To process Teflon (PTFE) into finished parts, you must use methods that accommodate its unique thermal properties. The two primary techniques are compression molding for simpler shapes and CNC machining for creating complex, high-precision components. Unlike most plastics, PTFE cannot be injection molded because it does not truly melt and flow when heated.

The core challenge in processing PTFE is its inability to be melt-processed like a typical thermoplastic. Its molecular structure requires mechanical shaping (machining) or powder consolidation (molding) rather than a liquid-phase process like injection molding.

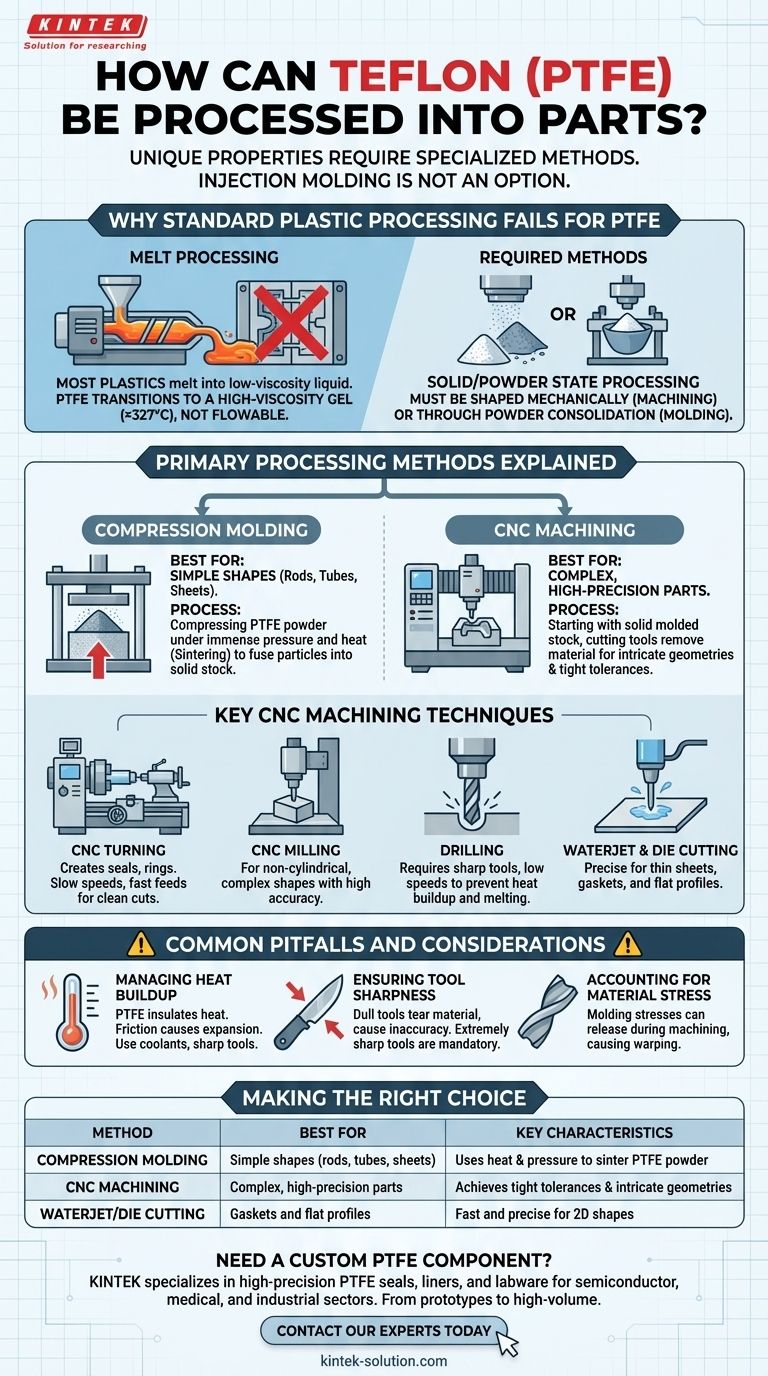

Why Standard Plastic Processing Fails for PTFE

Understanding why PTFE requires special handling is key to selecting the right manufacturing method. Its value comes from a unique set of properties, but these same properties dictate its processing limitations.

A Unique Thermal Response

Most thermoplastics melt into a low-viscosity liquid that can be easily injected into a mold. PTFE behaves differently.

When heated past its melting point (around 327°C), it does not become a free-flowing liquid. Instead, it transitions into a high-viscosity, translucent gel that cannot be forced into the intricate channels of an injection mold.

The Impact on Manufacturing

This behavior renders melt-processing techniques like injection molding and extrusion ineffective. Attempting to process PTFE this way results in failed parts and equipment damage.

Consequently, manufacturers must rely on methods that shape PTFE in its solid or powdered state.

Primary Processing Methods Explained

The right method depends entirely on the part's geometry, required precision, and production volume.

Compression Molding

Compression molding is ideal for producing simple, standard shapes like rods, tubes, and sheets, which are often used as "near-net" stock for subsequent machining.

The process involves compressing PTFE powder in a mold under immense pressure and heat (a process called sintering) to fuse the particles together into a solid, dense block.

CNC Machining

For any part requiring tight tolerances, complex geometries, or intricate features, CNC machining is the definitive method. It involves starting with a solid block or rod of molded PTFE and using computer-controlled cutting tools to remove material.

Various specialized machining operations are used to achieve the final part shape.

Key CNC Machining Techniques for PTFE

- CNC Turning: Used to create cylindrical parts like seals, rings, and connectors. The process typically requires slow speeds and fast feeds to manage heat and achieve a clean cut.

- CNC Milling: Essential for producing complex, non-cylindrical shapes with high accuracy, such as custom blocks, insulators, or component housings.

- Drilling: Requires sharp, specialized drills (like parabolic flutes) and low rotational speeds to prevent heat buildup, which can cause the material to melt and deform around the hole.

- Waterjet & Die Cutting: These methods are highly effective for cutting precise shapes from thin PTFE sheets or thicker plates, commonly used for making gaskets and seals.

Common Pitfalls and Considerations

Machining PTFE is not without its challenges. Its unique properties require specific knowledge and tooling to avoid common failures.

Managing Heat Buildup

PTFE is an excellent thermal insulator, which means it doesn't dissipate heat quickly. Friction from cutting tools can easily build up, causing the material to expand or deform, ruining dimensional accuracy.

Using sharp tools, appropriate coolants, and optimized feeds and speeds is critical to manage this effect.

Ensuring Tool Sharpness

Dull tools will not cut PTFE cleanly. Instead, they will push and tear the material, leading to a poor surface finish and inaccurate dimensions. Extremely sharp, single-point cutting tools are mandatory.

Accounting for Material Stress

The compression molding process used to create the raw PTFE stock can leave internal stresses. Improper machining can release these stresses unevenly, causing the finished part to warp over time.

Making the Right Choice for Your Part

Selecting the optimal processing method is a matter of aligning the technique with the component's final requirements.

- If your primary focus is producing simple stock shapes like rods or sheets: Compression molding is the correct and most economical starting point.

- If your primary focus is creating complex, high-precision parts like custom valves or gears: CNC machining is the only viable method to achieve the necessary detail and tolerances.

- If your primary focus is fabricating gaskets or flat profiles from sheet material: Die cutting or waterjet cutting offers the best combination of speed and precision.

Choosing the right process is the first step in leveraging PTFE's exceptional chemical resistance, low friction, and high-temperature stability in your application.

Summary Table:

| Processing Method | Best For | Key Characteristics |

|---|---|---|

| Compression Molding | Simple shapes (rods, tubes, sheets) | Uses heat and pressure to sinter PTFE powder |

| CNC Machining | Complex, high-precision parts | Achieves tight tolerances and intricate geometries |

| Waterjet/Die Cutting | Gaskets and flat profiles from sheet stock | Fast and precise for 2D shapes |

Need a custom PTFE component? KINTEK specializes in manufacturing high-precision PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments