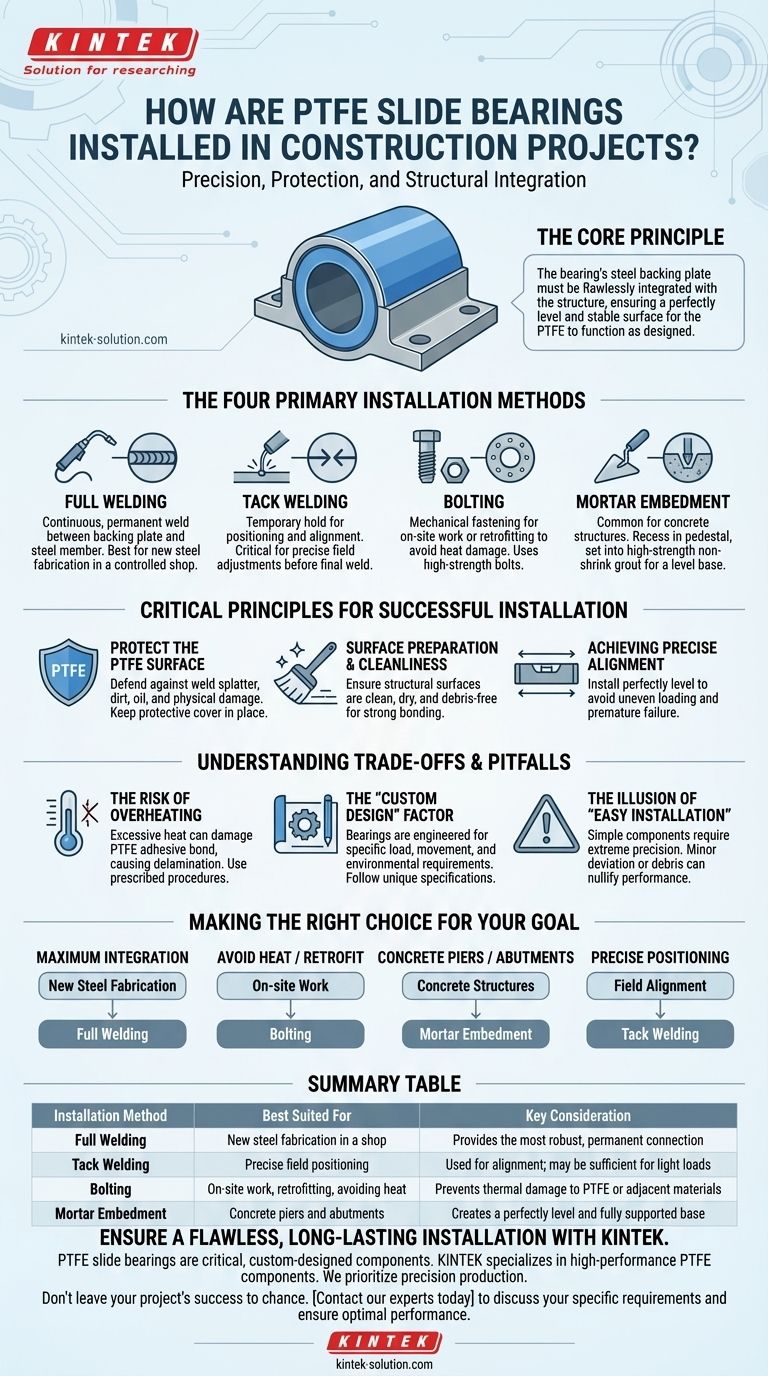

For construction projects, PTFE slide bearings are typically installed using one of four primary methods: full welding, tack welding, bolting, or embedding in mortar. The success of any method depends entirely on meticulous surface preparation, precise alignment, and rigorously protecting the sensitive PTFE surface from damage or contamination during the process.

The specific installation method is secondary to the underlying principle: the bearing's steel backing plate must be flawlessly integrated with the structure, ensuring a perfectly level and stable surface for the PTFE to function as designed.

The Four Primary Installation Methods

Each installation technique is suited for different structural materials and site conditions. The choice is dictated by the engineering plans, which consider the type of structure (steel or concrete), load requirements, and construction environment.

Full Welding

Full welding involves creating a continuous, permanent weld between the steel backing plate of the bearing and the steel structural member. This method creates the most robust, fully integrated connection. It is typically performed in a fabrication shop where conditions can be controlled.

Tack Welding

Tack welding is used to temporarily hold a bearing in place for positioning and alignment before the final, full weld is applied. In some lighter-duty applications, tack welds may be sufficient as the permanent connection, but this must be explicitly approved by the project engineer.

Bolting

Bolting is a common mechanical fastening method used when welding is impractical or undesirable, such as in areas where heat from welding could damage adjacent materials or coatings. The bearing's backing plate is manufactured with pre-drilled holes to accept high-strength bolts that secure it to the structure.

Mortar Embedment

When installing bearings on concrete structures, the most common method is mortar embedment. A recess is created in the concrete pedestal, and the bearing is set into a bed of high-strength, non-shrink grout or mortar, ensuring a perfectly level and fully supported base.

Critical Principles for a Successful Installation

The long-term performance and "maintenance-free" nature of a PTFE bearing are not inherent to the product itself; they are a direct result of a flawless installation. Failure to adhere to these principles will compromise the system.

Protecting the PTFE Surface

The low-friction PTFE surface is the core of the bearing. It must be protected from weld splatter, dirt, oil, and physical damage at all times. Bearings are often shipped with a protective cover that should remain in place for as long as possible during construction.

Surface Preparation and Cleanliness

The structural surfaces where the bearing will be installed must be completely clean, dry, and free of debris. For welded or bolted connections, the steel must be prepared according to structural welding or bolting codes. For mortar embedment, the concrete surface must be sound and properly prepared to ensure a strong bond.

Achieving Precise Alignment

The bearing must be installed perfectly level and aligned according to the structural plans. Any misalignment can cause uneven loading on the PTFE surface, leading to premature wear and failure of the bearing. This is why tack welding and careful leveling with grout are such critical steps.

Understanding the Trade-offs and Pitfalls

While the installation process seems straightforward, several common pitfalls can lead to catastrophic failure. Understanding these risks is essential for any installer.

The Risk of Overheating

When welding, excessive heat can transfer through the steel backing plate and damage the adhesive bond holding the PTFE layer. This can cause the PTFE to delaminate, rendering the bearing useless. Installers must use prescribed welding procedures to control heat input.

The "Custom Design" Factor

PTFE bearings are not off-the-shelf components; they are engineered specifically for each project's load, movement, and environmental requirements. An installer must never assume the process is the same as a previous job. The manufacturer's and engineer's specifications are the only source of truth.

The Illusion of "Easy Installation"

The relative simplicity of the components can create a false sense of security. The ease of installation is contingent upon extreme precision. A deviation of even a small fraction of a degree from level or a single piece of debris under the plate can negate the bearing's high-performance capabilities.

Making the Right Choice for Your Goal

The installation method is always determined by the project's structural engineer. However, understanding the context for each choice is key to proper execution.

- If your primary focus is maximum integration on new steel fabrication: Full welding in a controlled shop environment is the most direct and robust method.

- If you must avoid heat distortion or are retrofitting on-site: Bolting provides a secure mechanical connection without the thermal risks associated with welding.

- If you are installing bearings onto concrete piers or abutments: Mortar embedment is the standard for creating a perfectly level, fully supported load-bearing surface.

- If you require precise field positioning before final attachment: Tack welding allows for critical adjustments before committing to a permanent full weld.

Ultimately, a successful installation is defined by precision and absolute adherence to the engineering specifications, ensuring the bearing functions flawlessly for the life of the structure.

Summary Table:

| Installation Method | Best Suited For | Key Consideration |

|---|---|---|

| Full Welding | New steel fabrication in a shop | Provides the most robust, permanent connection |

| Tack Welding | Precise field positioning before a final weld | Used for alignment; may be sufficient for light loads |

| Bolting | On-site work, retrofitting, avoiding heat | Prevents thermal damage to PTFE or adjacent materials |

| Mortar Embedment | Concrete piers and abutments | Creates a perfectly level and fully supported base |

Ensure a flawless, long-lasting installation with precision-engineered PTFE bearings from KINTEK.

PTFE slide bearings are critical, custom-designed components. Their promised 'maintenance-free' performance is only achieved through perfect installation. KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, labware, and custom bearings—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders. By choosing KINTEK, you get a partner dedicated to the quality and reliability your project demands.

Don't leave your project's success to chance. Contact our experts today to discuss your specific requirements and ensure your PTFE bearings are installed for optimal performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials