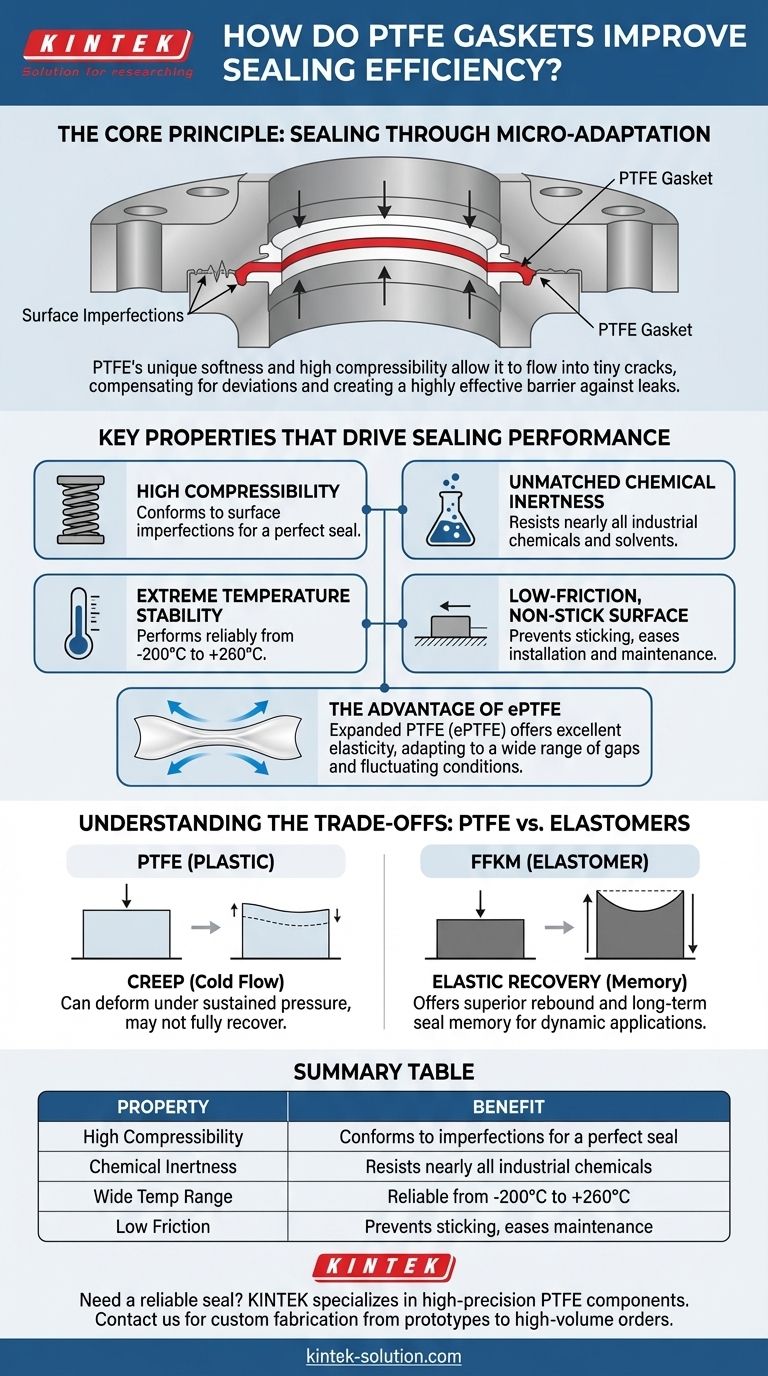

The Core Principle: Sealing Through Micro-Adaptation

The primary function of any gasket is to create a seal between two imperfect surfaces. PTFE excels at this by adapting its shape under pressure to create a perfect, leak-proof interface.

Compensating for Surface Imperfections

No flange or sealing surface is perfectly flat. PTFE's softness allows it to compensate for common deviations caused by machining, stiffness deformation, installation displacement, or uneven preload from bolts.

The material essentially molds itself to the unique topography of the surfaces it's sealing.

The Role of Softness and Compression

PTFE has a large compression ratio. When compressed, it easily forms into a three-dimensional shape that can embed into fine cracks and scratches on the flange face.

This action closes off potential leak paths that a harder, less conformable material would miss, ensuring a tighter and more durable seal.

The Advantage of Expanded PTFE (ePTFE)

Expanded PTFE (ePTFE) enhances these properties further. It possesses excellent elasticity and plasticity, allowing it to adapt to a wide range of sealing gap sizes.

This makes it particularly effective in maintaining a reliable seal under the fluctuating conditions of high temperature and high pressure.

Key Properties That Drive Sealing Performance

Beyond its ability to conform, PTFE possesses a unique set of inherent properties that make it an ideal sealing material for demanding industrial environments.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. Its inert nature prevents it from degrading, swelling, or contaminating the process media.

This makes it a default choice for industries requiring high purity, such as chemical processing, pharmaceuticals, and food production.

Extreme Temperature Stability

PTFE gaskets perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This stability ensures the seal remains intact during extreme thermal cycling, preventing leaks caused by material expansion or contraction.

Low-Friction, Non-Stick Surface

The material's low coefficient of friction and non-stick properties prevent it from sticking to flange surfaces. This not only eases installation and removal but also reduces the maintenance effort and potential damage to equipment.

Understanding the Trade-offs: PTFE vs. Elastomers

While PTFE is an exceptional material, its primary limitation lies in its nature as a plastic, not a true elastomer. This introduces specific trade-offs that are critical to understand.

The Challenge of "Creep"

Under sustained pressure and temperature, PTFE can be subject to creep, also known as cold flow. This means the material can slowly deform over time and may not return to its original shape when the load is removed.

In applications with frequent pressure cycles or thermal changes, this can eventually lead to a loss of sealing stress.

When to Consider Alternatives like FFKM

For demanding applications requiring long-term seal "memory" and elasticity, a perfluoroelastomer (FFKM) may be a superior choice.

FFKM offers similar chemical and temperature resistance to PTFE but with vastly improved elastic properties. It can rebound after compression, making it better suited for dynamic sealing or where maintaining consistent bolt torque over years of service is critical.

Making the Right Choice for Your Application

Selecting the correct gasket material requires matching its properties to the specific demands of your system.

- If your primary focus is aggressive chemical resistance or process purity: PTFE is an ideal choice due to its near-total chemical inertness.

- If your system operates at extreme hot or cold temperatures: PTFE's wide and stable operating range makes it a top-tier performer.

- If your application involves high-pressure cycling and requires long-term elastic recovery: You should evaluate a high-performance elastomer like FFKM.

Ultimately, understanding PTFE's unique ability to conform and resist harsh environments empowers you to build more reliable and efficient systems.

Summary Table:

| Property | Benefit |

|---|---|

| High Compressibility | Conforms to surface imperfections for a perfect seal |

| Chemical Inertness | Resists nearly all industrial chemicals and solvents |

| Wide Temperature Range | Performs reliably from -200°C to +260°C |

| Low Friction Surface | Prevents sticking, eases installation and maintenance |

Need a reliable seal for your demanding application?

KINTEK specializes in manufacturing high-precision PTFE components, including seals, gaskets, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment achieves leak-proof performance, even under extreme chemical and thermal conditions.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and durability.

Contact us today to discuss your specific sealing requirements and discover how our PTFE solutions can enhance your system's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications