The fundamental difference lies in its structure. Expanded PTFE (ePTFE) gaskets are manufactured through a special process that transforms solid PTFE into a porous, multi-directional fibrous material, giving them a unique combination of flexibility and strength that is superior to solid or filled PTFE gaskets in many demanding applications.

The core takeaway is that ePTFE is not just another type of PTFE; it's a re-engineered material. Its unique fibrous microstructure directly solves the primary weaknesses of standard PTFE—creep and cold flow—while dramatically enhancing its ability to conform to imperfect surfaces, creating a more reliable and durable seal.

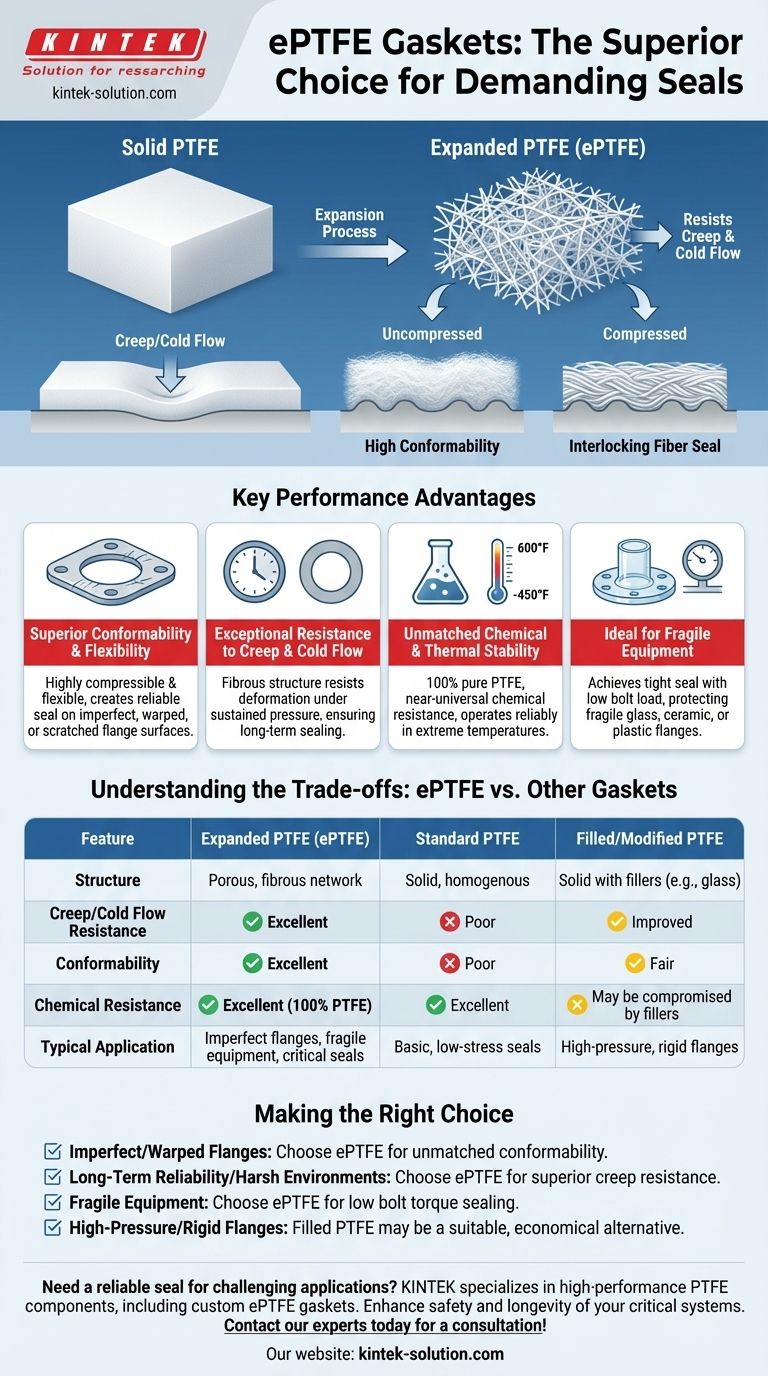

The Core Difference: From Solid to Fibrous Structure

The advantages of ePTFE all stem from its unique physical form. Unlike standard PTFE, which is a solid, homogenous material, ePTFE has a microporous structure composed of interconnected fibers.

How Expansion Creates a Superior Seal

The expansion process creates a material with a fine, bi-directional fiber structure. When uncompressed, this structure is highly elastic and soft, allowing it to easily conform to surface irregularities on a flange.

The Interlocking Fiber Advantage

Upon compression from bolt load, these fibers interlock and densify. This creates an incredibly strong, solid, and impermeable structure that maintains the seal without crushing the gasket material itself.

Key Performance Advantages of ePTFE

This unique structure translates directly into measurable performance benefits that solve common sealing challenges where other gaskets fail.

Superior Conformability and Flexibility

Expanded PTFE is highly compressible and flexible. This allows it to create a reliable seal even on scratched, warped, or otherwise imperfect flange surfaces that would be impossible to seal with a more rigid gasket material.

Exceptional Resistance to Creep and Cold Flow

Creep, or cold flow, is the tendency of a material to deform under sustained pressure, a known weakness of standard PTFE. The fibrous structure of ePTFE resists this deformation, ensuring the gasket maintains its sealing pressure over long periods and through thermal cycles.

Unmatched Chemical and Thermal Stability

Because it is made from 100% pure PTFE, ePTFE retains its parent material's outstanding properties. It has near-universal chemical resistance and operates reliably in extreme temperatures, from -450°F to 600°F (-268°C to 315°C).

Ideal for Fragile Equipment

The high compressibility of ePTFE allows it to achieve a tight seal with a much lower bolt load. This is critical for protecting fragile equipment flanges, such as those made of glass, ceramic, or plastic, from cracking or damage.

Understanding the Trade-offs: ePTFE vs. Other Gaskets

While highly versatile, ePTFE is part of a family of materials, and choosing the right one depends on the specific application.

ePTFE vs. Standard (Virgin) PTFE

Standard PTFE is a reliable, chemically inert material, but it is prone to cold flow. ePTFE solves the cold flow problem and offers vastly superior conformability, making it the better choice for virtually all demanding sealing applications.

ePTFE vs. Modified (Filled) PTFE

Modified PTFE gaskets incorporate fillers like glass fiber or silica to improve strength and reduce creep. While these fillers enhance durability, they can reduce the gasket's flexibility and chemical resistance. ePTFE often provides a more reliable seal on irregular surfaces without compromising on chemical compatibility.

Making the Right Choice for Your Application

Selecting the correct gasket is critical for improving the safety, reliability, and service life of your equipment.

- If your primary focus is sealing irregular, warped, or damaged flanges: Choose ePTFE for its unmatched conformability and ability to fill in surface imperfections.

- If your primary focus is long-term reliability in harsh chemical or high-temperature environments: Choose ePTFE for its superior resistance to creep and cold flow, which prevents leaks over time.

- If your primary focus is protecting fragile, non-metallic, or glass-lined flanges: Choose ePTFE to achieve a reliable seal with the low bolt torque required to prevent equipment damage.

- If your primary focus is a high-pressure application with perfect, rigid flanges: A filled or modified PTFE gasket may offer a suitable, often more economical, alternative.

Ultimately, choosing the right material ensures the integrity and longevity of your critical systems.

Summary Table:

| Feature | Expanded PTFE (ePTFE) | Standard PTFE | Filled/Modified PTFE |

|---|---|---|---|

| Structure | Porous, fibrous network | Solid, homogenous | Solid with fillers (e.g., glass) |

| Creep/Cold Flow Resistance | Excellent | Poor | Improved |

| Conformability to Irregular Surfaces | Excellent | Poor | Fair |

| Chemical Resistance | Excellent (100% PTFE) | Excellent | May be compromised by fillers |

| Typical Application | Imperfect flanges, fragile equipment, critical seals | Basic, low-stress seals | High-pressure, rigid flanges |

Need a reliable seal for challenging applications?

KINTEK specializes in manufacturing high-performance PTFE components, including precision ePTFE gaskets. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution that delivers superior conformability, resists cold flow, and protects your equipment.

Let us help you enhance the safety and longevity of your critical systems. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech