In the food processing industry, PTFE Teflon washers are primarily used as seals, gaskets, and friction-reducing spacers in equipment that comes into direct contact with food. Their selection is driven by a unique combination of properties: they are FDA-approved for food contact, possess an exceptionally non-stick surface that prevents product buildup, and can withstand the aggressive chemicals and temperatures common in cleaning and sterilization processes.

The core reason for using PTFE washers in food processing is not just about a single feature, but about its ability to simultaneously ensure food safety, operational efficiency, and equipment longevity in a highly regulated and demanding environment.

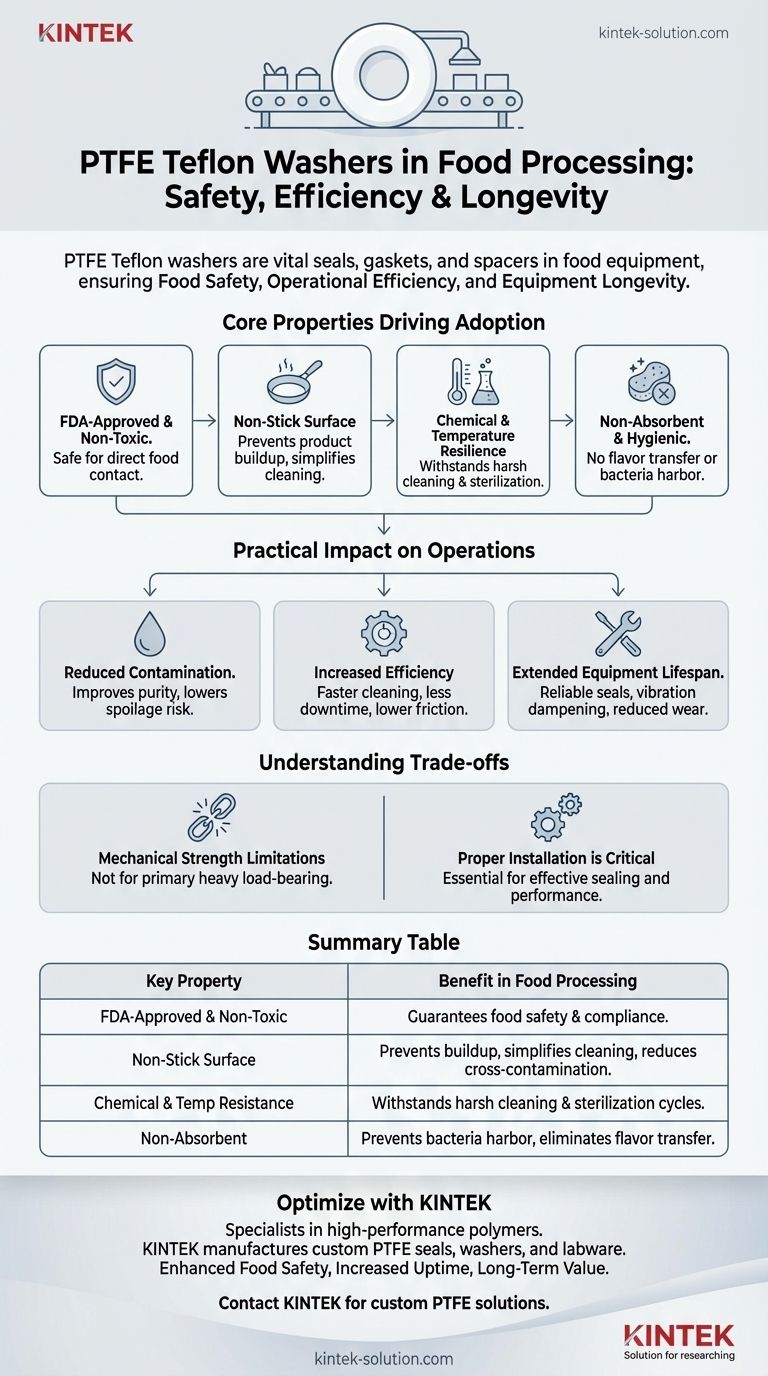

The Core Properties Driving Food Industry Adoption

The suitability of PTFE for food processing is not accidental. It stems from a specific set of inherent material characteristics that directly address the industry's biggest challenges: hygiene, purity, and uptime.

FDA-Approval and Food Safety

The most critical requirement for any material touching food is that it be non-toxic and safe for consumption. PTFE is FDA-approved for food contact, making it a pre-qualified and trusted material for use in processing machinery.

The Non-Stick Advantage

PTFE has one of the lowest coefficients of friction of any solid material, giving it its famous non-stick surface. In food processing, this prevents food particles, syrups, and other viscous materials from adhering to machine components, which is critical for preventing cross-contamination and simplifying cleaning.

Chemical and Temperature Resilience

Food processing environments involve extreme conditions. Equipment must endure everything from acidic products like tomato sauce to caustic cleaning agents and high-temperature sterilization. PTFE is chemically inert and stable across a wide temperature range, ensuring it will not degrade, leach chemicals, or fail during these aggressive cycles.

Non-Absorbency and Hygiene

PTFE is non-absorbent, meaning it does not soak up moisture, oils, or flavors. This property is vital for hygiene, as it prevents the material from harboring bacteria or transferring tastes between different product batches.

The Practical Impact on Food Processing Operations

These material properties translate directly into tangible benefits for a food processing plant, impacting everything from product quality to the bottom line.

Reducing Contamination and Improving Purity

By preventing food from sticking and being non-absorbent, PTFE washers play a direct role in maintaining the purity of the food product. This reduces the risk of spoilage and ensures the final product is free from unwanted residues.

Increasing Operational Efficiency

A non-stick surface means faster and easier cleaning, which significantly reduces equipment downtime. Less friction between moving parts also means machinery operates more smoothly, consuming less energy and requiring less maintenance.

Extending Equipment Lifespan

Used as gaskets and spacers, PTFE washers create reliable seals and dampen vibrations between metal components. This protective barrier prevents leaks and reduces wear and tear on expensive machinery, extending the operational life of the equipment.

Understanding the Trade-offs

While highly effective, it's important to understand the context in which PTFE washers perform best. No material is a universal solution.

Mechanical Strength Limitations

PTFE is a relatively soft material compared to metals. It is ideal for sealing and low-friction applications but is not intended for use as a primary structural component that bears a heavy mechanical load.

Proper Installation is Critical

Like any gasket or seal, the performance of a PTFE washer depends entirely on correct sizing and installation. An improperly fitted washer can fail to seal effectively, negating its benefits and potentially causing leaks or contamination.

Cost vs. Long-Term Value

PTFE components may have a higher initial cost than some simpler rubber or plastic alternatives. However, their durability, contribution to food safety, and the reduction in maintenance downtime often provide a superior long-term return on investment.

Making the Right Choice for Your Application

Selecting the right material is a foundational decision for safe and efficient operations. Your specific goal will determine why PTFE is the appropriate choice.

- If your primary focus is product purity and safety: PTFE's FDA approval and inert, non-stick surface make it the definitive choice for direct food contact points.

- If your primary focus is operational uptime: The material's resilience to harsh cleaning cycles and its non-stick nature reduce maintenance time and prevent costly production delays.

- If your primary focus is handling corrosive or high-temperature goods: PTFE's chemical and thermal stability ensures component integrity when processing acidic foods or undergoing sterilization.

Ultimately, incorporating PTFE Teflon washers is a strategic choice to uphold the highest standards of hygiene while optimizing the productivity of your processing line.

Summary Table:

| Key Property | Benefit in Food Processing |

|---|---|

| FDA-Approved & Non-Toxic | Guarantees food safety and compliance for direct contact applications. |

| Non-Stick Surface | Prevents product buildup, simplifies cleaning, and reduces cross-contamination. |

| Chemical & Temperature Resistance | Withstands harsh cleaning agents and high-temperature sterilization cycles. |

| Non-Absorbent | Prevents harboring bacteria and eliminates flavor transfer between batches. |

Optimize your food processing equipment with precision-engineered PTFE components from KINTEK.

As specialists in high-performance polymers, KINTEK manufactures custom PTFE seals, washers, and labware for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical need for reliability and purity in the food processing industry.

By choosing KINTEK, you benefit from:

- Enhanced Food Safety: Our FDA-compliant PTFE components ensure product purity.

- Increased Uptime: Reduce maintenance and cleaning cycles with superior non-stick properties.

- Long-Term Value: Durable components that extend equipment lifespan and provide a strong return on investment.

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss how our PTFE solutions can improve the safety and efficiency of your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech