To minimize deformation when machining Teflon (PTFE), you must use extremely sharp tools, manage heat with a coolant, and secure the workpiece without applying excessive clamping pressure. These three actions directly counteract Teflon's inherent softness, its high rate of thermal expansion, and its tendency to slip or creep under stress.

The core challenge of machining Teflon is not cutting the material, but controlling its physical response to pressure and heat. Success depends on adapting your technique to manage its softness, slipperiness, and extreme thermal sensitivity.

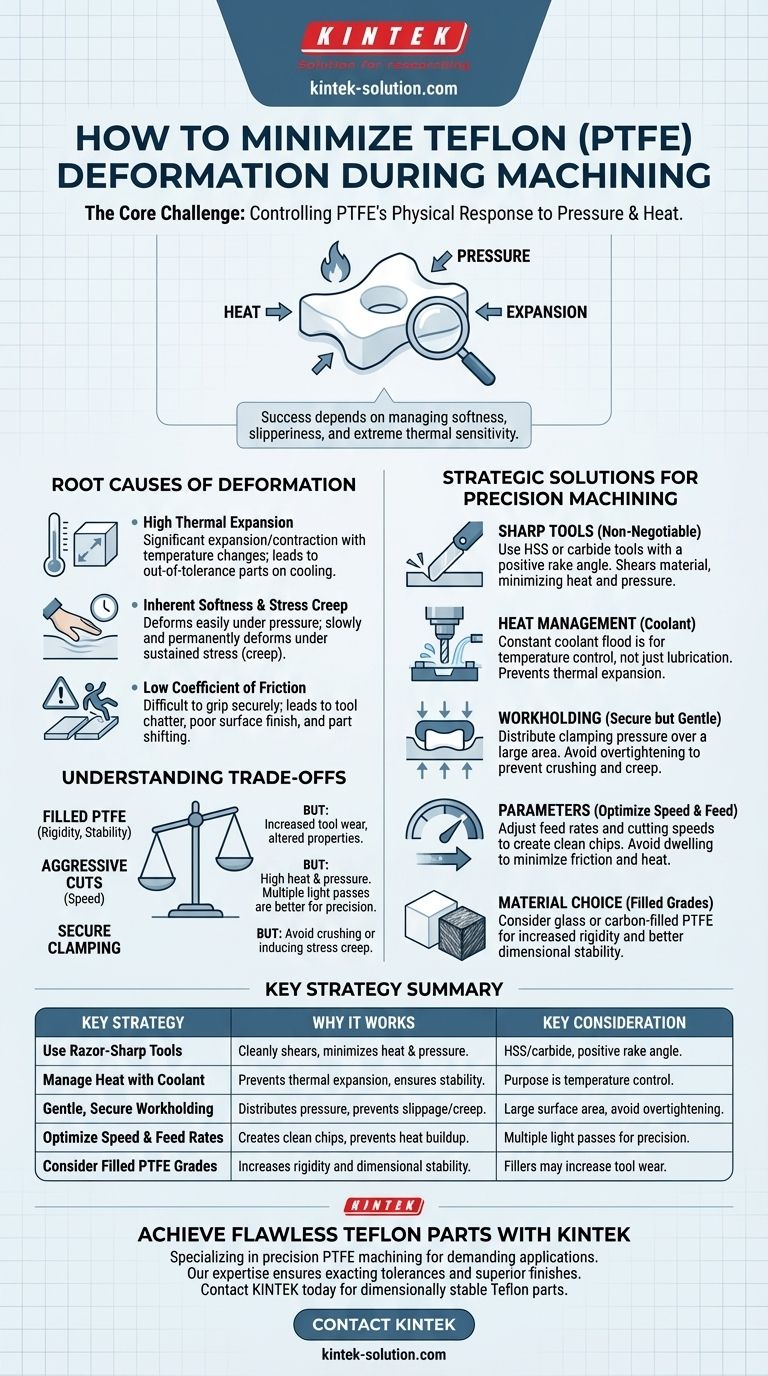

The Root Causes of Teflon Deformation

Understanding why Teflon deforms is the first step toward preventing it. The material's unique properties are the source of most machining challenges.

High Coefficient of Thermal Expansion

Teflon expands and contracts significantly with even minor temperature changes. The heat generated by a cutting tool is often enough to make the material expand during the cut, only for it to shrink and fall out of tolerance as it cools.

Inherent Softness and Stress Creep

PTFE is an exceptionally soft material. It easily deforms under the pressure of both the cutting tool and the clamping fixture. Furthermore, it exhibits stress creep, meaning it will slowly and permanently deform if held under pressure for an extended period.

Low Coefficient of Friction

While its "slipperiness" is a key benefit in finished products, it makes the material difficult to grip securely during machining. This can lead to tool chatter, poor surface finish, and parts shifting in the fixture, ruining precision.

Strategic Solutions for Precision Machining

A successful strategy for machining Teflon involves a series of deliberate choices that respect its material properties.

Tooling: Sharpness is Non-Negotiable

Your single most important tool is a sharp cutting edge. A dull tool will push and smear the material rather than shear it, generating excess heat and pressure that lead to deformation.

Use high-speed steel (HSS) or carbide tools with a very sharp edge and a positive rake angle. This geometry helps lift and slice the chip away cleanly, minimizing force on the part.

Heat Management: The Role of Coolant

The primary purpose of coolant when machining Teflon is temperature control, not lubrication. A steady flood of coolant carries away heat from the cutting zone, preventing thermal expansion and ensuring dimensional stability.

This also serves a critical safety function. If Teflon is heated above 250°C, it can begin to decompose and release toxic gases. Proper cooling keeps temperatures well below this threshold.

Workholding: Secure but Gentle

You must secure the workpiece firmly enough to prevent movement but gently enough to avoid crushing it. Use fixtures with a large surface area to distribute clamping pressure evenly.

Avoid overtightening vises or chucks. The goal is to prevent slipping and chatter without inducing stress creep into the part.

Parameters: Adjusting Speed and Feed

Use appropriate feed rates and cutting speeds to prevent smearing and heat buildup. While specific parameters vary, the principle is to create a clean chip without dwelling in one spot, which generates friction and heat.

For drilling, specialized tools like parabolic flute drills are effective at clearing chips and reducing heat.

Material Choice: Consider Filled Grades

If the application allows, using a "filled" grade of Teflon can dramatically improve machinability. Materials like glass-filled or carbon-filled PTFE are significantly more rigid and less prone to thermal expansion, making it easier to hold tight tolerances.

Understanding the Trade-offs

Every decision in machining involves a balance. Being aware of these trade-offs is crucial for consistent results.

Filled vs. Unfilled Teflon

Adding fillers increases rigidity and dimensional stability, which is excellent for machining. However, these fillers can increase tool wear and may alter the chemical resistance or coefficient of friction of the final part.

Aggressive Cuts vs. Precision

While faster speeds and deeper cuts can improve cycle times, they generate significantly more heat and tool pressure. For high-precision work, multiple light passes are almost always superior to a single heavy cut.

Clamping Pressure vs. Part Security

The balance between holding the part securely and deforming it is delicate. Too little pressure and the part moves; too much and it is crushed. This is often the most difficult variable to master and may require custom fixtures for complex parts.

Making the Right Choice for Your Goal

Your specific objective should guide your machining strategy.

- If your primary focus is achieving the tightest tolerances: Prioritize thermal stability above all. Use a constant flood of coolant, sharp tools that generate minimal heat, and allow the part to normalize to room temperature before taking final measurements.

- If your primary focus is the best possible surface finish: Concentrate on tooling and feed rates. A razor-sharp tool with the correct geometry combined with an optimal feed rate is the only way to prevent smearing.

- If your primary focus is dimensional stability in a challenging shape: Consider using a filled grade of PTFE. The added rigidity will make the material far more forgiving of clamping pressure and heat.

By respecting Teflon's unique properties instead of fighting them, you can achieve precise and repeatable results.

Summary Table:

| Key Strategy | Why It Works | Key Consideration |

|---|---|---|

| Use Razor-Sharp Tools | Cleanly shears material instead of smearing, minimizing heat and pressure. | High-speed steel (HSS) or carbide with a positive rake angle is ideal. |

| Manage Heat with Coolant | Prevents thermal expansion and keeps material below dangerous decomposition temperatures. | Primary purpose is temperature control, not lubrication. |

| Gentle, Secure Workholding | Distributes clamping pressure to prevent part slippage without inducing stress creep. | Use fixtures with large surface area; avoid overtightening. |

| Optimize Speed & Feed Rates | Creates clean chips and prevents heat buildup from friction. | Multiple light passes are better than a single heavy cut for precision. |

| Consider Filled PTFE Grades | Glass or carbon fillers increase rigidity and dimensional stability. | Fillers may increase tool wear and alter final part properties. |

Achieve Flawless Teflon Parts with KINTEK

Struggling with PTFE deformation? You don't have to. KINTEK specializes in the precision machining of Teflon components for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We understand the critical balance required to machine soft, thermally sensitive materials like PTFE. Our expertise ensures your prototypes or high-volume orders are produced with exacting tolerances and superior surface finishes.

Let us put our precision production and custom fabrication skills to work for you.

Contact KINTEK today to discuss your project and get a quote for high-quality, dimensionally stable Teflon parts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials