To enhance the properties of Polytetrafluoroethylene (PTFE), fillers are incorporated into the base polymer to create PTFE compounds. This process dramatically improves mechanical characteristics like wear resistance, creep strength, and rigidity, overcoming the primary limitations of virgin PTFE while retaining its core benefits.

While virgin PTFE is unparalleled in its chemical resistance, temperature stability, and low-friction surface, its low mechanical strength is a significant drawback. Adding specific fillers is a targeted engineering strategy to reinforce these mechanical weaknesses for demanding applications.

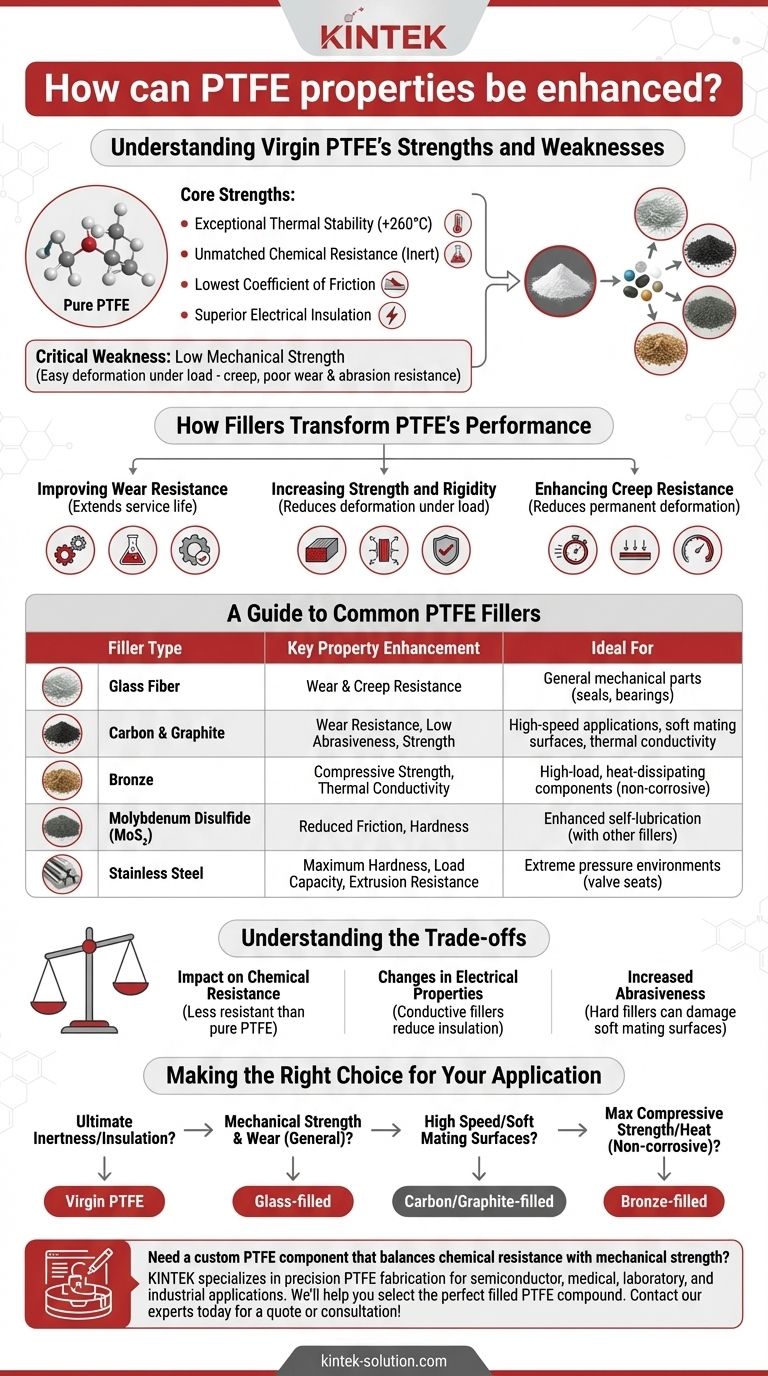

Understanding Virgin PTFE's Strengths and Weaknesses

To appreciate why fillers are necessary, we must first understand the unique profile of pure, or "virgin," PTFE. It possesses a set of exceptional properties that make it a cornerstone material in many industries.

The Core Strengths

Virgin PTFE is renowned for its exceptional performance in several key areas. Its chemical structure results in properties that are difficult to replicate.

- Exceptional Thermal Stability: PTFE has a very high continuous working temperature of up to +260°C (+500°F), the highest among common fluoroplastics. It also maintains flexibility at cryogenic temperatures.

- Unmatched Chemical Resistance: It is almost completely chemically inert and is not affected by the vast majority of industrial chemicals, making it ideal for corrosive environments.

- Lowest Coefficient of Friction: PTFE boasts one of the lowest coefficients of friction of any known solid material, giving it its famous non-stick and excellent sliding properties.

- Superior Electrical Insulation: With very high dielectric strength and electrical resistance, PTFE is a top-tier insulator, especially for high-frequency applications like cables and circuit boards.

The Critical Weakness: Low Mechanical Strength

Despite its remarkable strengths, virgin PTFE has one primary limitation that restricts its use in structural roles.

It has inherently low mechanical strength and rigidity. This means it can deform easily under load (a phenomenon known as creep) and has poor resistance to wear and abrasion.

How Fillers Transform PTFE's Performance

Fillers are specific materials added to the raw PTFE powder before it is processed and sintered. These additives create a composite material, or compound, that physically reinforces the PTFE matrix.

Improving Wear Resistance

This is the most common reason for using filled PTFE. Fillers interrupt the material's tendency to wear away, extending the service life of components like seals, bearings, and wear pads.

Increasing Strength and Rigidity

Fillers add a structural backbone to the soft PTFE matrix. This significantly reduces deformation under load, allowing PTFE parts to maintain their shape and tolerances under pressure.

Enhancing Creep Resistance

By reinforcing the material, fillers drastically reduce the tendency of PTFE to slowly and permanently deform when subjected to a constant load, a critical factor for seals and gaskets.

A Guide to Common PTFE Fillers

The choice of filler is determined by the specific performance gap you need to close. Each filler imparts a unique set of properties to the final compound.

Glass Fiber

This is one of the most common fillers. It provides a significant increase in wear resistance and creep resistance compared to virgin PTFE. It is a great all-around choice for many mechanical applications.

Carbon and Graphite

These fillers dramatically improve wear resistance, strength, and load-bearing capabilities. They are an excellent choice for applications with high speeds or for use against soft metal surfaces, as they are less abrasive than glass. They also improve thermal conductivity.

Bronze

Bronze provides excellent compressive strength and thermal conductivity, making it suitable for applications that require high load capacity and heat dissipation. However, it has poor chemical resistance compared to other fillers.

Molybdenum Disulfide (MoS₂)

Often used in combination with other fillers, MoS₂ improves hardness and further reduces the coefficient of friction, enhancing the self-lubricating properties of the compound.

Stainless Steel

For extreme applications, stainless steel fillers provide maximum hardness, load-bearing capacity, and extrusion resistance. This is ideal for components like valve seats that operate under very high pressure.

Understanding the Trade-offs

Enhancing one property with a filler often means compromising another. This is a fundamental principle of materials science that must be considered.

Impact on Chemical Resistance

Fillers are almost always less chemically resistant than pure PTFE. A glass-filled compound can be attacked by strong alkalis, and a bronze-filled compound is susceptible to corrosion.

Changes in Electrical Properties

The outstanding electrical insulating properties of PTFE are compromised by conductive fillers. Carbon and metallic fillers (bronze, steel) will significantly reduce the material's electrical resistance, making them unsuitable for insulating applications.

Increased Abrasiveness

Hard fillers like glass fiber can be abrasive to softer mating surfaces, such as aluminum or certain plastics. In these scenarios, a less abrasive filler like carbon/graphite is a superior choice to prevent damage to other components.

Making the Right Choice for Your Application

The decision to use virgin or filled PTFE depends entirely on the specific demands of your operating environment.

- If your primary focus is ultimate chemical inertness or electrical insulation: Virgin PTFE is the correct choice, provided the mechanical demands are low.

- If your primary focus is mechanical strength and wear resistance in a general environment: A glass-filled compound offers the best price-to-performance ratio.

- If your application involves high speeds or soft mating surfaces: A carbon/graphite-filled compound will provide excellent wear resistance without damaging adjacent parts.

- If your primary focus is maximum compressive strength and heat dissipation: A bronze-filled compound is ideal, but only in non-corrosive environments.

By understanding these principles, you can select the precise PTFE formulation to meet your specific engineering challenge.

Summary Table:

| Filler Type | Key Property Enhancement | Ideal For |

|---|---|---|

| Glass Fiber | Wear & Creep Resistance | General mechanical parts (seals, bearings) |

| Carbon/Graphite | Wear Resistance, Low Abrasiveness | High-speed applications, soft mating surfaces |

| Bronze | Compressive Strength, Thermal Conductivity | High-load, heat-dissipating components |

| Molybdenum Disulfide | Reduced Friction, Hardness | Enhanced self-lubrication |

| Stainless Steel | Maximum Hardness, Load Capacity | Extreme pressure environments (valve seats) |

Need a custom PTFE component that balances chemical resistance with mechanical strength? KINTEK specializes in precision PTFE fabrication—from prototypes to high-volume orders—for semiconductor, medical, laboratory, and industrial applications. We’ll help you select the perfect filled PTFE compound (glass, carbon, bronze, and more) to solve your unique engineering challenge. Contact our experts today for a quote or consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments