In short, PTFE coated fasteners perform exceptionally well in marine and offshore environments. Their unique combination of properties directly counters the most destructive forces found in these settings, such as extreme corrosion from saltwater and the electrochemical reaction between dissimilar metals. This makes them a highly reliable choice for protecting the integrity of critical structural connections.

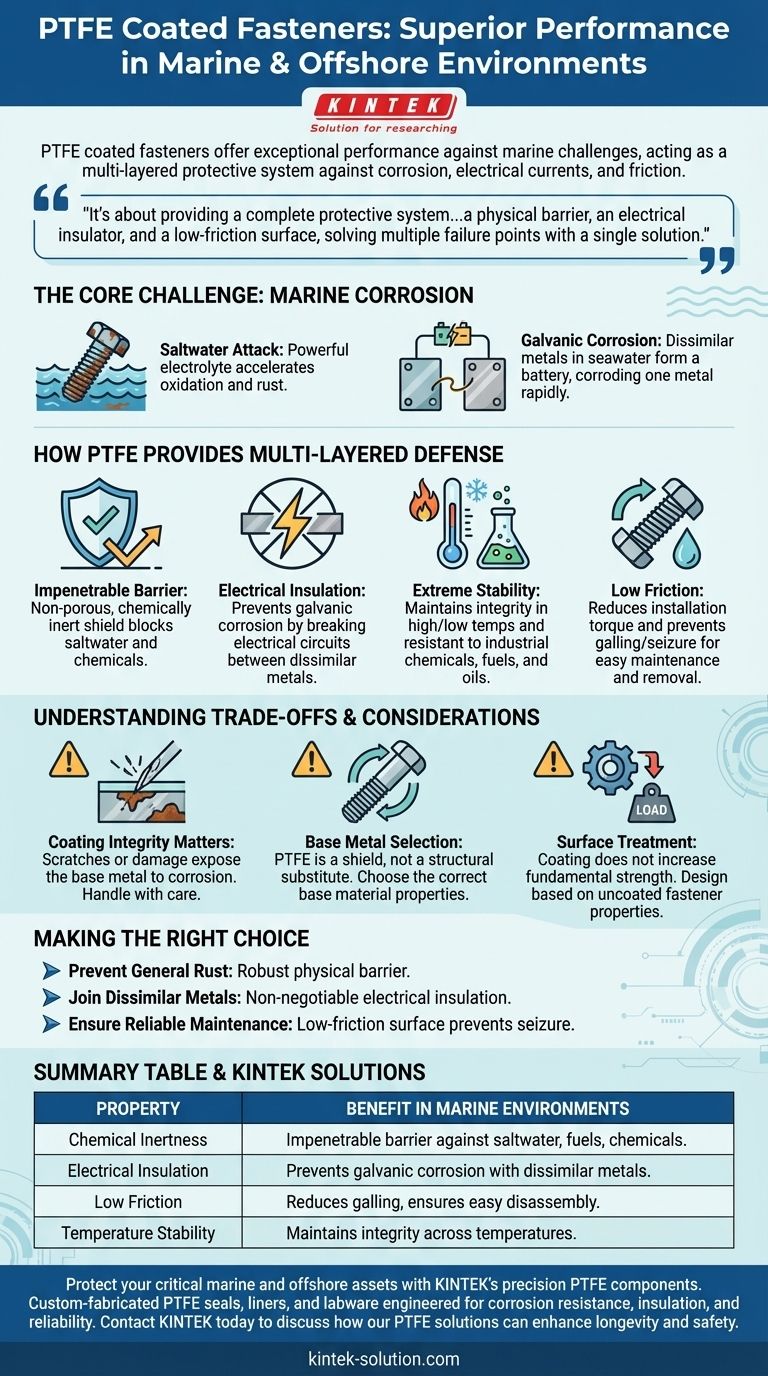

The core value of PTFE coatings in marine applications isn't just about resisting rust. It's about providing a complete protective system that acts as a physical barrier, an electrical insulator, and a low-friction surface, solving multiple failure points with a single solution.

The Core Challenge: Corrosion in Marine Environments

To understand the effectiveness of PTFE coatings, we must first appreciate the uniquely hostile nature of marine and offshore settings. Fasteners in these locations are under constant attack from multiple angles.

