The primary method for improving the mechanical properties of PTFE O-rings is to introduce reinforcing fillers into the material matrix. While virgin, or unfilled, PTFE offers exceptional chemical and thermal resistance, its mechanical strength is relatively low. Adding fillers like glass fiber, carbon, graphite, or bronze significantly enhances its strength, stability under load, and resistance to wear.

The core challenge with PTFE is balancing its unmatched chemical inertness against its inherent mechanical weaknesses, particularly its softness and tendency to creep. While fillers are the solution, they introduce trade-offs that you must understand to select the right material for your application.

Understanding PTFE's Inherent Mechanical Profile

To appreciate the impact of fillers, we must first understand the baseline properties of virgin PTFE. It is a material of remarkable contrasts.

The Chemical and Thermal Advantages

PTFE is renowned for its near-universal chemical resistance. It is impervious to almost all acids, bases, and solvents, making it a default choice for aggressive chemical environments.

It also maintains its properties across an exceptionally wide temperature range, remaining useful from cryogenic temperatures (-73°C) up to 204°C.

The Primary Weakness: Softness and Creep

Mechanically, PTFE is a soft material with low stiffness and hardness. Its most significant drawback for sealing applications is its propensity to creep, or deform permanently, when subjected to constant stress (like compression in a gland).

This means that over time, a standard PTFE O-ring can lose its sealing force, leading to potential leaks, especially in static applications.

Exceptional Friction Properties

A key advantage of PTFE is its extremely low coefficient of friction. Notably, its static and dynamic friction coefficients are nearly identical.

This unique property prevents "stick-slip" behavior, ensuring smooth, predictable motion from a standstill, which is critical in dynamic sealing applications.

Low Wear Resistance

Despite its low friction, virgin PTFE has relatively low resistance to abrasive wear. The material can be worn away quickly in dynamic applications involving rough surfaces or particulate contamination.

How Fillers Enhance Mechanical Performance

Fillers are not just additives; they are a structural reinforcement that fundamentally changes the material's behavior.

The Role of Reinforcing Additives

Fillers are non-PTFE particles dispersed throughout the PTFE matrix during its manufacturing (compression and sintering). These particles act as a rigid internal framework.

This framework helps the material resist deformation, significantly improving properties like compressive strength, wear resistance, and—most importantly—resistance to creep.

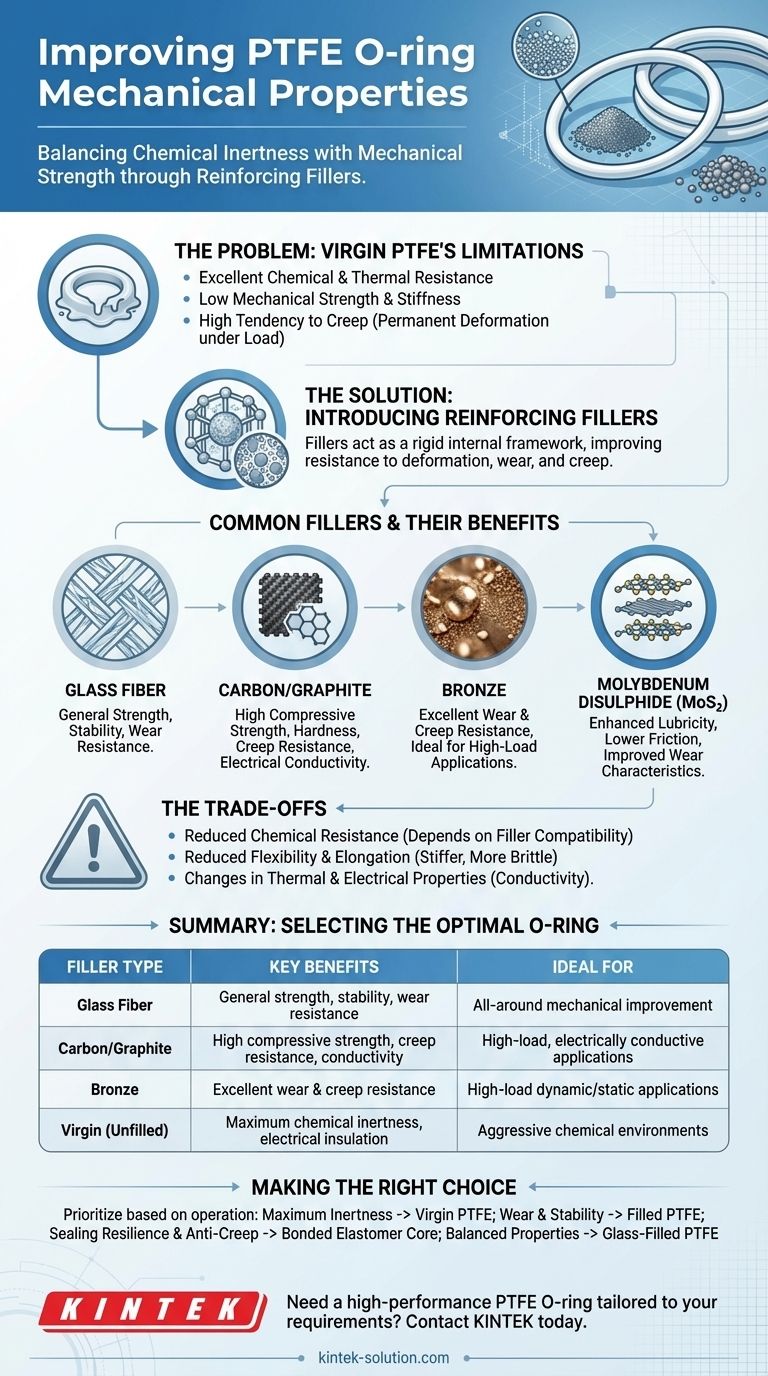

Common Fillers and Their Benefits

Different fillers are chosen to enhance specific properties:

- Glass Fibers: A common, all-around choice that improves general mechanical strength, stability, and wear resistance.

- Carbon: Significantly increases compressive strength, hardness, and creep resistance. It also adds electrical conductivity.

- Graphite: Often used with carbon, graphite improves wear properties and reduces the coefficient of friction even further.

- Bronze: Provides excellent wear resistance and the highest creep resistance, making it ideal for high-load dynamic or static applications.

- Molybdenum Disulphide (MoS₂): Added to enhance lubricity and lower friction, further improving wear characteristics.

Beyond Fillers: Structural Reinforcement

An alternative strategy to combat creep involves the O-ring's structure. Some designs incorporate a bonded rubber core inside the PTFE jacket.

The elastomer core provides constant recovery force, pushing the PTFE jacket against the sealing surfaces and compensating for any creep that might occur. This enhances the seal's long-term resilience.

Understanding the Trade-offs of Filled PTFE

Introducing fillers is not a free lunch. These enhancements to mechanical properties come with critical trade-offs that can impact your application.

Reduced Chemical Resistance

The primary trade-off is a reduction in chemical inertness. The filler material itself is not as resistant as PTFE.

For example, bronze-filled PTFE is not suitable for use with strong acids or bases that would corrode the bronze particles. You must verify the chemical compatibility of the filler, not just the PTFE.

Impact on Flexibility and Elongation

Virgin PTFE is a flexible material with very high elongation at break (up to 400%). Adding rigid fillers makes the composite material stiffer and more brittle, reducing its elongation.

This can make installation more difficult and reduces the material's ability to conform to surface imperfections.

Changes in Thermal and Electrical Properties

Virgin PTFE is an excellent thermal and electrical insulator. Fillers change this.

Carbon and bronze fillers, for instance, will make the material electrically conductive. This could be a deal-breaker in applications requiring electrical isolation.

Making the Right Choice for Your Application

The best material depends entirely on your operational priorities. Weigh the benefits of fillers against their trade-offs to select the optimal O-ring.

- If your primary focus is maximum chemical inertness and electrical insulation: Virgin (unfilled) PTFE is the only choice, but you must design your application to accommodate its low strength and tendency to creep.

- If your primary focus is wear resistance and dimensional stability under load: A filled PTFE is essential. Bronze-filled PTFE offers the best performance, provided it is chemically compatible with your media.

- If your primary focus is sealing resilience and preventing creep in a static seal: A PTFE O-ring with a bonded elastomer core is an excellent solution that combines chemical resistance with long-term sealing force.

- If your primary focus is a balance of properties for general use: Glass-filled PTFE is a common and effective starting point, offering improved mechanicals without the extreme chemical limitations of metallic fillers.

By understanding these trade-offs, you can select a PTFE variant that delivers the right balance of properties for your specific engineering challenge.

Summary Table:

| Filler Type | Key Benefits | Ideal For |

|---|---|---|

| Glass Fiber | General strength, stability, wear resistance | All-around mechanical improvement |

| Carbon/Graphite | High compressive strength, creep resistance, conductivity | High-load, electrically conductive applications |

| Bronze | Excellent wear & creep resistance | High-load dynamic/static applications |

| Virgin (Unfilled) | Maximum chemical inertness, electrical insulation | Aggressive chemical environments |

Need a high-performance PTFE O-ring tailored to your specific mechanical and chemical requirements?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom O-rings for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between chemical resistance and mechanical strength. Our experts can help you select the right filler material—from glass and carbon to bronze—or design a composite solution with a bonded elastomer core to combat creep and ensure long-term sealing force.

We offer custom fabrication from prototypes to high-volume orders, ensuring your components meet exact specifications for performance and durability.

Contact KINTEK today to discuss your application and get a solution that delivers superior reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key benefits of PTFE coatings in corrosion resistance? Achieve Unmatched Protection for Your Components

- What are the core material options for PTFE encapsulated O-rings? Choose Viton® or Silicone for Your Sealing Needs

- What role do Teflon rods play in the electrical and electronics industry? Ensure Superior Insulation and Reliability

- What factors influence the properties of compression molded PTFE parts? Master the 4 Key Processing Parameters

- What are the characteristics of a high-speed, low-pressure PTFE seal profile? Maximize Performance at 5,000 SFPM

- What types of applications are PTFE piston seals suitable for? The Ultimate Guide for Demanding Environments

- Why is material support important when machining Teflon and how is it achieved? Master Precision Machining for PTFE

- What are the advantages of using PTFE-lined valves for corrosive fluids? Achieve Superior Chemical Resistance and Reliability