In short, PTFE rotary shaft seals contribute to operational efficiency and cost savings by dramatically reducing equipment downtime and maintenance needs. Their superior durability and resistance to harsh operating conditions—such as high temperatures, aggressive chemicals, and high speeds—mean they fail less often, last longer, and protect the machinery they are installed in, delivering a clear return on investment.

While conventional seals often represent a recurring maintenance liability, PTFE seals are an engineering asset. They transform the challenge of sealing in demanding environments into a source of long-term reliability and significant cost savings.

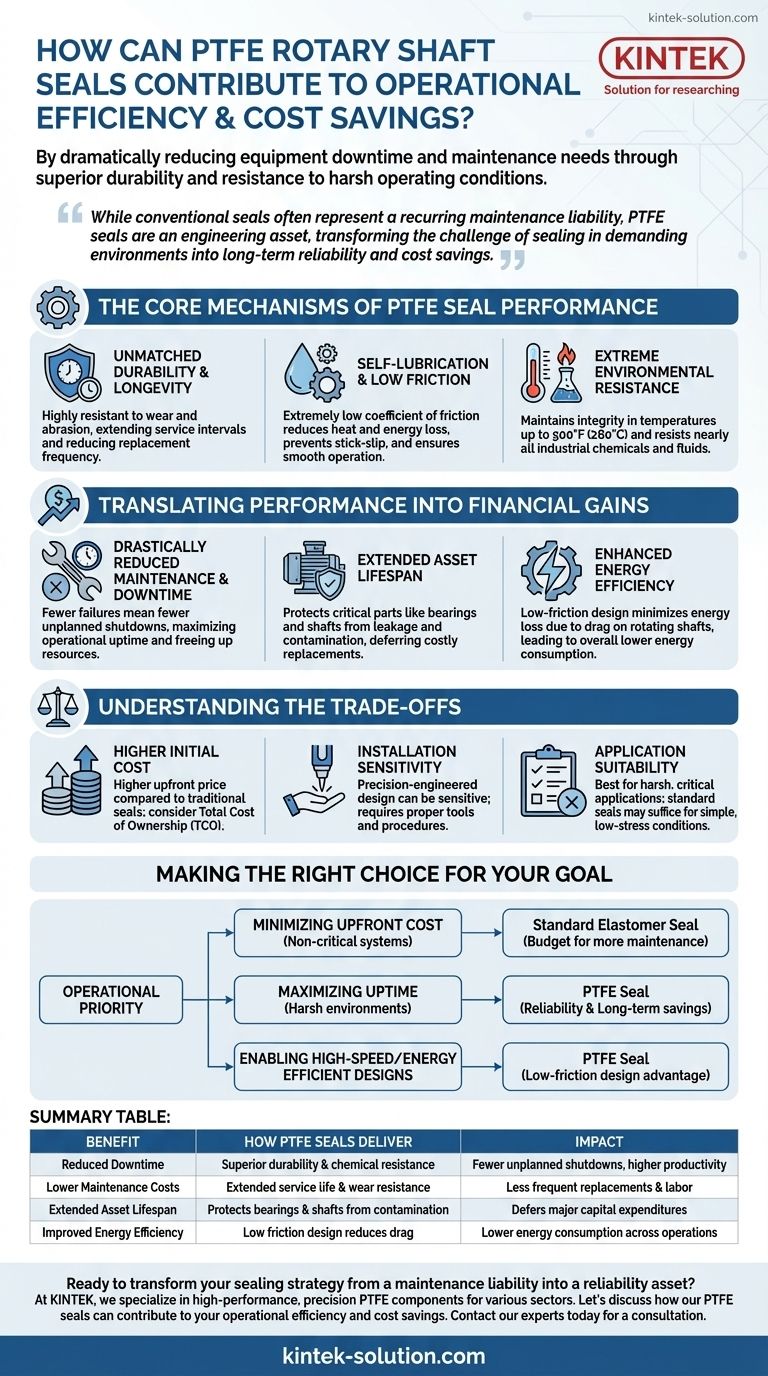

The Core Mechanisms of PTFE Seal Performance

To understand the financial benefits, you must first understand the material science. Polytetrafluoroethylene (PTFE) possesses a unique combination of properties that traditional elastomer seals cannot match, especially when operating conditions become challenging.

Unmatched Durability and Longevity

PTFE is an exceptionally durable material. Seals made from it are highly resistant to wear and abrasion, meaning they do not need to be replaced as frequently.

This inherent toughness directly extends the service interval for your machinery, reducing the long-term costs associated with both replacement parts and the labor required to install them.

Self-Lubrication and Low Friction

A key advantage of PTFE is its extremely low coefficient of friction. This property makes the seals self-lubricating, which is critical in applications with insufficient lubrication or even in dry-running conditions.

This low friction reduces heat generation, minimizes energy loss from the rotating shaft, and prevents the "stick-slip" phenomenon that can cause premature wear and jerky operation. This translates to higher energy efficiency and smoother performance.

Extreme Environmental Resistance

PTFE is renowned for its resilience. It maintains its integrity and sealing capability across a wide range of hostile environments.

Key resistances include:

- High Temperatures: PTFE can operate reliably at temperatures up to 500°F (260°C), where many conventional seals would degrade and fail.

- Chemical Inertness: The material is resistant to nearly all industrial chemicals and fluids, preventing degradation and ensuring a secure seal with aggressive media.

- High Surface Speeds: PTFE seals are dimensionally stable and durable enough to handle high-speed rotary applications without premature wear.

Translating Performance into Financial Gains

The technical advantages of PTFE seals create direct and indirect financial benefits that compound over the life of the equipment.

Drastically Reduced Maintenance and Downtime

This is the most significant source of cost savings. Seal failure leads to unplanned downtime, which halts production and incurs massive costs.

Because PTFE seals are more reliable and last longer, they prevent these costly interruptions. Scheduled maintenance becomes less frequent, freeing up resources and maximizing operational uptime.

Extended Asset Lifespan

A rotary shaft seal's primary job is to prevent leakage and block contamination. When a seal performs this job reliably, it protects the most critical and expensive components of the machinery, such as bearings and shafts.

By preventing the ingress of dirt, water, and other contaminants, PTFE seals extend the life of the entire asset, deferring major capital expenditures on equipment replacement or overhaul.

Enhanced Energy Efficiency

In large-scale industrial operations, even small efficiency gains are valuable. The low-friction nature of PTFE seals means less energy is wasted overcoming drag on the rotating shaft.

While the savings per seal may be minor, across a facility with hundreds of motors, pumps, and gearboxes, this contributes to a noticeable reduction in overall energy consumption.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. An objective analysis requires acknowledging their limitations.

Higher Initial Cost

PTFE seals typically have a higher upfront purchase price compared to traditional nitrile or Viton elastomer seals. The decision to use them requires a total cost of ownership (TCO) analysis, weighing the initial expense against the long-term savings from reduced downtime and maintenance.

Installation Sensitivity

The design that gives PTFE seals their high performance—often a precision-engineered lip—can be more sensitive to damage during installation than a flexible rubber seal. Proper tools and procedures are essential to ensure the seal is not compromised from the start.

Application Suitability

For simple, low-stress, and non-critical applications with stable temperatures and friendly media, a standard elastomer seal may be the more cost-effective choice. The premium performance of PTFE is most valuable where other materials fail.

Making the Right Choice for Your Goal

Your sealing strategy should align directly with your operational priorities.

- If your primary focus is minimizing upfront cost for non-critical systems: A standard elastomer seal may be sufficient, but you must budget for more frequent maintenance and potential downtime.

- If your primary focus is maximizing uptime in harsh environments: The reliability and longevity of PTFE seals provide a clear return on investment by preventing costly failures in high-heat or chemically aggressive applications.

- If your primary focus is enabling high-speed or energy-efficient designs: The unique low-friction and self-lubricating properties of PTFE are a key design advantage that traditional seals cannot offer.

Ultimately, choosing a PTFE seal is a strategic decision to prioritize long-term operational reliability and total cost of ownership over short-term component costs.

Summary Table:

| Benefit | How PTFE Seals Deliver | Impact |

|---|---|---|

| Reduced Downtime | Superior durability & chemical resistance | Fewer unplanned shutdowns, higher productivity |

| Lower Maintenance Costs | Extended service life & wear resistance | Less frequent replacements & labor |

| Extended Asset Lifespan | Protects bearings & shafts from contamination | Defers major capital expenditures |

| Improved Energy Efficiency | Low friction design reduces drag | Lower energy consumption across operations |

Ready to transform your sealing strategy from a maintenance liability into a reliability asset?

At KINTEK, we specialize in manufacturing high-performance, precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get a sealing solution engineered for your specific operating conditions and efficiency goals.

Let's discuss how our PTFE seals can contribute to your operational efficiency and cost savings. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications