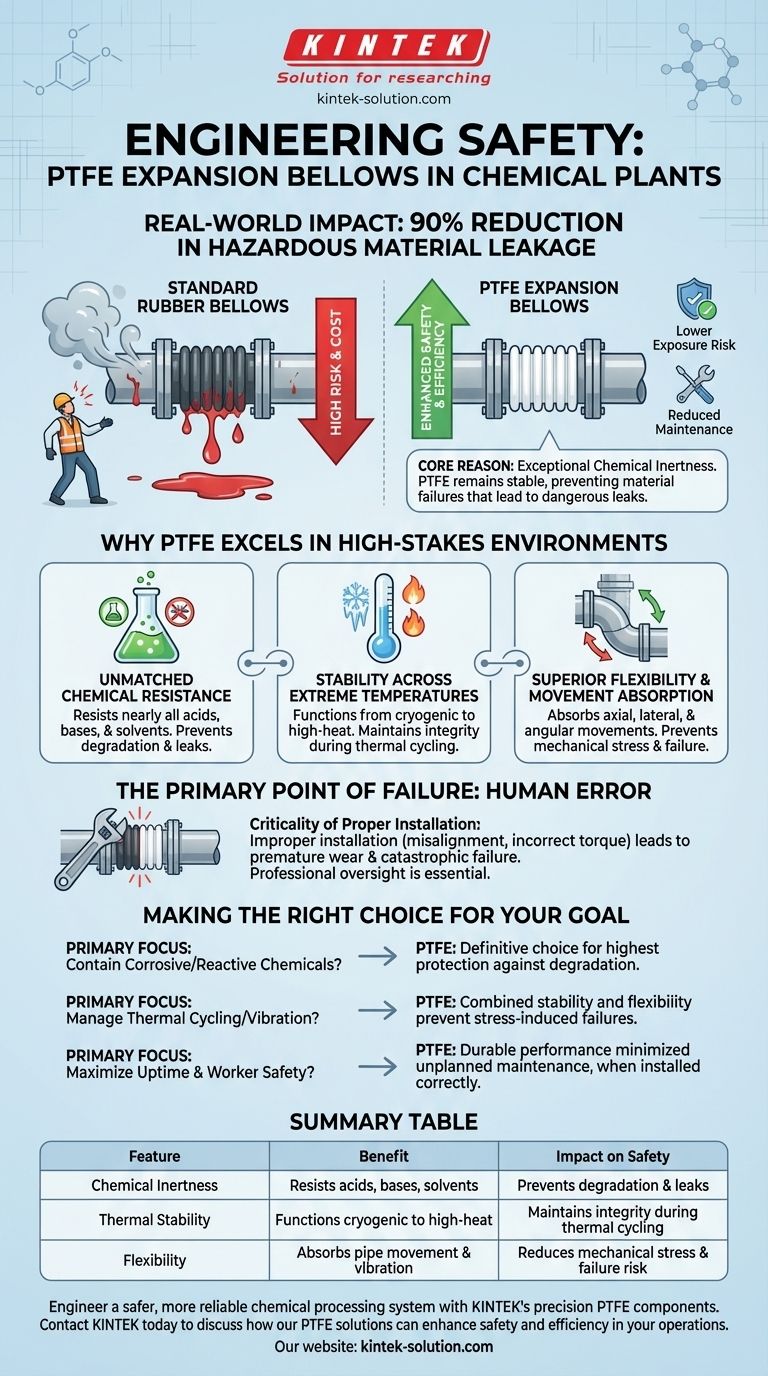

In a real-world chemical processing facility, replacing standard rubber bellows with those made from Polytetrafluoroethylene (PTFE) resulted in a 90% reduction in hazardous material leakage. This single material change directly enhanced worker safety by dramatically lowering the risk of chemical exposure and significantly reduced the operational costs associated with cleanup and maintenance.

The core reason PTFE expansion bellows improve safety is their exceptional chemical inertness. Unlike other materials that degrade upon contact with corrosive substances, PTFE remains stable, preventing the material failures that lead to dangerous leaks and system breaches in critical environments.

Why PTFE Excels in High-Stakes Environments

Understanding the material properties of PTFE reveals why it is the superior choice for safety-critical applications in chemical plants and other demanding industries. Its advantages are not incremental; they are fundamental to system integrity.

Unmatched Chemical Resistance

The primary safety benefit of PTFE is its ability to withstand nearly all acids, bases, solvents, and other aggressive chemicals without degrading.

This chemical inertness means the bellow itself does not become a point of failure when transporting hazardous materials, directly preventing leaks that could harm personnel or the environment.

Stability Across Extreme Temperatures

PTFE bellows function reliably across a vast temperature range, from cryogenic conditions to high-heat processes.

In applications like pharmaceutical sterilization, they endure high temperatures without cracking or losing their seal, ensuring system integrity during thermal cycling that would compromise lesser materials.

Superior Flexibility and Movement Absorption

Piping systems are not static; they move due to thermal expansion, contraction, and machinery vibrations.

PTFE bellows are highly flexible, capable of absorbing axial, lateral, and angular movements. This capability prevents mechanical stress from concentrating at fixed points, a common cause of pipe or flange failure.

Understanding the Primary Point of Failure

While the material itself is exceptionally robust, the safety benefits of PTFE bellows are entirely dependent on one critical factor: installation. The most common cause of failure is not material defect, but human error.

The Criticality of Proper Installation

Improper installation can lead to premature wear and catastrophic failure, negating all the material's inherent advantages.

Key failure points include misalignment with pipelines, incorrect fastener torque during mounting, or failing to provide adequate clearance for the bellow's designed range of motion. Following manufacturer guidelines is not optional; it is essential for safe operation.

A Component Requiring Professional Oversight

Because the integrity of the entire system can depend on a single bellow, it should not be treated as a simple commodity.

Ensuring that installation is performed by trained personnel who understand the precise requirements for alignment and torque is a critical safety control.

Making the Right Choice for Your Goal

Selecting the correct expansion bellow is a foundational decision for ensuring system safety and reliability. Your operational priorities should guide your choice.

- If your primary focus is containing highly corrosive or reactive chemicals: PTFE is the definitive choice, as its chemical resistance provides the highest level of protection against material degradation and leaks.

- If your primary focus is managing systems with significant thermal cycling or vibration: PTFE's combined thermal stability and flexibility are critical for preventing stress-induced failures over the long term.

- If your primary focus is maximizing operational uptime and worker safety: The durability of PTFE minimizes unplanned maintenance, but this is only achieved when paired with strict adherence to professional installation protocols.

Ultimately, choosing the right material is the first and most critical step in engineering a safer industrial system.

Summary Table:

| Feature | Benefit | Impact on Safety |

|---|---|---|

| Chemical Inertness | Resists acids, bases, and solvents | Prevents material degradation and leaks |

| Thermal Stability | Functions from cryogenic to high-heat conditions | Maintains integrity during thermal cycling |

| Flexibility | Absorbs pipe movement and vibration | Reduces mechanical stress and failure risk |

Engineer a safer, more reliable chemical processing system with KINTEK's precision PTFE components.

Our PTFE expansion bellows, seals, liners, and labware are manufactured to the highest standards for the semiconductor, medical, laboratory, and industrial sectors. We combine superior material performance with custom fabrication—from prototypes to high-volume orders—to meet your exact specifications.

Contact KINTEK today to discuss how our PTFE solutions can enhance safety and efficiency in your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability