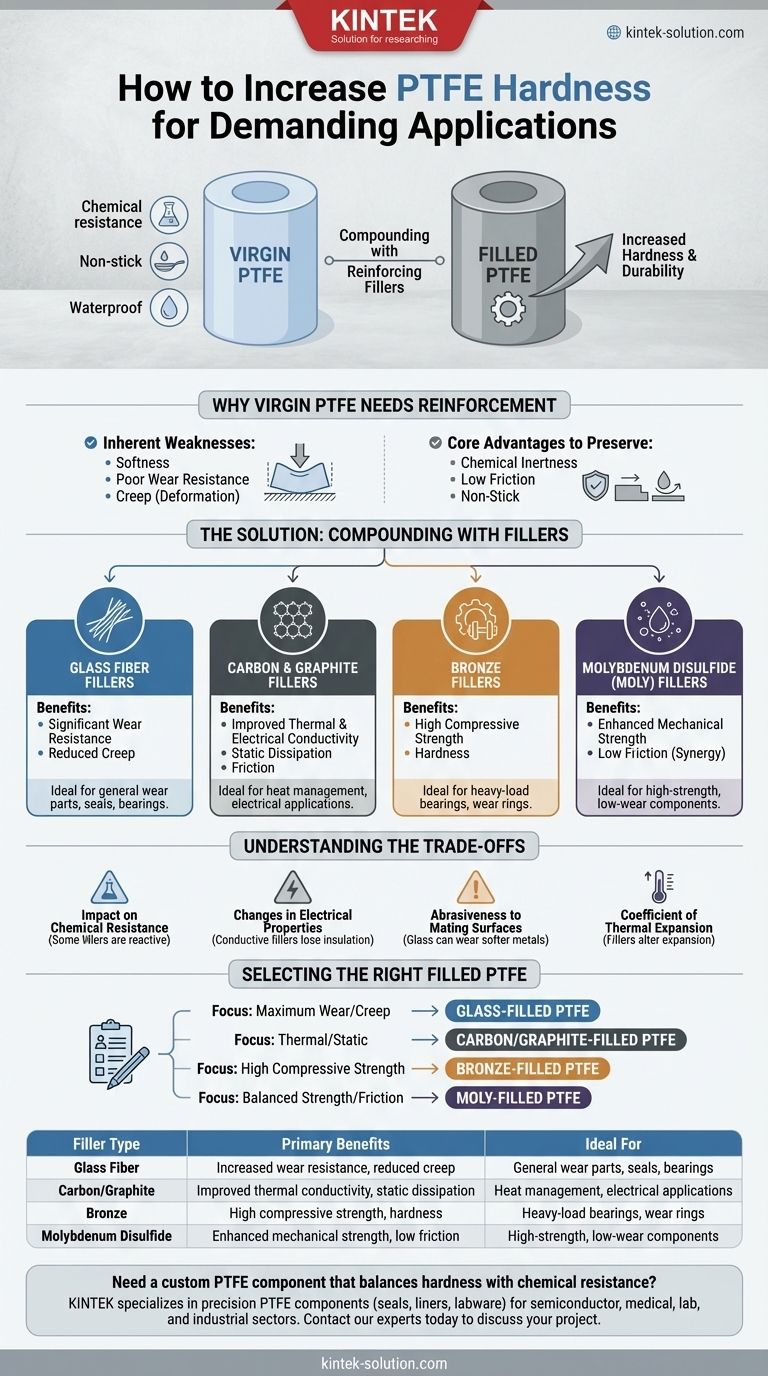

To increase the hardness and durability of PTFE, the most effective method is to compound it with reinforcing fillers. By creating filled PTFE grades, you can produce a material with significantly improved mechanical properties, including hardness, wear resistance, and reduced creep, making it suitable for high-stress environments.

The core challenge with Polytetrafluoroethylene (PTFE) is balancing its exceptional chemical inertness and low friction with its inherent softness and poor wear resistance. The solution lies in creating composite materials by adding specific fillers—such as glass, carbon, or bronze—to engineer a material that retains PTFE's key benefits while dramatically enhancing its mechanical strength.

Why Virgin PTFE Needs Reinforcement

To understand the solution, we must first appreciate the problem. Pure, or "virgin," PTFE has a unique combination of properties, but its mechanical limitations often prevent its use in demanding applications.

The Inherent Weaknesses of Unfilled PTFE

Unfilled PTFE is exceptionally soft compared to other engineering plastics like PEEK or PPS. This leads to several performance issues under mechanical stress.

Key limitations include a high rate of wear, low tensile strength, and a high susceptibility to creep, which is the tendency of a solid material to deform permanently under the influence of persistent mechanical stresses.

The Core Advantages Worth Preserving

Despite its softness, engineers choose PTFE for its unparalleled characteristics. The goal of adding fillers is to overcome its weaknesses without sacrificing these core strengths.

These advantages include being almost universally non-reactive and corrosion-resistant, completely waterproof, and possessing an extremely low coefficient of friction, making it a famously non-stick surface.

The Solution: Compounding with Fillers

Adding a percentage of a reinforcing filler material into the raw PTFE resin during processing creates a composite known as filled PTFE. Each filler imparts a different set of properties.

Glass Fiber Fillers

Glass is one of the most common fillers used for PTFE. It is primarily added to reduce deformation under load and improve durability.

The primary benefits of adding glass fibers are a significant increase in wear resistance and a marked reduction in material creep.

Carbon and Graphite Fillers

Carbon and graphite are often used to enhance a different set of physical properties beyond simple hardness.

These fillers dramatically improve thermal conductivity, allowing heat to dissipate from the surface more effectively. They also improve friction properties and can provide electrical conductivity for static dissipation.

Bronze Fillers

For applications requiring high strength and the ability to withstand heavy loads, bronze is an excellent choice.

Bronze fillers substantially increase compressive strength and hardness. This makes bronze-filled PTFE ideal for components like bearings and wear rings that operate under high pressure.

Molybdenum Disulfide (Moly) Fillers

Molybdenum disulfide, often called "moly," is a dry lubricant that works well in combination with other fillers.

It is typically added to enhance mechanical strength and further improve wear resistance, creating a synergistic effect with fillers like glass or bronze.

Understanding the Trade-offs

Modifying PTFE is not without its compromises. Introducing a filler material will invariably alter some of virgin PTFE's original properties, which must be considered during material selection.

Impact on Chemical Resistance

While the PTFE base remains highly inert, the filler material may not be. Bronze-filled PTFE, for instance, will not have the same resistance to acids or other corrosive chemicals as virgin PTFE.

Changes in Electrical Properties

Virgin PTFE is an excellent electrical insulator. However, adding conductive fillers like carbon or bronze will transform the material into an electrical conductor, making it completely unsuitable for applications requiring insulation.

Abrasiveness to Mating Surfaces

Some fillers, particularly glass fibers, can be abrasive to the surfaces they rub against, especially softer metals like aluminum. This must be factored into the overall system design to prevent premature wear of other components.

Coefficient of Thermal Expansion

All materials expand and contract with temperature changes, and adding fillers will alter PTFE's coefficient of thermal expansion. This is a critical consideration for high-precision components with tight tolerances.

Selecting the Right Filled PTFE for Your Application

The choice of filler should be driven directly by the primary challenge you need to overcome in your specific application.

- If your primary focus is maximum wear resistance and reduced creep: Glass-filled PTFE is the most common and effective starting point.

- If your primary focus is thermal management or static dissipation: Carbon or graphite-filled PTFE provides the necessary thermal and electrical conductivity.

- If your primary focus is high compressive strength for load-bearing: Bronze-filled PTFE offers the best performance under heavy, continuous pressure.

- If your primary focus is a blend of mechanical strength and low friction: A compound including Molybdenum Disulfide can provide a balanced improvement.

By understanding the role of these fillers, you can engineer a PTFE component with the precise properties your demanding application requires.

Summary Table:

| Filler Type | Primary Benefits | Ideal For |

|---|---|---|

| Glass Fiber | Increased wear resistance, reduced creep | General wear parts, seals, bearings |

| Carbon/Graphite | Improved thermal conductivity, static dissipation | Heat management, electrical applications |

| Bronze | High compressive strength, hardness | Heavy-load bearings, wear rings |

| Molybdenum Disulfide | Enhanced mechanical strength, low friction | High-strength, low-wear components |

Need a custom PTFE component that balances hardness with chemical resistance?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. By leveraging filled PTFE compounds, we can engineer a solution that delivers the mechanical strength your demanding application requires while preserving the critical properties of PTFE.

We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications. Contact our experts today to discuss your project and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications