Absolutely. Beyond cost, several critical engineering and logistical advantages ensure traditional O-rings and gaskets remain the optimal choice for many applications. Their continued prevalence is a result of proven performance, standardization, and unparalleled availability, not simply a concession to budget.

The decision to use a traditional O-ring is not about choosing an "old" technology over a "new" one. It's about selecting the sealing solution with the most predictable, reliable, and easily serviceable performance characteristics for a specific, well-defined operational context.

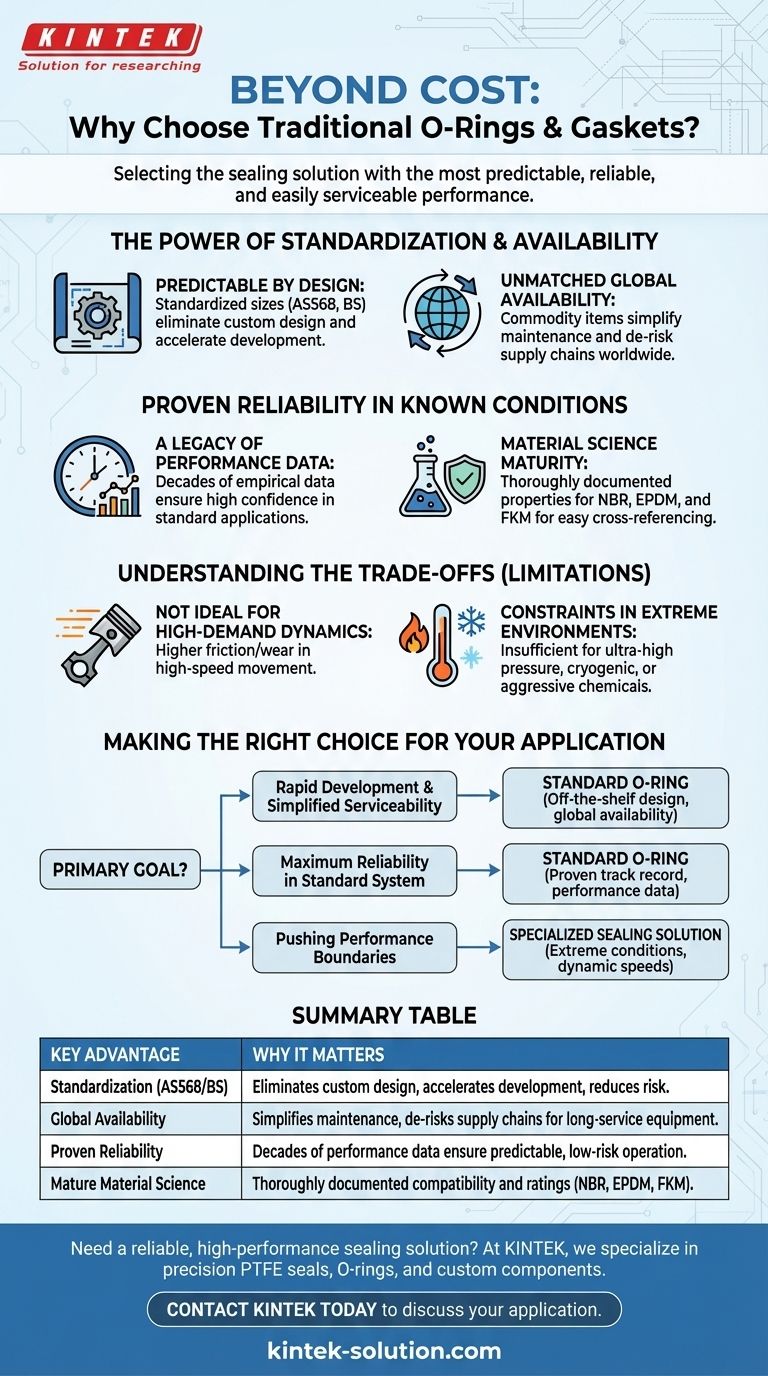

The Power of Standardization and Availability

The greatest strengths of traditional seals often lie outside their direct mechanical function. Their integration into global engineering standards provides immense value that newer, more specialized solutions cannot match.

Predictable by Design

Standardized sizes, such as those defined by AS568 (USA) or BS (British) standards, mean engineers are not starting from scratch. The specifications for the seal's groove or gland are pre-calculated and globally understood.

This eliminates custom design work, reduces the risk of error, and accelerates the development process for a vast number of common applications, like pumps and valves.

Unmatched Global Availability

Because they are standardized, O-rings are commodity items. A standard BS-sized Viton O-ring can be sourced from countless manufacturers and distributors around the world.

This de-risks supply chains and dramatically simplifies maintenance and field repairs. A technician can procure a replacement for a standard pump seal almost anywhere, a critical advantage for equipment with a long service life.

Proven Reliability in Known Conditions

For a majority of industrial and mechanical applications, the operating environment is not on the bleeding edge. In these cases, predictability is far more valuable than novel capability.

A Legacy of Performance Data

Traditional O-rings have been used for decades in nearly every conceivable static and low-speed dynamic application. There is a massive body of empirical data on their performance, wear characteristics, and failure modes.

This history means their reliability in a standard application, like a hydraulic pump, is a known quantity. Engineers can select them with an extremely high degree of confidence, which is the cornerstone of sound engineering.

Material Science Maturity

The material science is exceptionally mature. The chemical compatibility, temperature limits, and pressure ratings for common materials like Nitrile (NBR), EPDM, and Fluoroelastomer (FKM/Viton) are thoroughly documented.

An engineer can easily cross-reference their application's fluid, temperature, and pressure requirements against a chart to find a reliable, off-the-shelf material.

Understanding the Trade-offs

Of course, traditional seals are not the answer for every problem. Understanding their limitations is key to using them effectively.

Not Ideal for High-Demand Dynamics

While used in some dynamic applications, O-rings can suffer from higher friction and wear compared to specialized lip seals or spring-energized seals designed specifically for high-speed or frequent movement.

Constraints in Extreme Environments

For applications involving ultra-high pressures, cryogenic temperatures, or uniquely aggressive chemical combinations, a standard O-ring is likely insufficient. These are the scenarios where more advanced or custom-engineered seals are necessary.

Sensitivity to Installation

The effectiveness of an O-ring is highly dependent on proper groove design and careful installation. Scratches, nicks, or twisting the seal during assembly are common causes of failure that require proper training and procedure to avoid.

Making the Right Choice for Your Application

Choosing the correct seal is about aligning the component's characteristics with your project's primary goal.

- If your primary focus is rapid development and simplified serviceability: A standard O-ring is almost always the correct choice due to its off-the-shelf design requirements and global availability.

- If your primary focus is maximum reliability in a standard system: The proven track record and immense performance data behind traditional O-rings make them the lowest-risk option.

- If your primary focus is pushing performance boundaries: For applications with extreme pressures, temperatures, or dynamic speeds, you should investigate specialized sealing solutions, as a traditional O-ring will likely be the limiting factor.

Ultimately, the right seal is the one that delivers the most predictable performance for the specific job at hand.

Summary Table:

| Key Advantage | Why It Matters |

|---|---|

| Standardization (AS568/BS) | Eliminates custom design, accelerates development, and reduces risk. |

| Global Availability | Simplifies maintenance and de-risks supply chains for long-service equipment. |

| Proven Reliability | Decades of performance data ensure predictable, low-risk operation in standard conditions. |

| Mature Material Science | Thoroughly documented compatibility and ratings for materials like NBR, EPDM, and FKM. |

Need a reliable, high-performance sealing solution?

At KINTEK, we specialize in manufacturing precision PTFE seals, O-rings, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a standard, off-the-shelf part or a custom-fabricated solution from prototype to high-volume production, our expertise ensures a perfect seal for your specific operational context.

Contact KINTEK today to discuss your application and benefit from our precision manufacturing and material science knowledge.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support