The Relentless Attack of Saltwater

Saltwater is a powerful electrolyte that dramatically accelerates the oxidation (rusting) of most carbon and alloy steels. Unprotected fasteners can degrade with alarming speed, compromising their strength and the safety of the entire structure.

The Hidden Danger of Galvanic Corrosion

A more insidious threat is galvanic corrosion. This occurs when two different types of metal are in electrical contact in the presence of an electrolyte like saltwater. The metals form a small battery, causing one of the metals (the less noble one) to corrode at a highly accelerated rate.

How PTFE Coatings Provide a Multi-Layered Defense

A PTFE coating isn't just a layer of paint; it's an engineered surface that offers several distinct forms of protection simultaneously, making it ideal for the complex challenges offshore.

An Impenetrable Barrier

The primary function of the PTFE coating is to create a non-porous, chemically inert shield. This barrier physically prevents saltwater, moisture, and other corrosive chemicals from ever reaching the base metal of the fastener.

Preventing Galvanic Corrosion Through Insulation

Critically, PTFE is an excellent electrical insulator. By coating the fastener, you effectively break the electrical circuit between it and the material it's bolted to. This completely neutralizes the threat of galvanic corrosion, allowing for the safe joining of dissimilar metals.

Extreme Temperature and Chemical Stability

Offshore platforms and marine vessels involve machinery and processes that create a wide range of conditions. PTFE maintains its integrity in both high and low temperatures and is resistant to virtually all industrial chemicals, fuels, and oils, ensuring the coating does not degrade over time.

Low Friction for Reliable Installation and Removal

PTFE has an extremely low coefficient of friction. This provides a major practical benefit: it reduces the torque required for proper tensioning during installation. More importantly, it prevents galling and seizure over time, ensuring that fasteners can be removed easily and predictably during maintenance, even after years of exposure.

Understanding the Trade-offs and Considerations

While highly effective, specifying PTFE coated fasteners requires a clear understanding of their limitations to ensure successful application.

The Importance of Coating Integrity

The protection is only as good as the coating. If the coating is significantly scratched or damaged during installation—for example, by a slipping wrench—the exposed base metal can become a focal point for corrosion. Proper tools and handling procedures are essential.

Base Metal Selection Still Matters

The PTFE coating is a shield, not a substitute for selecting the correct base material. The underlying fastener (e.g., B7 alloy steel, stainless steel) must still have the required mechanical properties, such as tensile strength and shear resistance, for the specific structural load it will bear.

It's a Surface Treatment, Not a Structural Enhancement

Remember that the coating adds protection and lubricity; it does not increase the fundamental strength of the fastener itself. The mechanical design must be based on the properties of the uncoated fastener.

Making the Right Choice for Your Application

Selecting PTFE coated fasteners is a strategic decision to mitigate specific risks inherent in marine and offshore construction and maintenance.

- If your primary focus is preventing general rust and extending asset life: The coating's robust physical barrier against saltwater is its most fundamental benefit.

- If your primary focus is joining dissimilar metals (e.g., a steel pipe flange to an aluminum superstructure): The electrical insulating property of PTFE is non-negotiable for preventing rapid galvanic corrosion.

- If your primary focus is ensuring reliable maintenance and future disassembly: The low-friction surface prevents fastener seizure, saving immense time, cost, and effort during planned shutdowns or repairs.

Ultimately, choosing PTFE coated fasteners is an investment in long-term reliability and operational safety for your most critical assets.

Summary Table:

| Property | Benefit in Marine Environments |

|---|---|

| Chemical Inertness | Creates an impenetrable barrier against saltwater, fuels, and chemicals. |

| Electrical Insulation | Prevents galvanic corrosion when joining dissimilar metals. |

| Low Friction | Reduces galling and seizure, ensuring easy disassembly for maintenance. |

| Temperature Stability | Maintains integrity across a wide range of operating temperatures. |

Protect your critical marine and offshore assets with KINTEK's precision PTFE components.

Our custom-fabricated PTFE seals, liners, and labware are engineered to deliver the same exceptional corrosion resistance, electrical insulation, and reliability detailed in this article. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we prioritize precision production from prototypes to high-volume orders.

Contact KINTEK today to discuss how our PTFE solutions can enhance the longevity and safety of your projects.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers