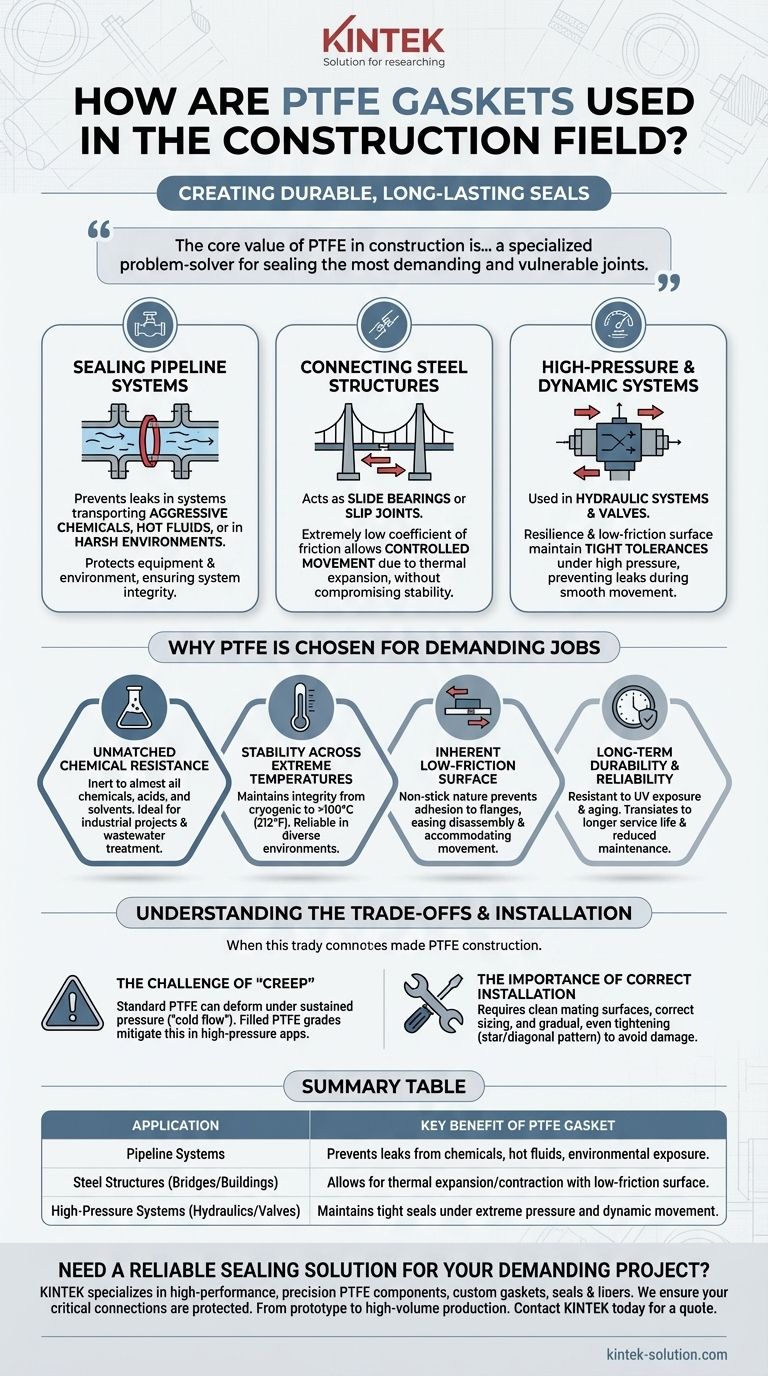

In construction, PTFE gaskets are primarily used to create durable, long-lasting seals in pipeline systems and structural steel connections, especially where there is exposure to corrosive materials, extreme temperatures, or a need to accommodate slight movement. Their unique properties ensure the stability, safety, and reliability of these critical connection points.

The core value of PTFE in construction is not as a general-purpose sealant, but as a specialized problem-solver. Its unparalleled resistance to chemicals, temperature, and friction makes it the definitive choice for sealing the most demanding and vulnerable joints in a structure.

Core Applications in Construction Environments

Polytetrafluoroethylene (PTFE) is engineered for performance in harsh conditions, making it suitable for specific, high-stakes applications within the construction field.

Sealing Pipeline Systems

PTFE gaskets are essential for connecting and sealing pipe flanges. This is particularly true for systems that transport aggressive chemicals, hot fluids, or are exposed to outdoor environmental conditions.

Their purpose is to prevent leaks, which protects both the equipment and the environment, ensuring the long-term integrity of the entire pipeline system.

Connecting Steel Structures

In large steel structures like bridges or buildings, PTFE is used not just as a sealant but also as a slide bearing or slip joint material. Its extremely low coefficient of friction is a significant advantage here.

These gaskets or pads allow for controlled, minute movements caused by thermal expansion and contraction without compromising the stability or seal of the connection point.

High-Pressure and Dynamic Systems

PTFE seals are also found within hydraulic systems, valves, and other dynamic components used in construction machinery or integrated into a building's mechanical systems.

Here, the material's resilience and low-friction surface maintain tight tolerances, ensuring smooth movement between parts while preventing fluid or gas leaks under high pressure.

Why PTFE Is Chosen for Demanding Jobs

The selection of PTFE over more common gasket materials is a deliberate engineering decision based on its unique combination of properties.

Unmatched Chemical Resistance

PTFE is virtually inert and resistant to almost all chemicals, acids, and solvents. This makes it ideal for industrial construction or infrastructure projects involving wastewater treatment, chemical processing, or exposure to environmental pollutants.

Stability Across Extreme Temperatures

PTFE gaskets maintain their integrity and sealing capability across a very wide temperature range. They are a reliable choice for applications exposed to everything from cryogenic temperatures to service temperatures exceeding 100°C (212°F).

Inherent Low-Friction Surface

The material's non-stick, low-friction nature is a key mechanical advantage. It prevents the gasket from adhering to flange surfaces, making disassembly easier and reducing the stress on connection points that need to accommodate movement.

Long-Term Durability and Reliability

PTFE is highly resistant to aging and degradation from UV exposure. This translates to a longer service life and reduced maintenance requirements for critical infrastructure, improving overall safety and lowering lifetime costs.

Understanding the Trade-offs and Installation

While highly effective, PTFE is not a universal solution. Understanding its limitations and proper handling is critical to achieving a successful outcome.

The Challenge of "Creep"

Standard, unfilled PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms over time under sustained pressure. This can lead to a loss of bolt torque and a potential leak. For high-pressure applications, filled PTFE grades are often used to mitigate this effect.

The Importance of Correct Installation

The performance of any gasket is heavily dependent on proper installation. Mating surfaces must be perfectly clean and free of defects.

Technicians must ensure the gasket is correctly sized and aligned with the flange faces. Bolts should be tightened gradually and evenly in a star or diagonal pattern to distribute pressure uniformly, avoiding over-tightening which can damage the gasket.

Making the Right Choice for Your Project

Selecting the appropriate gasket material is fundamental to the safety and longevity of the final structure.

- If your primary focus is sealing critical pipelines with chemical or high-temperature exposure: PTFE's inertness and thermal stability make it an ideal and often necessary choice.

- If your primary focus is accommodating thermal movement in large steel structures: The low-friction properties of PTFE are a distinct advantage for slide bearings and expansion joints.

- If your primary focus is a standard, low-pressure water or air line in a controlled environment: A less expensive, more traditional gasket material like EPDM or neoprene is likely a more cost-effective solution.

Ultimately, choosing the right material for the specific application is a foundational step in ensuring the long-term integrity and safety of any construction project.

Summary Table:

| Application | Key Benefit of PTFE Gasket |

|---|---|

| Pipeline Systems | Prevents leaks from chemicals, hot fluids, and environmental exposure. |

| Steel Structures (Bridges/Buildings) | Allows for thermal expansion/contraction with its low-friction surface. |

| High-Pressure Systems (Hydraulics/Valves) | Maintains tight seals under extreme pressure and dynamic movement. |

Need a reliable sealing solution for your demanding construction project?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including custom gaskets, seals, and liners—for the semiconductor, medical, laboratory, industrial, and construction sectors. We ensure your critical connections are protected against chemicals, extreme temperatures, and movement.

From prototype to high-volume production, our custom fabrication expertise delivers the durability and reliability your project requires. Contact KINTEK today to discuss your specific application and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support