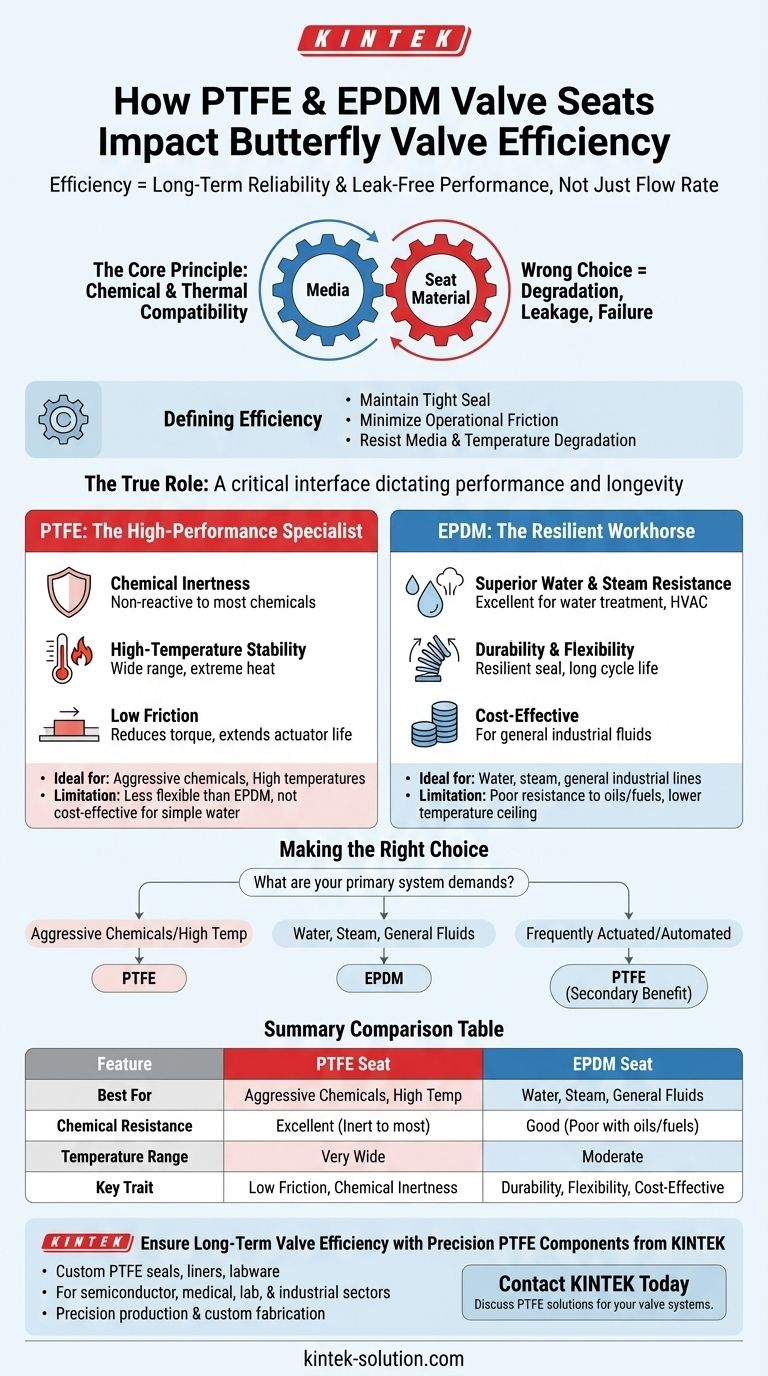

In short, PTFE and EPDM valve seats impact the efficiency of a butterfly valve by determining its suitability for a specific operating environment. The "efficiency" is not about flow rate but about long-term reliability and leak-free performance. PTFE excels in high-temperature, chemically aggressive applications due to its inertness, while EPDM provides a durable, resilient seal for water and steam systems.

The core principle is one of chemical and thermal compatibility. Choosing the wrong seat material leads to degradation, leakage, and premature failure—the ultimate form of inefficiency. The right material ensures the valve functions reliably for its intended lifespan.

The True Role of the Valve Seat

A valve seat isn't merely a passive component; it is the critical interface that dictates the valve's performance and longevity. Understanding its function is key to making the correct material choice.

Defining "Efficiency" in a Valve System

In this context, efficiency is a measure of a valve's ability to perform its function reliably over time. This includes maintaining a tight seal, minimizing operational friction, and resisting degradation from the process media and temperature.

A leaking or failing valve creates downtime and safety hazards, making it profoundly inefficient regardless of its initial flow characteristics.

The Critical Factor: Media Compatibility

The single most important factor is the interaction between the seat material and the fluid or gas passing through the valve. A material that is chemically resistant to the media will not swell, harden, or break down, ensuring a consistent and reliable seal.

A Profile of PTFE: The High-Performance Specialist

PTFE (Polytetrafluoroethylene) is a fluoropolymer engineered for the most demanding conditions. Its properties make it the default choice for harsh applications.

Unmatched Chemical Inertness

PTFE is non-reactive to nearly all industrial chemicals and corrosive substances. This inertness prevents the material from degrading, ensuring the integrity of the seal in aggressive process lines.

High-Temperature Stability

This material maintains its structural integrity and sealing capability across an exceptionally wide temperature range. This makes it essential for applications involving extreme heat where other elastomers would fail.

The Advantage of Low Friction

PTFE has an extremely low coefficient of friction. This reduces the torque required to open and close the valve, which in turn minimizes wear on the valve stem and actuator components, extending the life of automated valve systems.

A Profile of EPDM: The Resilient Workhorse

EPDM (Ethylene Propylene Diene Monomer) is a versatile synthetic rubber known for its durability and flexibility in less chemically aggressive, but still demanding, environments.

Superior Water and Steam Resistance

EPDM's primary strength is its excellent resistance to water, steam, and polar solvents. This makes it the ideal and cost-effective choice for water treatment, HVAC systems, and general industrial water lines.

Durability and Flexibility

EPDM is highly resilient and flexible, allowing it to maintain a tight seal even after thousands of cycles. This physical toughness ensures reliable performance and a long service life in its recommended applications.

Understanding the Trade-offs and Pitfalls

No single material is universally superior. The most common cause of valve failure is a mismatch between the seat material and the operational demands.

The Limitations of PTFE

While superior in chemical and heat resistance, PTFE can be less flexible than EPDM. It may not be the ideal choice for simple, low-pressure water applications where the high-performance properties are unnecessary and not cost-effective.

The Boundaries of EPDM

EPDM's primary limitation is its poor resistance to hydrocarbon-based oils, fuels, and non-polar solvents. Using an EPDM seat in these environments will cause it to swell and degrade rapidly, leading to guaranteed valve failure. Its temperature ceiling is also significantly lower than that of PTFE.

Making the Right Choice for Your Application

Your selection should be based on a clear analysis of your system's media, temperature, and pressure.

- If your primary focus is handling aggressive chemicals or high temperatures: PTFE is the correct choice, as its chemical inertness and thermal stability are essential for system integrity.

- If your primary focus is managing water, steam, or general industrial fluids: EPDM provides a durable, reliable, and cost-effective seal perfectly suited for these common applications.

- If your primary focus is frequently actuated or automated systems: PTFE's low friction can reduce actuator strain, but this benefit is secondary to ensuring fundamental chemical compatibility first.

Ultimately, selecting the correct valve seat is the most critical decision in guaranteeing the long-term efficiency and reliability of your butterfly valve.

Summary Table:

| Feature | PTFE Seat | EPDM Seat |

|---|---|---|

| Best For | Aggressive Chemicals, High Temperatures | Water, Steam, General Industrial Fluids |

| Chemical Resistance | Excellent (Inert to most chemicals) | Good (Poor with oils/fuels) |

| Temperature Range | Very Wide | Moderate |

| Key Trait | Low Friction, Chemical Inertness | Durability, Flexibility, Cost-Effectiveness |

Ensure Long-Term Valve Efficiency with Precision PTFE Components

Selecting the correct valve seat material is critical for preventing downtime and ensuring safety. KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific media, temperature, and pressure requirements.

Contact us today to discuss how our PTFE solutions can enhance the reliability and efficiency of your valve systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions