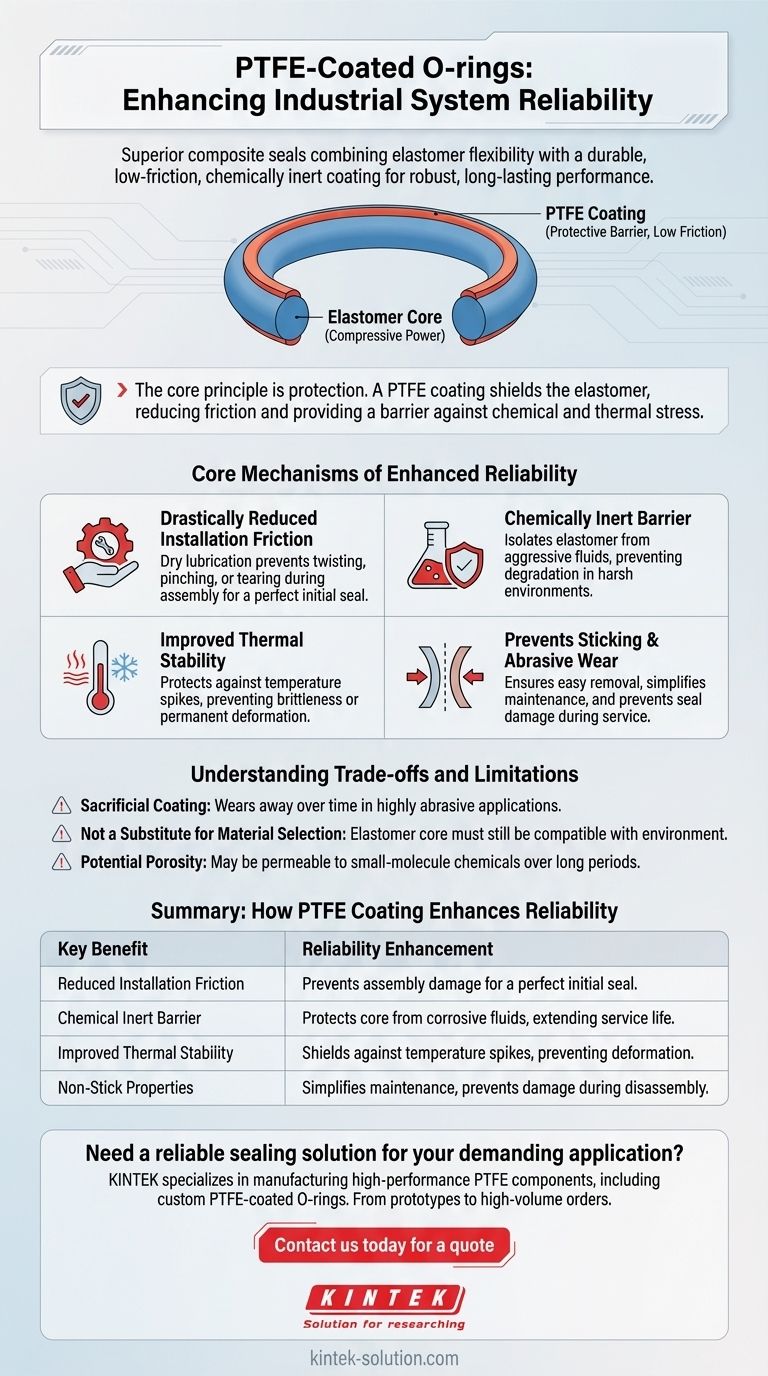

In short, PTFE-coated O-rings contribute to system reliability by creating a superior composite seal. They combine the flexible, compressive sealing power of an elastomer core with a durable, low-friction, and chemically inert surface coating. This unique pairing directly mitigates common failure points like installation damage, chemical degradation, and friction-related wear, ensuring a more robust and long-lasting seal in demanding industrial environments.

The core principle is protection. A PTFE coating doesn't replace the sealing function of the elastomer; it shields it. By reducing friction during assembly and providing a barrier against chemical and thermal stress, the coating ensures the underlying O-ring can perform its critical job without premature failure.

The Core Mechanisms of Enhanced Reliability

To understand the value of a PTFE-coated O-ring, it's essential to break down how the thin surface layer fundamentally changes its performance characteristics. The coating addresses the inherent vulnerabilities of a standard elastomer seal.

Drastically Reducing Installation Friction

One of the most common causes of O-ring failure is damage during installation. Twisting, pinching, or tearing can create a leak path before the system is ever pressurized.

A PTFE coating provides exceptional dry lubrication. This low-friction surface allows the O-ring to slide into place smoothly without bunching or tearing, drastically increasing the likelihood of a perfect initial seal.

Providing a Chemically Inert Barrier

While the base elastomer provides the compressive force, it may be vulnerable to aggressive chemicals that cause it to swell, harden, or degrade over time.

The PTFE layer acts as a protective barrier, isolating the more sensitive elastomer from direct contact with corrosive fluids. This is critical in applications like chemical processing, pharmaceutical research, and oil and gas exploration.

Improving Performance at Temperature Extremes

The PTFE coating adds a layer of thermal stability. It helps protect the underlying elastomer from brief temperature spikes that might otherwise cause it to become brittle or deform permanently.

This makes PTFE-coated seals highly valuable in automotive engines, aerospace hydraulic systems, and other environments with significant temperature fluctuations.

Preventing Sticking and Abrasive Wear

In dynamic applications or assemblies that require periodic disassembly, standard O-rings can stick to mating surfaces. This can damage the seal during removal or cause "stick-slip" behavior during operation.

The non-stick properties of PTFE ensure easy removal and clean separation. This simplifies maintenance and prevents the seal from being destroyed during service, a key factor in food, beverage, and water treatment equipment.

Understanding the Trade-offs and Limitations

While highly effective, a PTFE coating is not a universal solution. Acknowledging its limitations is key to making an informed engineering decision and ensuring genuine system reliability.

The Coating is Sacrificial

The PTFE layer is extremely thin—often just a few micrometers. It is not an indestructible shield.

In highly abrasive or dynamic applications, the coating is designed to wear away over time. Its primary benefit may be limited to ensuring a flawless installation and providing short-term protection.

Not a Substitute for Correct Material Selection

The coating enhances the properties of the O-ring, but it cannot fix a fundamentally incorrect material choice.

You must still select an elastomer core (such as FKM, EPDM, or NBR) that is broadly compatible with your application's temperature, pressure, and chemical environment. The coating is a performance multiplier, not a cure-all.

Porosity Can Be a Factor

While the coating is a strong chemical barrier, it is not completely impermeable.

Over long periods, highly aggressive or small-molecule chemicals can slowly permeate the porous coating and reach the elastomer underneath. This means for long-term exposure to extreme chemicals, a solid PTFE or perfluoroelastomer (FFKM) O-ring may be necessary.

Making the Right Choice for Your Application

Selecting the right seal requires aligning its specific benefits with your system's primary reliability goals.

- If your primary focus is preventing installation damage: PTFE-coated O-rings are an exceptional choice, as their dry lubrication is one of the most effective ways to avoid assembly-related failures.

- If your primary focus is moderate chemical resistance: The coating offers a cost-effective way to protect a standard elastomer, extending its service life significantly in less-than-extreme chemical environments.

- If your primary focus is frequent disassembly and maintenance: The non-stick properties of the coating will simplify service and reduce the likelihood of damaging the seal during component removal.

- If your primary focus is high-speed dynamic sealing: Carefully evaluate wear rates, as the sacrificial coating may have a limited lifespan compared to seals made from internally lubricated materials.

Ultimately, selecting a PTFE-coated O-ring is a strategic decision to mitigate specific, known failure risks and enhance the long-term integrity of your critical seals.

Summary Table:

| Key Benefit | How It Enhances Reliability |

|---|---|

| Reduced Installation Friction | Prevents twisting, pinching, and tearing during assembly for a perfect initial seal. |

| Chemical Inert Barrier | Protects the elastomer core from corrosive fluids, extending service life. |

| Improved Thermal Stability | Shields the elastomer from brief temperature spikes that can cause brittleness or deformation. |

| Non-Stick Properties | Prevents sticking to mating surfaces, simplifying maintenance and preventing damage during disassembly. |

Need a reliable sealing solution for your demanding application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom PTFE-coated O-rings. We serve the semiconductor, medical, laboratory, and industrial sectors, providing precision production from prototypes to high-volume orders.

Let our expertise help you mitigate common failure points and enhance the long-term integrity of your systems. Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability