To select the right PTFE filler, you must match the unique properties imparted by the filler to the specific demands of your application. The choice is a direct function of the performance you need, such as enhanced wear resistance, compressive strength, or thermal conductivity. Virgin PTFE is an excellent starting point, but its performance is fundamentally altered—for better and for worse—by the inclusion of a filler material.

The core challenge is not simply picking a filler, but understanding that every filler introduces a trade-off. You are enhancing one property, like wear resistance, often at the expense of another, like chemical inertness or mating surface kindness.

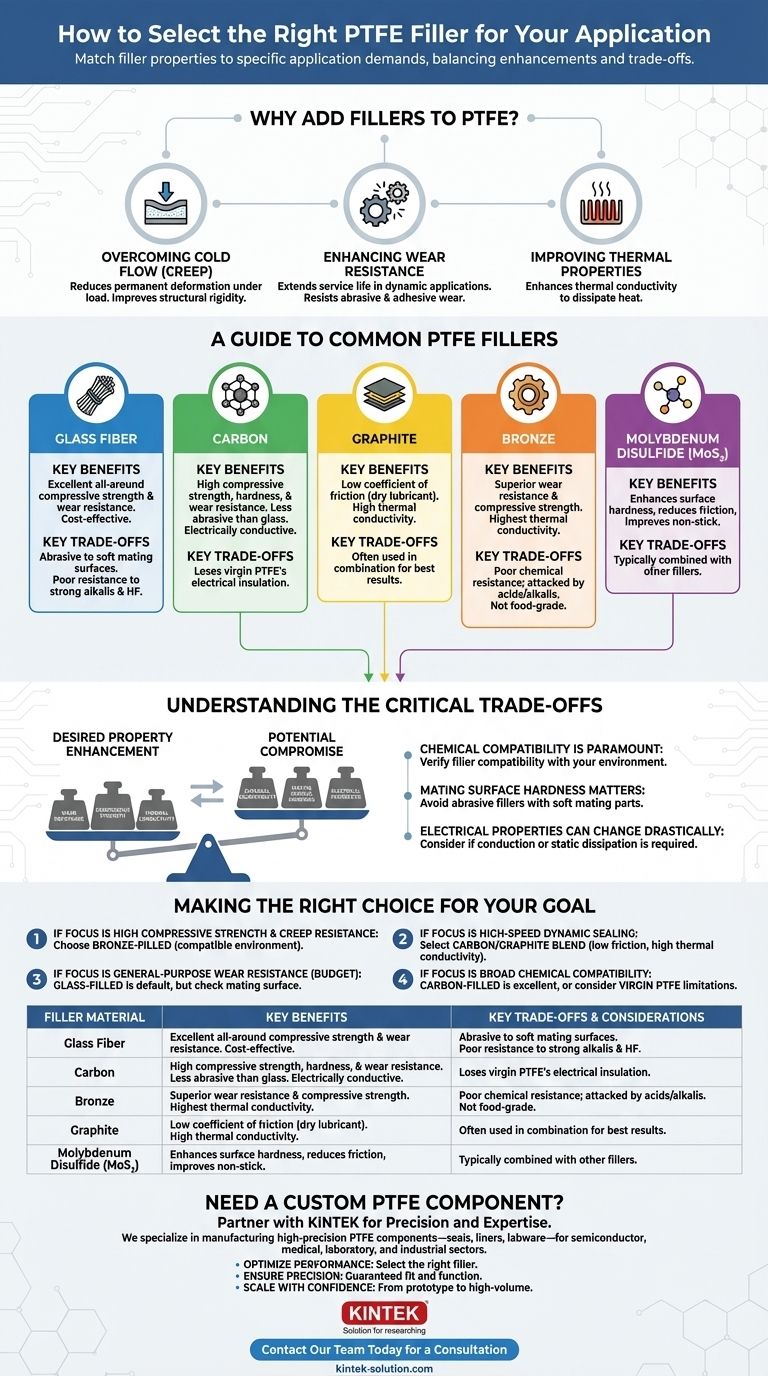

Why Add Fillers to PTFE?

Virgin Polytetrafluoroethylene (PTFE) is a remarkable material known for its extremely low coefficient of friction and broad chemical resistance. However, it has significant limitations that fillers are designed to overcome.

Overcoming Cold Flow (Creep)

Virgin PTFE is mechanically soft and susceptible to creep, or "cold flow," where the material deforms permanently under sustained load, even at room temperature. Fillers add a rigid structural matrix within the PTFE, drastically improving its resistance to deformation.

Enhancing Wear Resistance

PTFE's softness also means it wears quickly in dynamic applications. Hard filler particles distributed throughout the material significantly increase its resistance to abrasive and adhesive wear, extending the service life of components like seals and bearings.

Improving Thermal Properties

PTFE is a poor thermal conductor, which can lead to heat buildup at the wear surface in high-speed applications. Fillers like bronze or carbon dramatically improve thermal conductivity, allowing heat to dissipate away from the contact surface.

A Guide to Common PTFE Fillers

Each filler material imparts a distinct set of characteristics. Understanding these profiles is the key to making an informed choice.

Glass Fiber

Glass is the most common filler. It offers an excellent all-around improvement in compressive strength and wear resistance. It is also relatively cost-effective.

However, glass fiber is abrasive to mating surfaces, especially softer metals like aluminum or stainless steel if they are not sufficiently hardened. It also has poor resistance to strong alkalis and hydrofluoric acid (HF).

Carbon

Carbon, often in fiber or powder form, significantly increases compressive strength, hardness, and wear resistance. It has excellent chemical resistance and is much less abrasive than glass, making it suitable for use against softer metals.

Carbon-filled grades are also electrically conductive, which can be an advantage for dissipating static electricity or a disadvantage in applications requiring electrical insulation.

Graphite

Graphite is primarily added to reduce the coefficient of friction, especially in high-speed applications. It is an excellent dry lubricant and has high thermal conductivity.

It is often used in combination with other fillers, such as carbon, to create a compound with low friction, good wear resistance, and high thermal stability.

Bronze

Bronze powder provides the best improvement in wear resistance and compressive strength. It also has the highest thermal conductivity of the common fillers, making it ideal for high-load, high-speed applications where heat dissipation is critical.

The major drawback of bronze is its poor chemical resistance. It is easily attacked by acids and alkalis and will oxidize, making it unsuitable for many corrosive environments or food-grade applications.

Molybdenum Disulfide (MoS₂)

Often called "moly," MoS₂ is another dry lubricant that enhances surface hardness and reduces friction. It creates a slicker surface than graphite but provides less of a benefit to wear resistance on its own.

For this reason, moly is almost always used in combination with other fillers like glass or bronze to further reduce friction and improve non-stick properties.

Understanding the Critical Trade-offs

Selecting a filler is an exercise in balancing competing requirements. Ignoring these trade-offs is a common source of failure.

Chemical Compatibility is Paramount

The exceptional chemical inertness of virgin PTFE can be compromised by the filler. As noted, bronze has poor chemical resistance, and glass is attacked by certain chemicals. Always verify that the filler material is compatible with your service environment.

Mating Surface Hardness Matters

An abrasive filler like glass can quickly destroy a softer mating surface. For dynamic seals or bearings running against unhardened steel, aluminum, or plastic, a less abrasive filler like carbon/graphite is a much safer choice.

Electrical Properties Can Change Drastically

Virgin PTFE is an excellent electrical insulator. The addition of carbon or bronze fillers can make the material electrically conductive or static dissipative. This can be a critical design consideration, either as a desired feature or a potential failure point.

Making the Right Choice for Your Goal

To finalize your selection, analyze your application's primary demand and choose the filler that best serves that need.

- If your primary focus is high compressive strength and creep resistance: Choose a bronze-filled compound, provided the chemical environment is compatible.

- If your primary focus is high-speed dynamic sealing: Select a carbon/graphite blend for its low friction and excellent thermal conductivity.

- If your primary focus is general-purpose wear resistance on a budget: A glass-filled compound is often the default choice, but ensure your mating surface is sufficiently hard.

- If your primary focus is broad chemical compatibility: A carbon-filled compound is an excellent choice, but for ultimate inertness, you may need to design around the limitations of virgin PTFE.

Ultimately, the right choice comes from a clear understanding of your specific operating conditions and performance goals.

Summary Table:

| Filler Material | Key Benefits | Key Trade-offs & Considerations |

|---|---|---|

| Glass Fiber | Excellent all-around wear resistance & compressive strength; cost-effective. | Abrasive to softer mating surfaces; poor resistance to strong alkalis & HF. |

| Carbon | High compressive strength & wear resistance; less abrasive; electrically conductive. | Loses virgin PTFE's electrical insulation properties. |

| Bronze | Superior wear resistance & compressive strength; highest thermal conductivity. | Poor chemical resistance; attacked by acids/alkalis; not food-grade. |

| Graphite | Low coefficient of friction; excellent dry lubricant; high thermal stability. | Often used in combination with other fillers for best results. |

| Molybdenum Disulfide (MoS₂) | Enhances surface hardness; reduces friction; improves non-stick. | Typically combined with other fillers (e.g., glass, bronze). |

Need a Custom PTFE Component with the Perfect Filler?

Selecting the ideal PTFE filler is critical for your component's performance, longevity, and reliability. The experts at KINTEK are here to help you navigate these complex trade-offs.

We specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

Partner with KINTEK to:

- Optimize Performance: We'll help you select the right filler material to meet your specific requirements for wear resistance, strength, thermal conductivity, and chemical compatibility.

- Ensure Precision: Our focus on precision production guarantees components that fit and function perfectly.

- Scale with Confidence: From custom prototypes to high-volume production runs, we deliver consistent, high-quality parts.

Don't leave your component's performance to chance. Contact our team today for a consultation and let us fabricate the perfect PTFE solution for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance