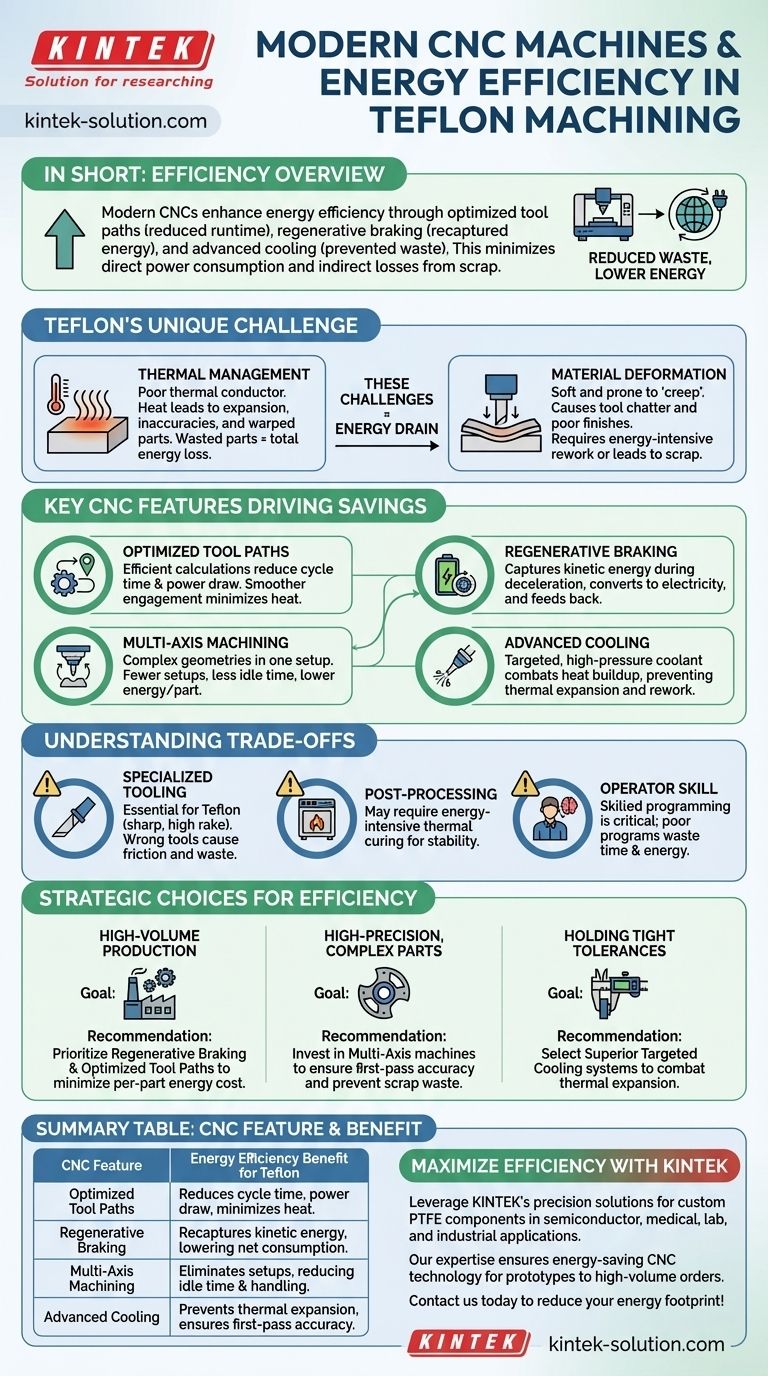

In short, modern CNC machines enhance energy efficiency in Teflon machining through a combination of optimized tool paths that reduce runtime, regenerative braking systems that recapture energy, and advanced cooling methods that prevent material waste. These features work together to minimize both direct power consumption and the indirect energy losses associated with scrap and rework.

The core principle of energy efficiency in Teflon machining extends beyond simple power usage. True efficiency is achieved by using advanced machine capabilities to precisely counteract Teflon's challenging properties—its softness, thermal expansion, and tendency to deform—thereby minimizing wasted material, energy, and time.

Redefining Efficiency: The Teflon Challenge

Machining Teflon (PTFE) presents a unique set of challenges that directly impact energy consumption. Unlike metals, where efficiency often relates to raw power and cutting speed, efficiency with Teflon is about control and finesse.

The Problem of Thermal Management

Teflon is a poor thermal conductor. Heat generated during cutting does not dissipate quickly, causing the material to expand significantly.

This localized heating can lead to dimensional inaccuracies, part warping, and ultimately, scrapped parts. Wasted parts represent a total loss of the energy invested in producing them.

The Difficulty of Material Deformation

Teflon is soft and prone to "creep," meaning it deforms under sustained pressure from a cutting tool. This can cause tool chatter, poor surface finishes, and difficulty holding tight tolerances.

Correcting these issues requires additional machine time, secondary operations, or scrapping the part entirely—all of which are highly energy-intensive.

Key CNC Features Driving Energy Savings

Modern CNC machines incorporate specific technologies designed to overcome Teflon's challenges, leading to direct and indirect energy savings.

Optimized Tool Paths

Advanced CAM software integrated with modern CNC controllers calculates the most efficient path for the cutting tool. This eliminates wasted motion, reduces overall cycle time, and minimizes the duration of machine power draw.

For Teflon, this also means smoother, more consistent tool engagement, which reduces heat generation and the risk of material smearing.

Regenerative Braking Systems

When a CNC machine’s spindle or axes decelerate, their kinetic energy is typically lost as heat.

Regenerative braking systems capture this energy, convert it into electricity, and feed it back into the machine's power system. This directly reduces the net energy consumed during cycles with frequent acceleration and deceleration.

Multi-Axis Machining

Using a 5-axis or other multi-axis CNC machine allows for the machining of complex geometries in a single setup.

This dramatically reduces total production time by eliminating the need for multiple machine setups and part handling. Less machine idle time and fewer operations translate directly to lower overall energy consumption per part.

Advanced Cooling Systems

Modern machines offer sophisticated cooling options like high-pressure, through-spindle coolant. This delivers a precise, powerful stream of coolant directly to the cutting edge.

This is far more effective at managing Teflon's heat buildup than traditional flood cooling, preventing thermal expansion and ensuring parts are machined to specification on the first attempt. This precision is key to avoiding the energy waste of rework.

Understanding the Trade-offs and Pitfalls

While advanced technology provides significant advantages, it is not a complete solution on its own. Achieving true efficiency requires a holistic approach.

The Need for Specialized Tooling

Even the most advanced CNC machine will perform inefficiently if paired with the wrong cutting tools.

For Teflon, extremely sharp tools with high rake and clearance angles, sometimes with specialized diamond coatings, are essential. Using incorrect tooling causes friction, heat, and material deformation, negating the machine's efficiency features.

The Reality of Post-Processing

Despite the precision of modern CNCs, the inherent properties of Teflon can sometimes necessitate post-processing steps like thermal curing to relieve internal stresses and stabilize dimensions.

This is an additional, energy-consuming step that must be factored into the total manufacturing process.

The Operator Skill Requirement

An advanced CNC machine is only as efficient as the program it runs. A skilled programmer who understands Teflon's unique behavior is critical.

A poorly optimized program can easily waste time and energy, overriding the machine's inherent capabilities.

Making the Right Choice for Your Goal

To maximize energy efficiency, align your technology choices with the primary requirements of your project.

- If your primary focus is high-volume production: Prioritize machines with regenerative braking and sophisticated tool path optimization software to minimize the per-part energy cost.

- If your primary focus is high-precision, complex parts: Invest in multi-axis machines to reduce setups and ensure first-pass accuracy, which prevents the significant energy waste of scrapped components.

- If your primary focus is holding tight tolerances: Select machines with superior, targeted cooling systems to directly combat Teflon's thermal expansion and ensure dimensional stability.

Ultimately, leveraging modern CNC technology transforms Teflon from a difficult material into a predictable medium, ensuring that energy is invested in creating quality parts, not wasted on fighting the material itself.

Summary Table:

| CNC Feature | Energy Efficiency Benefit for Teflon |

|---|---|

| Optimized Tool Paths | Reduces cycle time and power draw, minimizes heat generation. |

| Regenerative Braking | Recaptures kinetic energy during deceleration, lowering net power consumption. |

| Multi-Axis Machining | Eliminates multiple setups, reducing idle time and part handling energy. |

| Advanced Cooling Systems | Prevents thermal expansion and scrap, ensuring first-pass accuracy. |

Maximize your Teflon machining efficiency with KINTEK's precision solutions.

Our expertise in custom PTFE components for semiconductor, medical, laboratory, and industrial applications ensures your projects benefit from energy-saving CNC technology. From prototypes to high-volume orders, we deliver precision and sustainability.

Contact us today to discuss your specific needs and reduce your energy footprint!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability